Surface treatment method of graphite substrate and preparation method of TaC coating

A technology for graphite substrate and surface treatment, which is applied to the surface treatment method and the preparation of TaC coating, the surface treatment for improving the bonding strength of graphite substrate and TaC coating, and the high-strength bonding field of graphite substrate and TaC coating, which can solve the production cost Low production cycle, short production cycle and other problems, to achieve the effect of short production cycle, strong interface enhancement, and tight integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a kind of surface treatment method that improves the bonding strength of graphite substrate and TaC coating, specifically as follows:

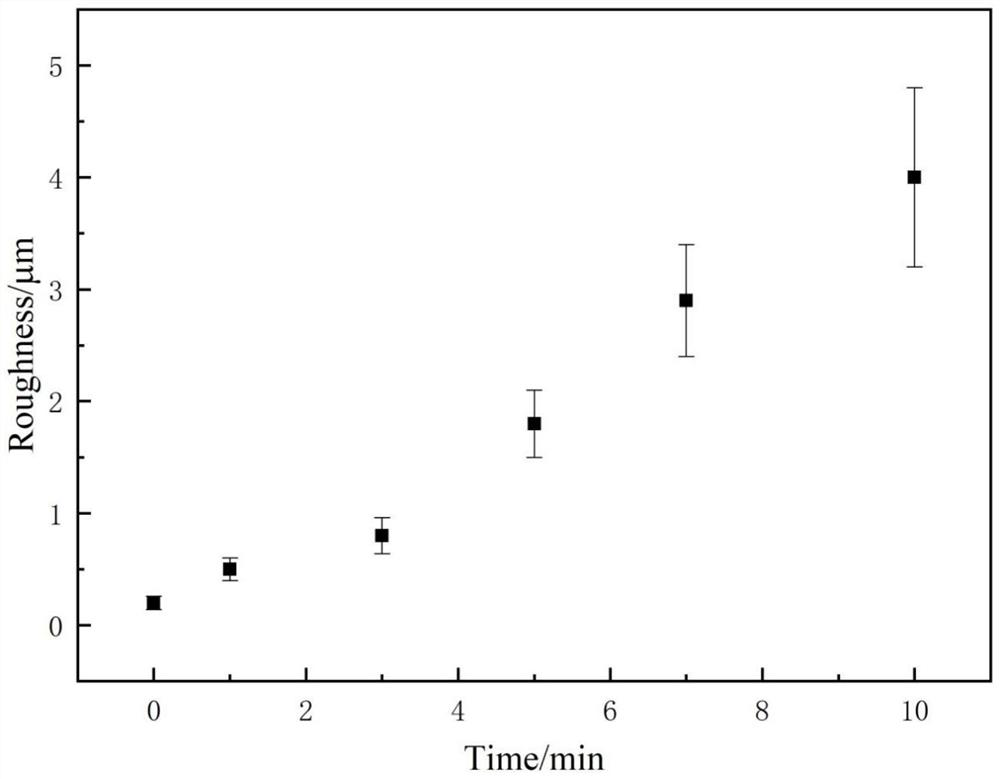

[0034]Clean and dry the graphite substrate, put it into the reaction chamber of the oxygen plasma modification equipment, close the inlet valve of the reaction chamber, evacuate the reaction chamber, then pass in oxygen to fill the reaction chamber, then evacuate, and then fill with oxygen , repeat the steps of inflating and vacuuming twice, finally adjust the inlet valve to stabilize the vacuum degree in the reaction chamber below 50Pa, start the discharge of the radio frequency power supply, the frequency is 13.56Mhz, the power is 1kW, and the oxygen plasma is bombarded on the surface of the graphite substrate. The processing time is 7 minutes; the RF power is turned off, and the surface treatment of the graphite substrate is completed.

[0035] In this embodiment, argon plasma can also be used to bomba...

Embodiment 2

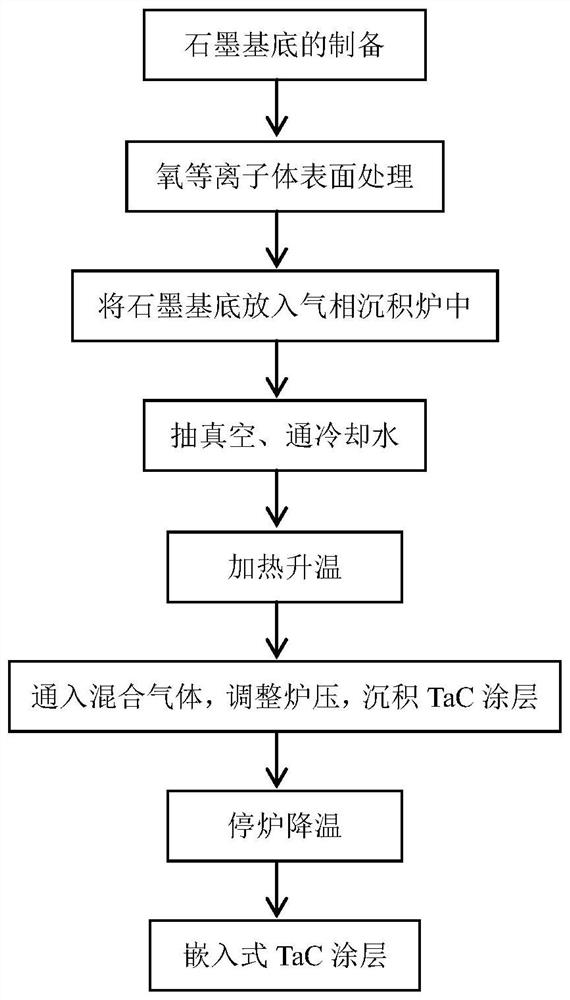

[0038] This embodiment provides a method for high-strength bonding of a graphite substrate and a TaC coating, such as figure 1 , including the following steps:

[0039] S1, graphite substrate is processed through the mode of embodiment 1;

[0040] S2. Put the graphite substrate treated with oxygen plasma into a chemical vapor deposition furnace, evacuate to below 50Pa, and turn on the circulating cooling water to cool the vacuum pump group and the furnace body of the chemical vapor deposition furnace to achieve To protect the furnace body, raise the temperature of the deposition furnace to 1300°C with a heating rate of 5°C / min; when the vapor deposition furnace reaches 1300°C, the 3 h 6 (or CH 4 or C 2 h 6 or C 2 h 2 ), TaCl 5 、H 2 and the mixed gas composed of carrier gas Ar gas to deposit TaC coating, and adjust the deposition thickness by controlling the deposition time. The thickness of the TaC coating prepared in this embodiment is 20-300 μm; wherein, the Ar gas ...

Embodiment 3

[0044] This embodiment provides a method for high-strength bonding of a graphite substrate and a TaC coating, which specifically includes the following steps:

[0045] S1, graphite substrate is processed through the mode of embodiment 1;

[0046] S2. Put the graphite substrate treated with oxygen plasma into a chemical vapor deposition furnace, evacuate to below 50Pa, turn on the circulating cooling water, and raise the temperature of the deposition furnace to 1000°C with a heating rate of 2°C / min; After the furnace reaches 1000°C, pass through the 3 h 6 , TaCl 5 、H 2 and the mixed gas composed of carrier gas Ar gas to deposit TaC coating, and adjust the deposition thickness by controlling the deposition time. The thickness of the TaC coating prepared in this embodiment is 100 μm; wherein, the Ar gas flow rate is 1000ml / min, H 2 The flow rate is 300ml / min, C 3 h 6 The flow rate is 20ml / min, and the furnace pressure in the vapor deposition furnace is maintained at 1000Pa;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com