Control method for gas storage and release processes of fuel supply system employing solid-state storage materials

A fuel supply system and material storage technology, which is applied in the fields of fuel cells, fuel cell additives, and reactant parameter control, etc., can solve the difficulties in finding, limit the development and application of new solid-state storage materials, and the design pattern is insufficient. Solid-state storage material applications, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

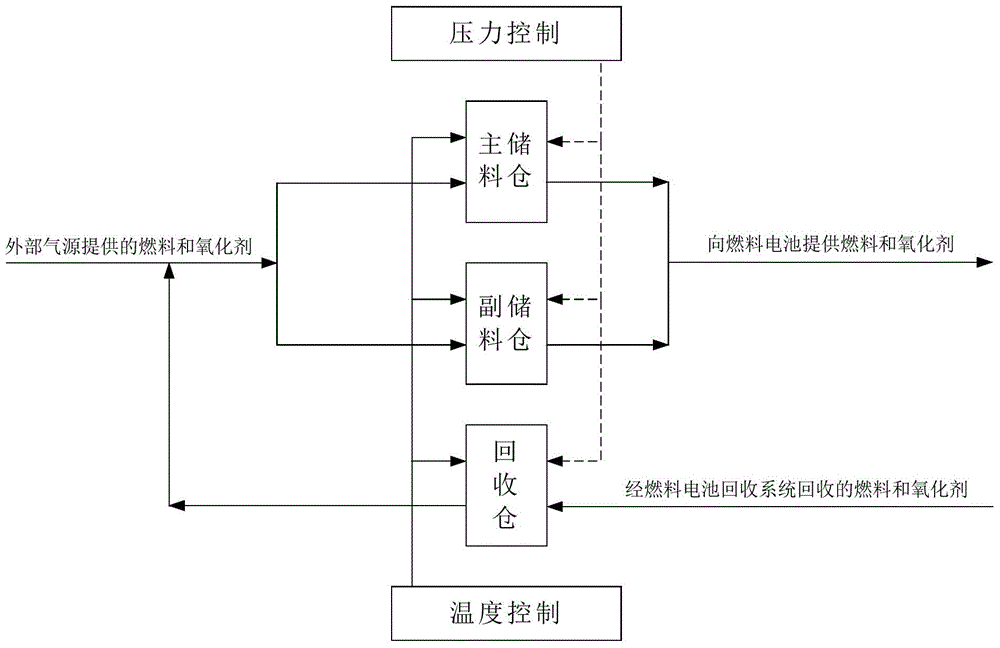

[0056] The control method for the gas storage process of the fuel supply system using solid storage materials proposed by the present invention, the fuel supply system involved in it is shown in the figure figure 1 As shown, the control method includes the control of the gas storage and release process of the main storage bin, auxiliary storage bin and recovery bin, by changing the temperature, pressure, time, etc. of the main storage bin, auxiliary storage bin and recovery bin Kinetic parameters to adjust the storage and release process of the gas in the fuel supply system to provide stable and controllable fuel and oxidant for the fuel cell;

[0057] The method for controlling the gas storage process of the fuel supply system using solid storage materials proposed by the present invention includes the following steps:

[0058] (1) Let the gas enter the main storage bin of the fuel supply system at a flow rate of 50 L / min. The starting time is t A0 , the initial mass of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com