Slow-release pesticide as well as preparation method and application thereof

A technology for slow-release pesticides and pesticides, applied in the field of pesticides, can solve problems such as difficulty in large-scale promotion, complicated preparation process, and limited loading capacity, and achieve good slow-release effects, simple operation, and large loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

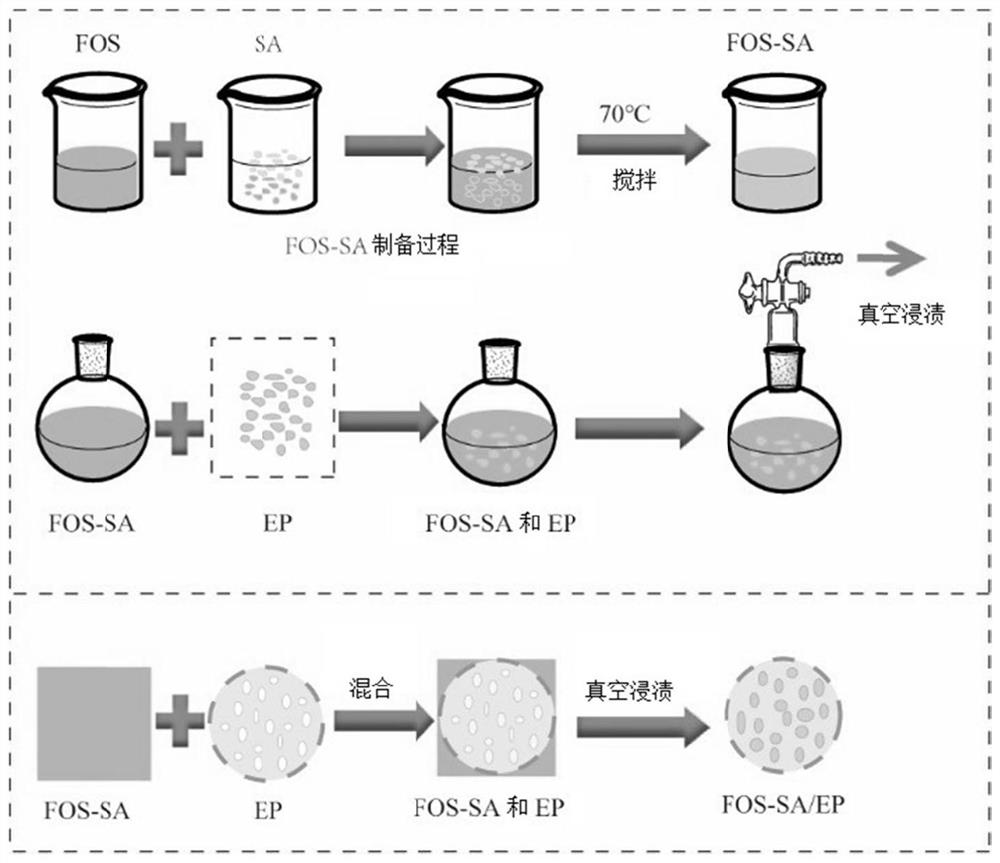

[0061] The present embodiment takes stearic acid as the phase change material as an example, and prepares a series of slow-release pesticides with different stearic acid contents, and the specific process is as follows:

[0062] Weigh thiazophosphine (FOS) and stearic acid (SA) with a melting point of 60°C to ensure that the mass ratios of FOS and SA are 7:3, 6:4, 5:5, 4:6, 3:7 (hard). Fatty acid accounts for 30%, 40%, 50%, 60%, 70% of the mass of the mixture respectively), put it into a beaker, put it into a magnetic stirring heater, melt at 70 ° C, and stir evenly to obtain a thiazophosphine-stearic acid molten mixture (FOS-SA). The oxazophosphine-stearic acid molten mixture and expanded perlite were added to a round-bottomed flask in a mass ratio of 10:1, at 70°C, and stirred evenly. Then connect the hose (with piston) to the circulating water vacuum pump, turn on the vacuum pump, when the vacuum degree reaches 0.09 MPa, continue to evacuate for 1 min, close the piston, an...

Embodiment 2

[0064] In this example, palmitic acid is used as an example to prepare a series of slow-release pesticides with different palmitic acid contents. The specific process is as follows:

[0065] Weigh thiazophosphine (FOS) and palmitic acid (PA) to ensure that the mass ratios of FOS and PA are 7:3, 6:4, 5:5, 4:6, and 3:7 respectively (PA accounts for 30% of the mass of the mixture, respectively. %, 40%, 50%, 60%, 70%), melt at 70° C., and mix with magnetic stirring to obtain thiazophosphine-palmitic acid melt mixture (FOS-FA). Then, the molten FOS-PA and EP were added to the round-bottomed flask in a mass ratio of 10:1, and stirred uniformly at 70 °C. Then connect the round-bottomed flask to the circulating water vacuum pump through a silicone tube (with a piston), when the vacuum degree of the pump reaches 0.09MPa, continue to vacuumize for 1min, close the valve, and soak at 70°C for 1h. After hot filtration, samples were obtained, which were named as FOS-PA / EP-1, FOS-PA / EP-2, F...

Embodiment 3

[0067] In this example, palmitic acid and hydrogenated palm oil are used as phase-change materials as examples to prepare a series of slow-release pesticides with different contents of palmitic acid / hydrogenated palm oil. The specific process is as follows:

[0068] First take by weighing palmitic acid (PA) and hydrogenated palm oil (HPO), ensure that the mass ratios of the two are respectively 4.5:0.5, 4:1, 3:2, put into a beaker, put into a magnetic stirring heater, melt at 70 °C, Stir well to obtain the mixture PA-HPO. Then, weigh the same mass of FOS as the mixture, add it into the mixture PA-HPO, and stir uniformly under magnetic force at 70 °C to obtain a FOS-PA-HPO mixture. FOS-PA-HPO and EP were added to a round-bottomed flask in a mass ratio of 10:1, and stirred uniformly at 70 °C. Then connect the hose (with piston) to the circulating water vacuum pump, turn on the vacuum pump, when the vacuum degree reaches 0.09MPa, continue to vacuumize for 1min, close the piston,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com