Method for decarburizing from concentrated carbon dioxide emission source based on wet-process regenerated carbon dioxide capture material

A carbon dioxide and capture material technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problems of high cost, high investment and operation costs, and achieve high cost, high regeneration energy consumption, and simple processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

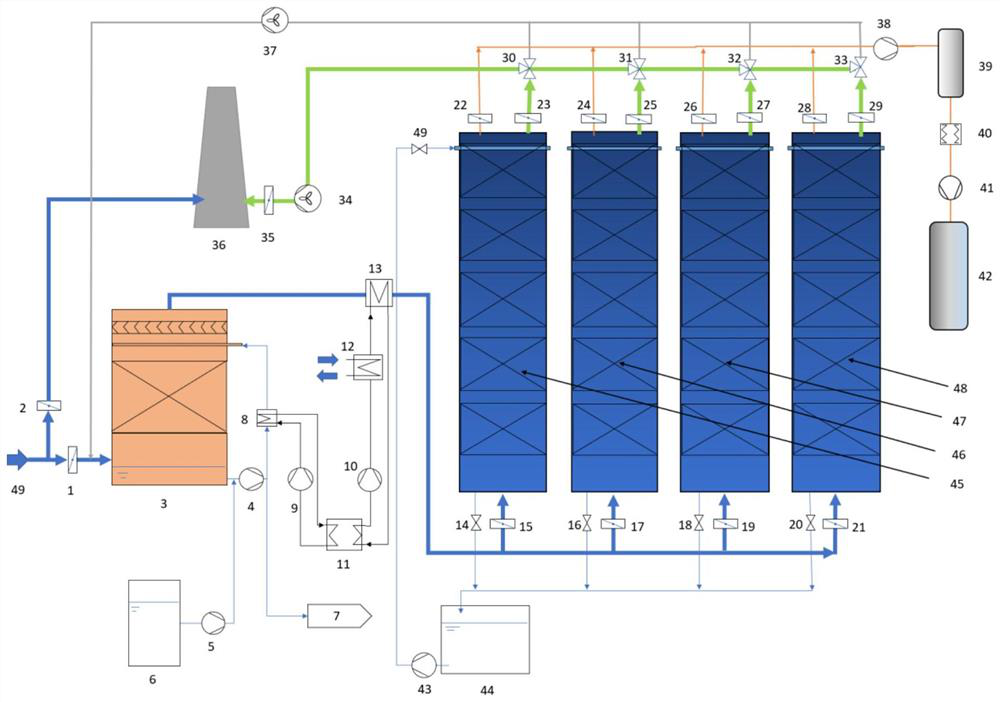

[0057] see image 3 , image 3 The process flow chart of the method for decarbonizing from concentrated carbon dioxide emission sources based on wet regeneration of carbon dioxide capture materials provided by the embodiment of the present invention; wherein, 1, 2, 15, 17, 19, 21, 22, 23, 24 , 25, 26, 27, 28, 29, 35 - gas valve, 3 - direct contact condenser, 4, 5, 9, 10, 43 - pump, 14, 16, 18, 20, 49 - water valve, 30 , 31, 32, 33-gas three-way valve, 34, 37-fan, 38-vacuum pump, 41-compressor, 6-alkali tank, 7-waste water, 8, 12, 13-heat exchanger, 11 -Heat pump, 36-Exhaust tube, 39-Gas buffer tank, 40-Dehumidifier, 42-CO2 storage tank, 44-Circulating water tank, 45, 46, 47, 48-Carbon with wet regeneration CO2 capture material Capture unit, 49 - flue gas inlet.

[0058] The specific working process is as follows:

[0059] Flue gas from industrial processes (including but not limited to concentrated CO in power plants, steel mills, cement plants, chemical plants, etc. 2 em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com