Coal carbonization, oil-gas washing separation and delayed coking combined technology and device

A technology of delayed coking and coal dry distillation, applied in the field of coal chemical industry, can solve the problems of low efficiency, complicated steps and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

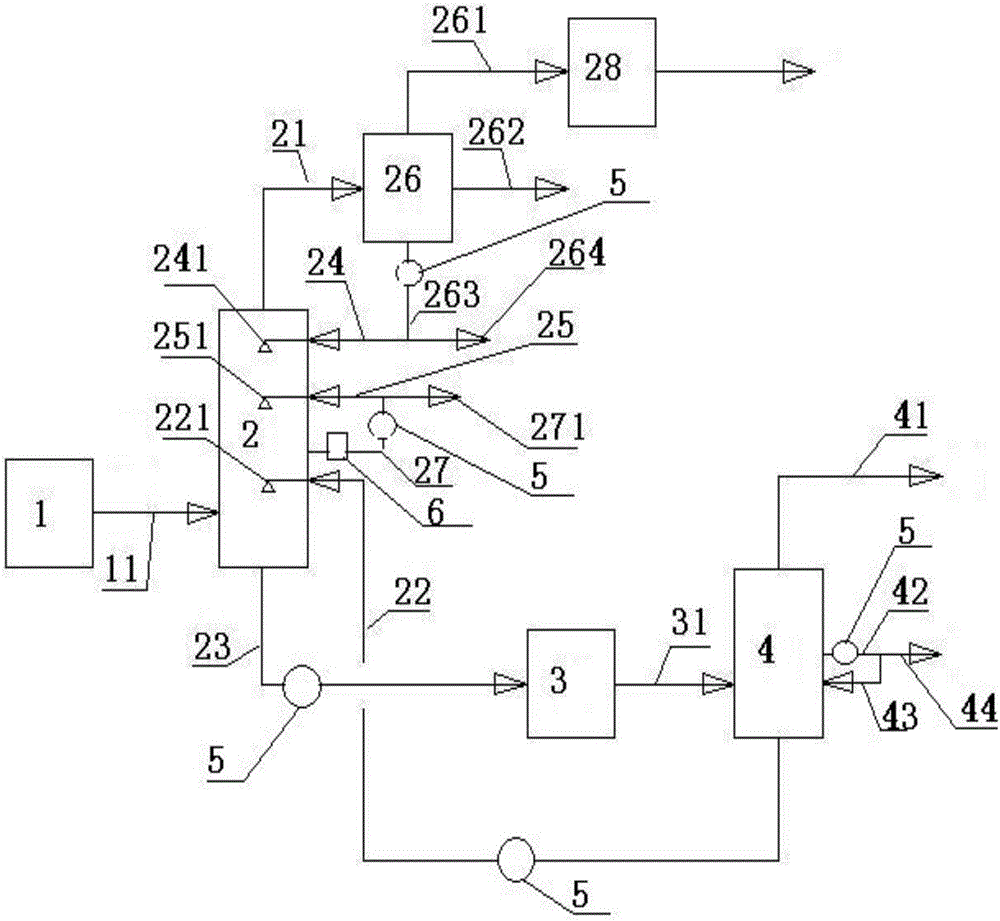

[0041] A coal dry distillation, oil and gas washing separation and delayed coking combined process described in this embodiment includes the following steps:

[0042] 1) Pass the oil gas at 650°C produced by carbonization and pyrolysis of coal in the dry distillation reactor 1 into the washing tower 2 at a flow rate of 10m / s through the gas guide pipe 11 at 750°C for washing and dust removal treatment, and control the top of the washing tower 2 The temperature is controlled at 80°C, the temperature at the bottom of the tower is controlled at 455°C, the pressure at the top of the tower is -1.6KPa, and the pressure at the bottom of the tower is -1.5KPa. The spray medium in the washing tower 2 is the bottom oil of the fractionating tower 4 to obtain the first dedusting Oil-gas mixture and dusty tower bottom oil;

[0043] 2) Send the dust-containing tower bottom oil into the coke tower 3 for delayed coking, control the temperature of the coke tower 3 to be 430° C., the pressure to...

Embodiment 2

[0046] A coal dry distillation, oil and gas washing separation and delayed coking combined process described in this embodiment includes the following steps:

[0047] 1) Pass the oil gas at 395°C produced by coal dry distillation and pyrolysis in the dry distillation reactor 1 into the washing tower 2 at a flow rate of 60m / s through the gas guide pipe 11 at 450°C for washing and dust removal treatment, and control the top of the washing tower 2 The temperature is controlled at 130°C, the temperature at the bottom of the tower is controlled at 395°C, the pressure at the top of the tower is 0.55 MPa, and the pressure at the bottom of the tower is 0.6 MPa. The spray medium in the washing tower 2 is the bottom oil of the fractionating tower 4 to obtain the first oil-gas mixture for dedusting And dusty tower bottom oil;

[0048] 2) Send the dust-containing tower bottom oil into the coke tower 3 for delayed coking, control the temperature of the coke tower 3 to be 390° C., the press...

Embodiment 3

[0051] A coal dry distillation, oil and gas washing separation and delayed coking combined process described in this embodiment includes the following steps:

[0052] 1) Pass the oil gas at 450°C produced by carbonization and pyrolysis of coal in the dry distillation reactor 1 into the washing tower 2 at a flow rate of 20m / s through the air duct 11 at 700°C for washing and dust removal treatment, and control the top of the washing tower 2 The temperature is controlled at 85°C, the temperature at the bottom of the tower is controlled at 400°C, the pressure at the top of the tower is -1.5KPa, and the pressure at the bottom of the tower is -1.4KPa. The spray medium in the washing tower 2 is the bottom oil of the fractionating tower 4, and the first dedusting is obtained. Oil-gas mixture and dusty tower bottom oil;

[0053] 2) Send the dust-containing tower bottom oil into the coke tower 3 for delayed coking, control the temperature of the coke tower 3 to be 390° C., the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com