Pre-graphitized polycrystalline diamond compact

A technology of polycrystalline diamond and graphitization, which is applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of poor affinity, diamond single crystal falling off, easy falling off, etc. Long service life and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

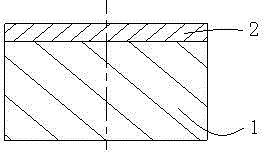

specific Embodiment 1

[0015] The synthesis process is as follows: (1) After the diamond single crystal is cleaned, it is placed in a vacuum furnace and heated at 10 -2 In a vacuum of Pa, heat to 1350°C to make the surface of the diamond single crystal evenly pre-graphitized: (2) Put the graphitized diamond single crystal and the cemented carbide substrate 1 into the pyrophyllite synthesis chamber of the metal cup, Under the pressure of 5Gpa in the synthesis cavity and the cavity temperature of 1000 degrees Celsius, the pre-graphitized diamond single crystal is converted into diamond again under the action of high temperature and high pressure. (3) After the pre-graphitized diamond single crystal is fully transformed and grown into a polycrystalline layer, the temperature in the cavity is increased to 1400 °C, and the cemented carbide substrate 1 The cobalt metal contained in it melts and diffuses to the surface layer between the diamond single crystal polycrystalline layer 2 and the cemented carbid...

Embodiment 2

[0017] The synthesis process is as follows: (1) After the diamond single crystal is cleaned, it is placed in a vacuum furnace and heated to 1400°C in a vacuum of 0.15 Pa to make the surface of the diamond single crystal evenly pre-graphitized: (2) Graphitize The diamond single crystal and the cemented carbide substrate 1 are put into the pyrophyllite synthesis chamber of the metal cup. Under the pressure of 6Gpa in the synthesis chamber and the chamber temperature of 1100 degrees Celsius, the pre-graphitized diamond single crystal is subjected to high temperature and high pressure. Next, it is converted to diamond again, and the graphite on the surface of the diamond single crystal grows into a diamond polycrystalline layer with a dense structure together with the single crystal graphite at the junction while it is converted into diamond; (3) the diamond single crystal to be pre-graphitized After fully transforming and growing into a polycrystalline layer, the temperature in th...

Embodiment 3

[0019] The synthesis process is as follows: (1) After cleaning the diamond single crystal, place it in a vacuum furnace and heat it to 1450°C in a vacuum of 0.02 Pa to make the surface of the diamond single crystal evenly pre-graphitized: (2) Graphitize The diamond single crystal and the cemented carbide substrate 1 are put into the pyrophyllite synthesis chamber of the metal cup. Under the pressure of 7Gpa in the synthesis chamber and the chamber temperature of 1200 degrees Celsius, the pre-graphitized diamond single crystal is subjected to high temperature and high pressure. Next, it is converted to diamond again, and the graphite on the surface of the diamond single crystal grows into a diamond polycrystalline layer with a dense structure together with the single crystal graphite at the junction while it is converted into diamond; (3) the diamond single crystal to be pre-graphitized After fully transforming and growing into a polycrystalline layer, the temperature in the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com