Graded chlorine dioxide generator

A chlorine dioxide and generator technology, applied in the direction of chlorine oxidation, etc., can solve problems such as unfavorable operation and labor liberation, low purity of chlorine dioxide gas, and no safety protection device, etc., so as to reduce the amount of waste liquid generated and improve Raw material conversion rate and effect of reducing sulfuric acid usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

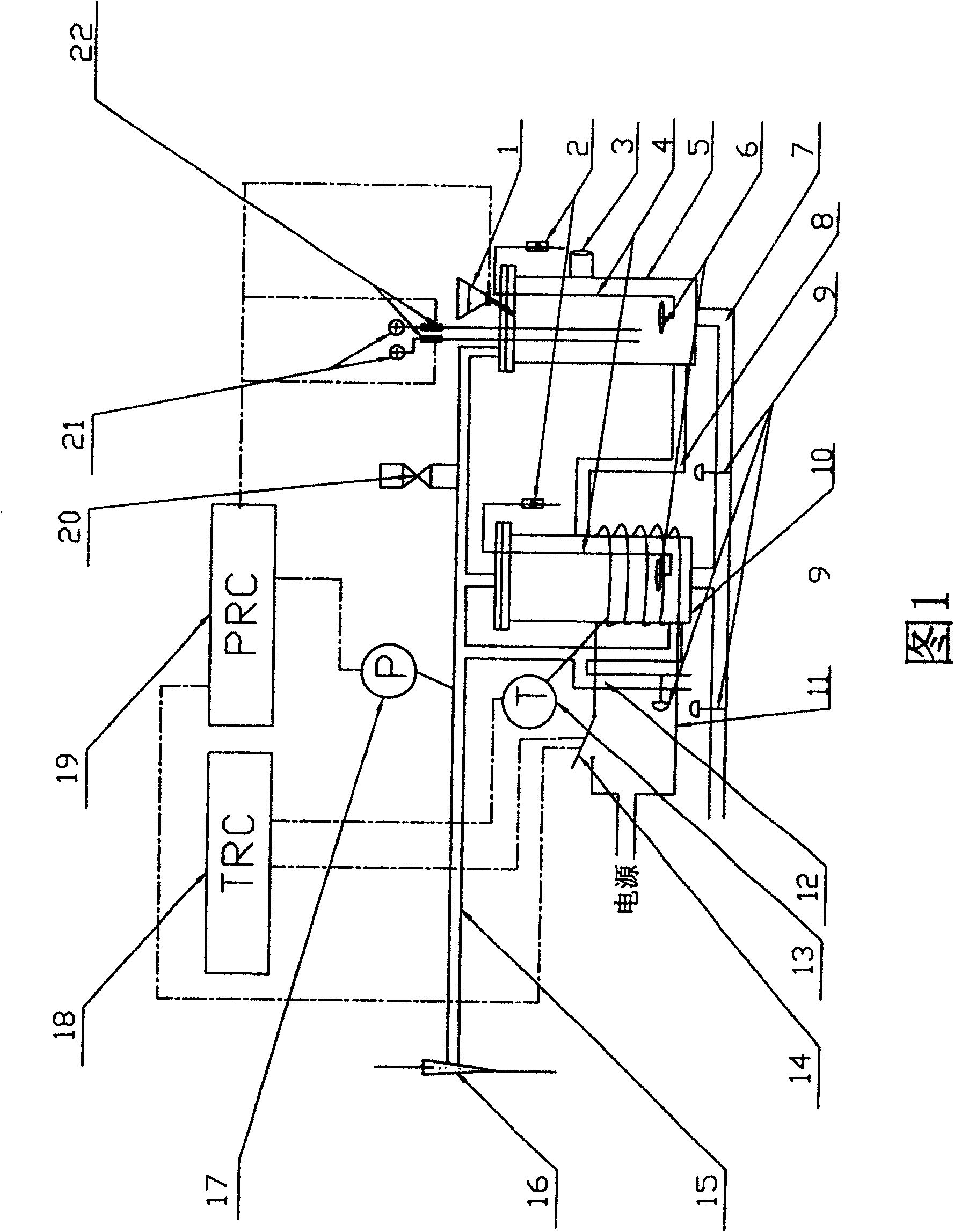

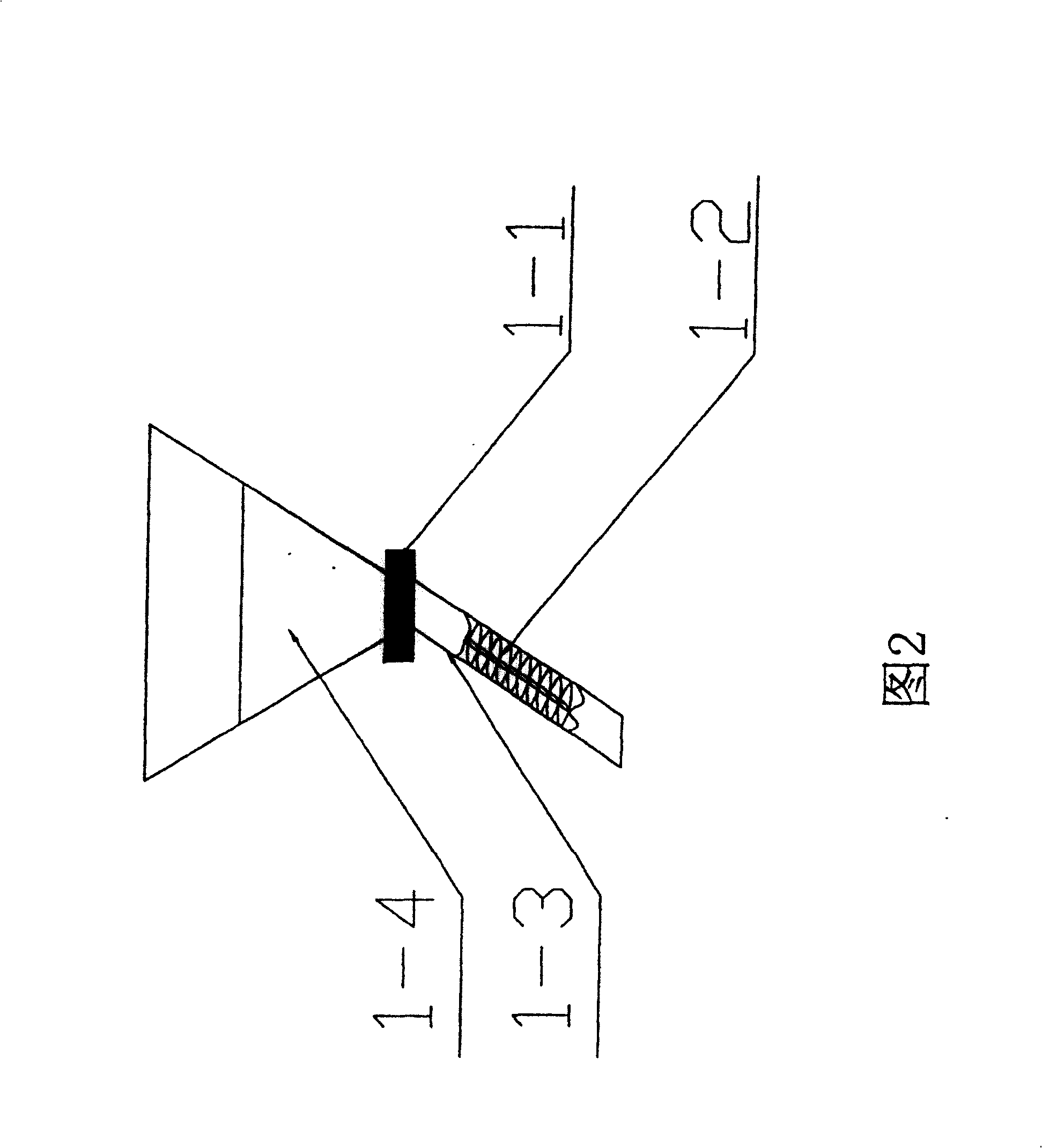

[0027] 30% hydrogen peroxide, 65% sulfuric acid solution and solid sodium chlorate are added respectively to hydrogen peroxide solution storage tank 21, sulfuric acid solution storage tank 21 and feeder hopper 1-4; Open water jet vacuum pump 16, Make the reaction system reach the predetermined negative pressure -0.01MPa; open the air flow meter 2, and feed air at a certain rate (≥10 times the theoretical production of chlorine dioxide); open the heating system 11, and maintain the reaction temperature of the heating reactor at 55°C; Feed automatic controller 19 controls to open metering pump 22 and solid screw feed system 1 feed, feed speed is controlled at: (V H2SO4溶液 / ml): (V H2O2溶液 / ml): (m NaClO3 / g)=2.5:0.7:1, the chlorine dioxide gas that produces is drawn out by water-jet vacuum pump 16 and dissolves in water or absorbing liquid for subsequent use or sells outside.

[0028] Now the sodium chlorate conversion rate is 93%, the chlorine dioxide gas purity is greater than...

Embodiment 2

[0031] 45% hydrogen peroxide, 75% sulfuric acid solution and solid sodium chlorate are added respectively to hydrogen peroxide solution storage tank 21, sulfuric acid solution storage tank 21 and feeder hopper 1-4; Open water jet vacuum pump 16, Make the reaction system reach the predetermined negative pressure -0.03MPa; turn on the air flow meter 2, and feed air at a certain rate (≥10 times the theoretical production of chlorine dioxide); turn on the heating system 11, and maintain the reaction temperature of the heating reactor at 65°C; Feed automatic controller 19 controls to open metering pump 22 and solid screw feed system 1 feed, feed speed is controlled at: (V H2SO4溶液 / ml): (V H2O2溶液 / ml): (m NaClO3 / g)=1.6:0.4:1, the chlorine dioxide gas that produces is drawn out by water-jet vacuum pump 16 and dissolves in water or absorbing liquid for subsequent use or sells outside.

[0032] Now the sodium chlorate conversion rate is 98%, the chlorine dioxide gas purity is greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com