Digitized liquid level measuring method using laser conduction

A liquid level measurement and digital quantification technology, applied in liquid/fluid solid measurement, measurement device, liquid level indicator, etc., can solve the problems of reducing measurement delay, inappropriate automatic signal adjustment, etc., to reduce measurement delay and wide range of applications , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

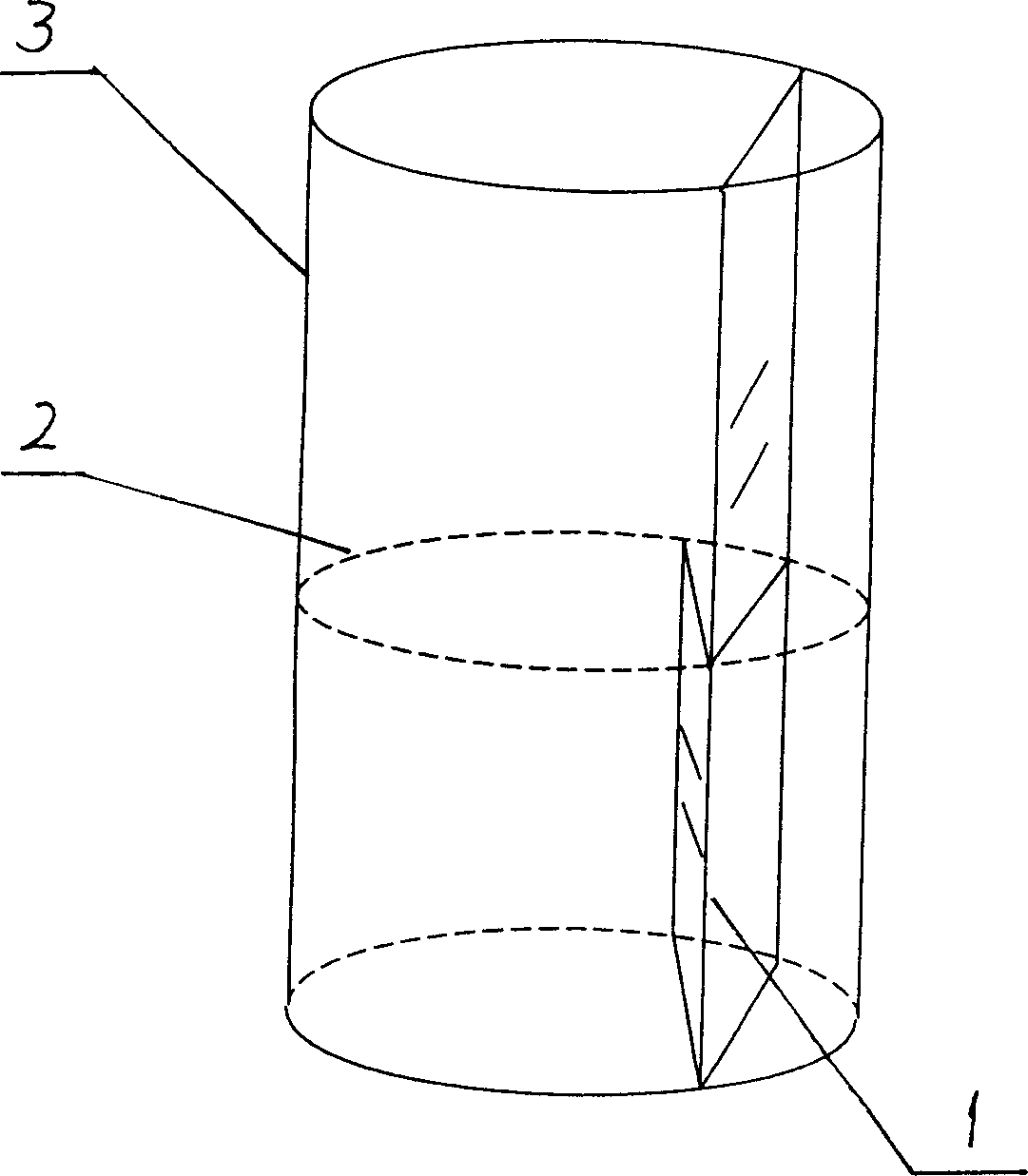

[0026] Example 1, see figure 1 , when the laser beam passes through the transparent liquid 2 of the cylindrical tubular connector, and the incident path 1 of the laser beam does not pass through the axis of the cylindrical tubular connector 3, the light will be horizontally deflected, and the degree of deflection varies with the incidence of the laser beam The distance between path 1 and the axis of the cylindrical tube changes. This is the main theoretical basis of the present invention.

[0027] According to this principle, the liquid level measuring method of the present invention is made up of the following steps:

Embodiment 2

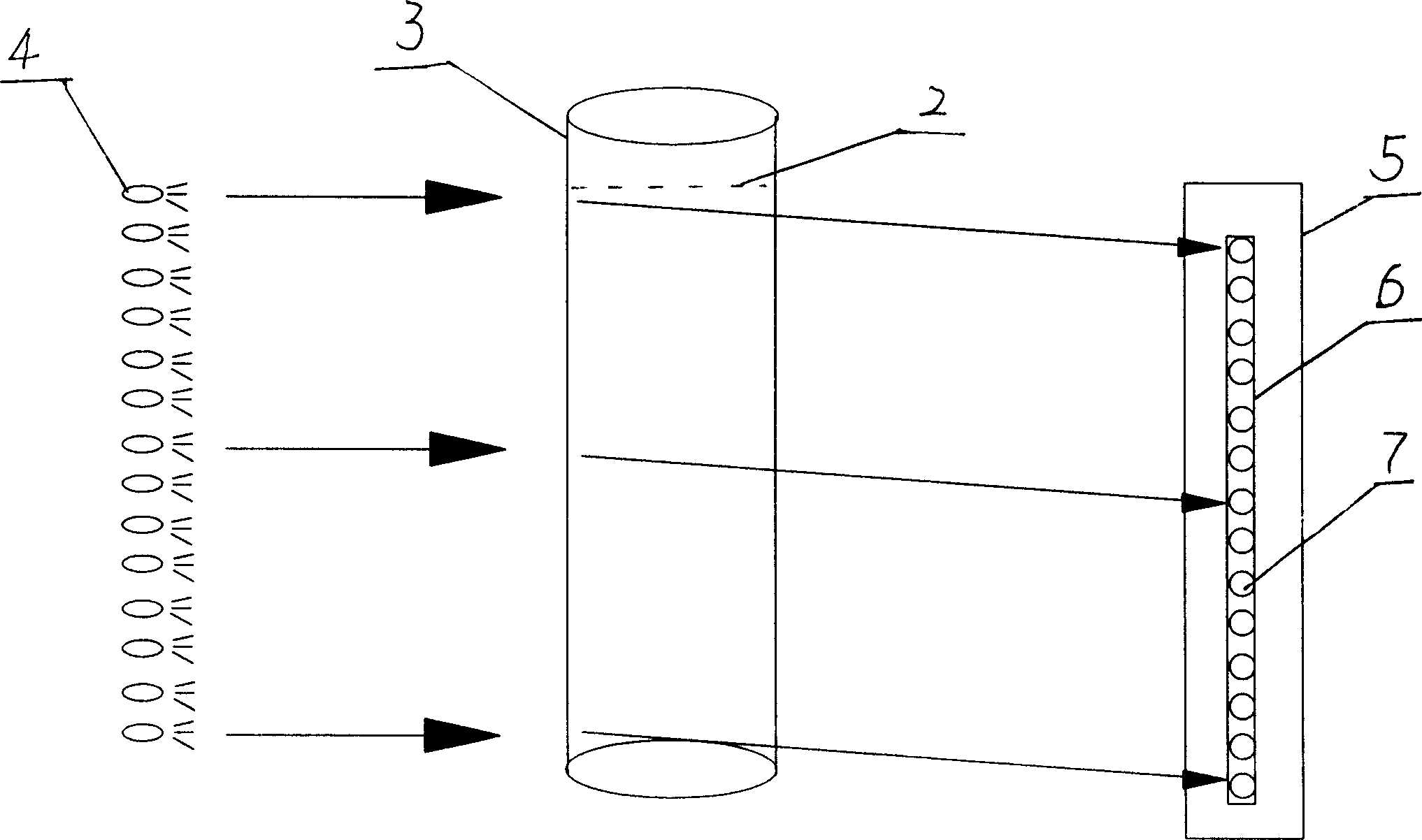

[0028] In embodiment 2, the position of the light bar is used to determine the liquid level. The specific measurement method is: see figure 2 , using a cylindrical tubular transparent (such as glass, or quartz, etc.) connecting sampler 3. Outside the cylindrical tubular transparent connected sampler 3, a row of laser light-emitting tubes (such as laser diodes) is installed along its axial direction as the laser source for short as the laser tube row 4. see figure 2 , image 3 , the height of the laser tube row 4 is equal to the measuring range H of the liquid level 2. In this way, a row of laser beams can pass through the cylindrical tubular transparent connected sampler 3. Note: the path of the laser beam row 4 incident on the cylindrical tubular transparent connected sampler 3 cannot pass through its axis.

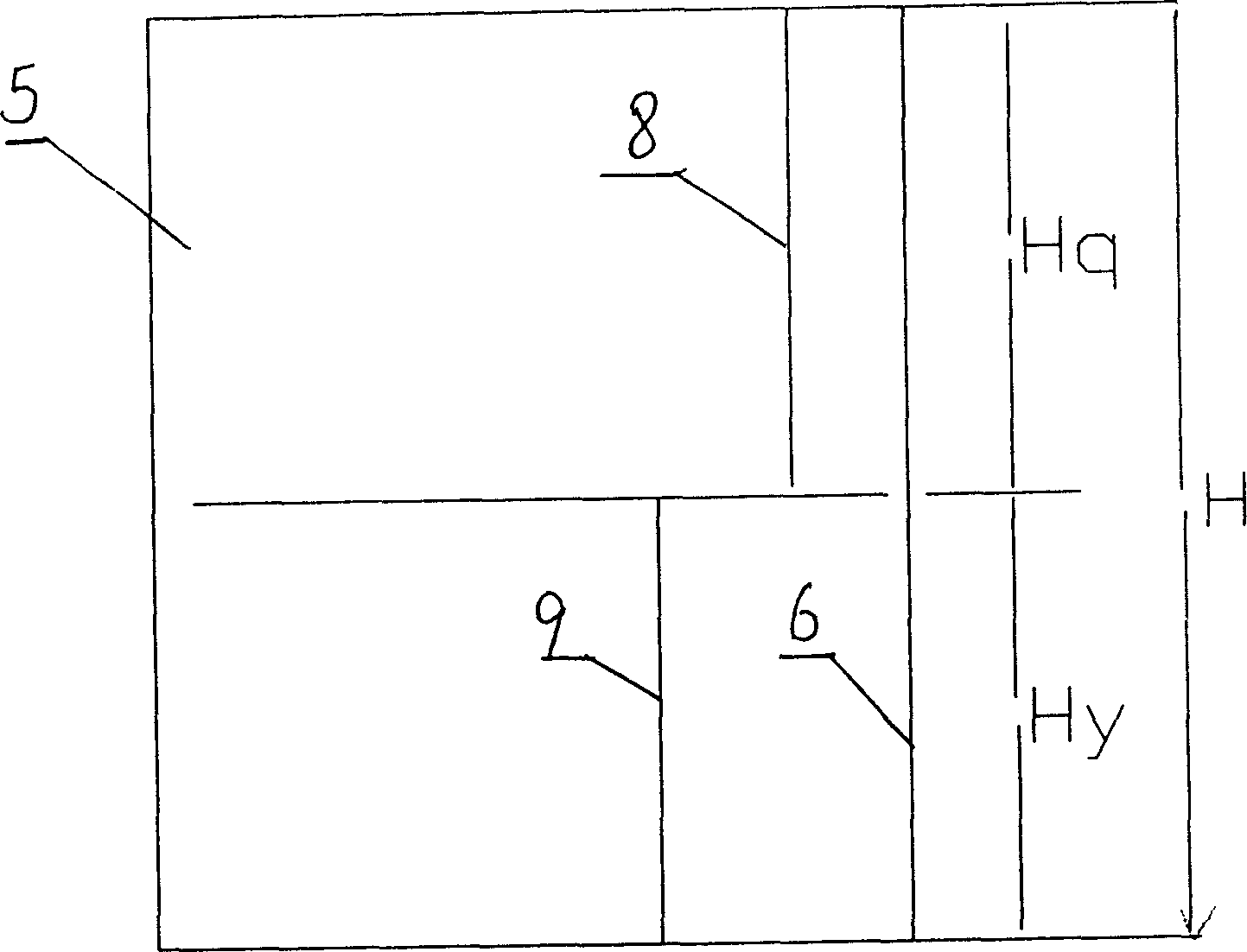

[0029] see figure 2 A background surface 5 with a scale is set on the opposite side of the cylindrical tubular transparent connected sampler 3, and the light emi...

Embodiment 3

[0032] Embodiment 3, using the position of the photosensitive tube to determine the liquid level. see figure 2 , the specific method is: install a row of photosensitive tubes (photosensitive diodes, or photosensitive triodes, etc.) for receiving laser beams at the position of light strip 8 on the liquid surface or light strip 9 under the liquid surface to form a photosensitive tube row 7, and the photosensitive tubes The height of the row 7 is equal to the span H for measuring the liquid level 2 . Opposite to laser tube row 4. If the photosensitive tube row 7 is installed at the position of the light bar 9 under the liquid surface, the photosensitive tubes receiving the laser light are activated, and the positions of these activated photosensitive tubes represent the actual liquid level. If the photosensitive receiving tube row 7 is installed at the "light bar on the liquid surface" position, then on this photosensitive tube row, the positions of the photosensitive tubes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com