Method for preparing core-shell structured intelligent nano hydrogel

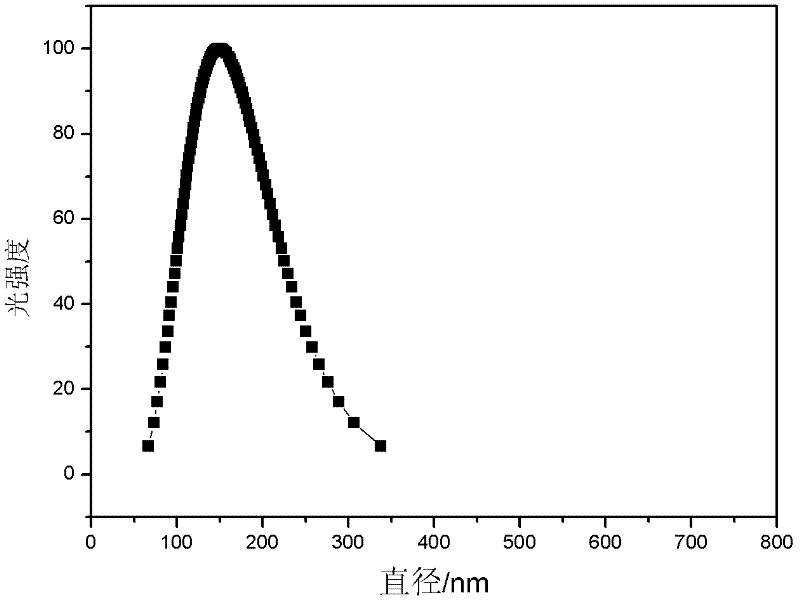

A nano-hydrogel, core-shell structure technology, applied in the field of preparation of smart hydrogel, can solve the problems of difficult removal, harmful to human body, limited application scope of smart hydrogel, etc., and achieves good stability, controllable size, Good effect of dual responsiveness to pH and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

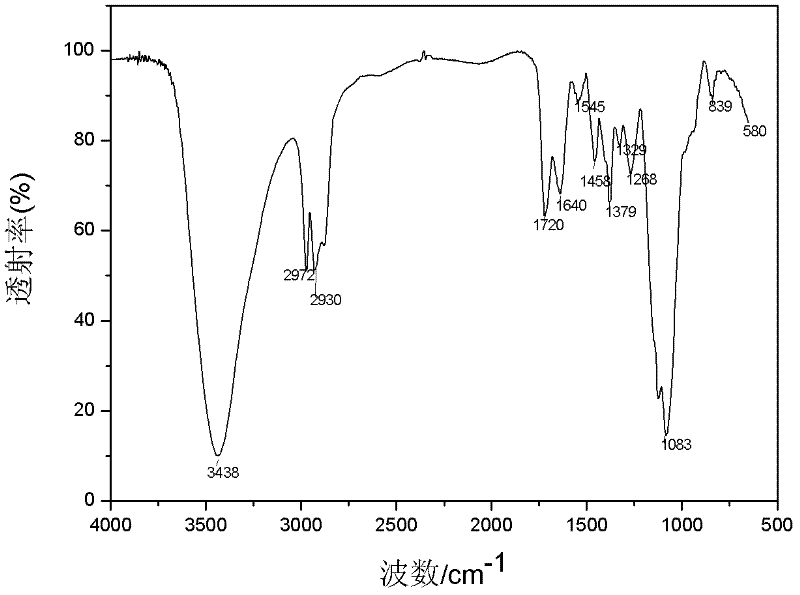

Embodiment 1

[0031] (1) 2g hydroxypropyl cellulose (HPC, Mw=1.0×10 5 ) powder was dissolved in 198g deionized water, stirred by magnetic force for 4 days, and prepared into a solution with a mass fraction of HPC of 1%;

[0032] (2) Dissolve 20g of a solution with a mass fraction of HPC of 1% and 0.30g of methacrylic acid in 74.5g of deionized water, and stir magnetically in water at 24°C for 15 minutes; add 0.10g of BIS, stir magnetically for 15 minutes, and then pass nitrogen gas for 60 minutes ; 0.10g APS was dissolved in 5.0g deionized water, then added to the above-mentioned reaction solution, and nitrogen was continued for 45 minutes; 0.05g TMEDA was added to observe the reaction, and the polymethacrylic acid nano-hydrogel obtained was then dialyzed for 4 days, Then adjust the pH to 3.0 with hydrochloric acid, magnetically stir in water at 24°C, and blow nitrogen gas for 60 minutes to obtain solution A;

[0033] (3) Dissolve 0.50 g of N-isopropylacrylamide and 0.30 g of BIS in 40.0 g...

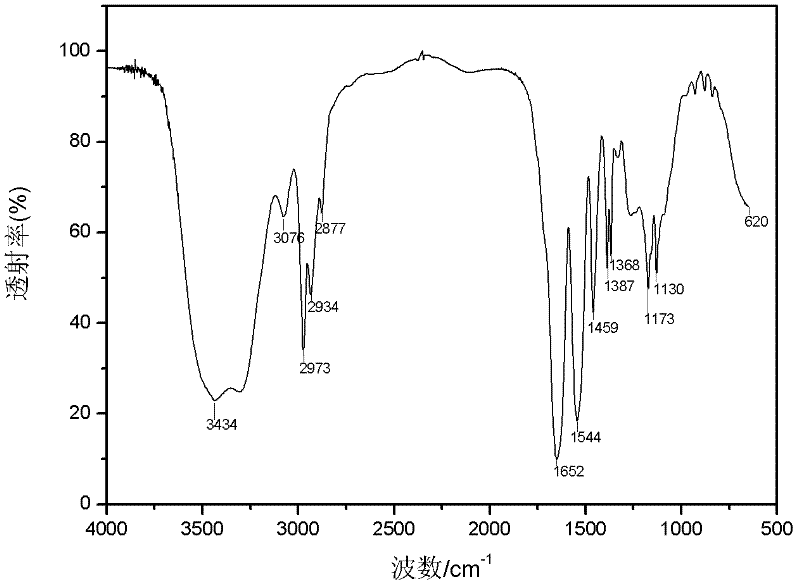

Embodiment 2

[0036] (1) 2g hydroxypropyl cellulose (HPC, Mw=1.0×10 5 ) powder was dissolved in 198g deionized water, stirred by magnetic force for 4 days, and prepared into a solution with a mass fraction of HPC of 1%;

[0037] (2) Dissolve 40g of a solution with a mass fraction of HPC of 1% and 0.30g of methacrylic acid in 90.55g of deionized water, and stir magnetically in water at 24°C for 30 minutes; add 0.10g of BIS, stir magnetically for 30 minutes, and then pass nitrogen gas for 50 minutes ; 0.05g APS was dissolved in 9.0g deionized water, then added to the above-mentioned reaction solution, and nitrogen was continued for 45 minutes; 0.06g TMEDA was added to observe the reaction, and the prepared polymethacrylic acid nano-hydrogel was dialyzed for 6 days. Then adjust the pH to 3.5 with hydrochloric acid, magnetically stir in water at 24°C, and pass nitrogen gas for 60 minutes to obtain solution A;

[0038] (3) Dissolve 1.50g of N-isopropylacrylamide and 0.10g of BIS in 40.0g of dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com