A method for decarbonizing converter and/or blast furnace gas

A blast furnace gas and converter technology, applied in the field of decarbonization of converter and/or blast furnace gas, can solve the problem of separation and recovery of no carbon dioxide gas, and achieve the effect of increasing the cost of decarbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

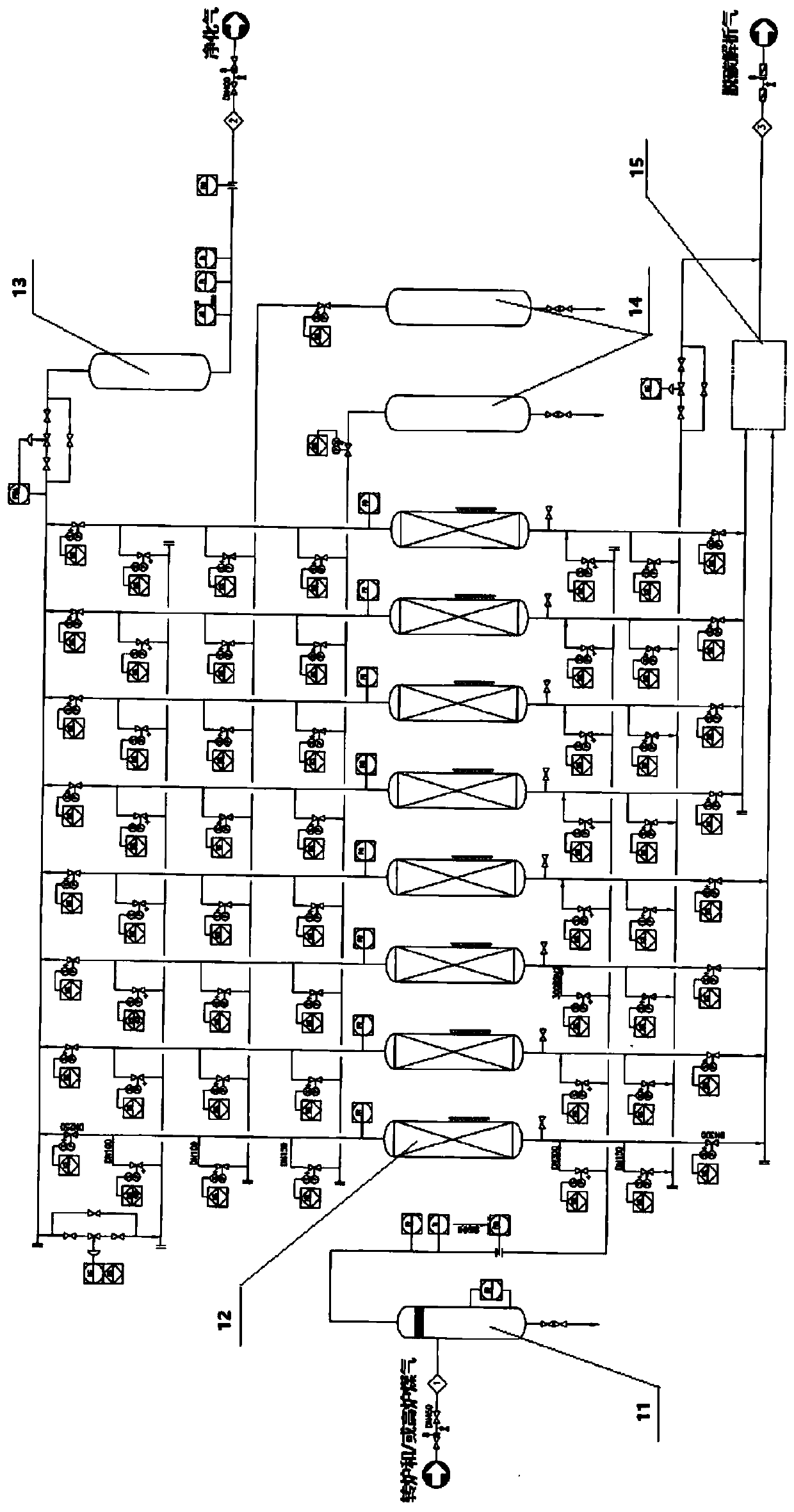

Embodiment 1

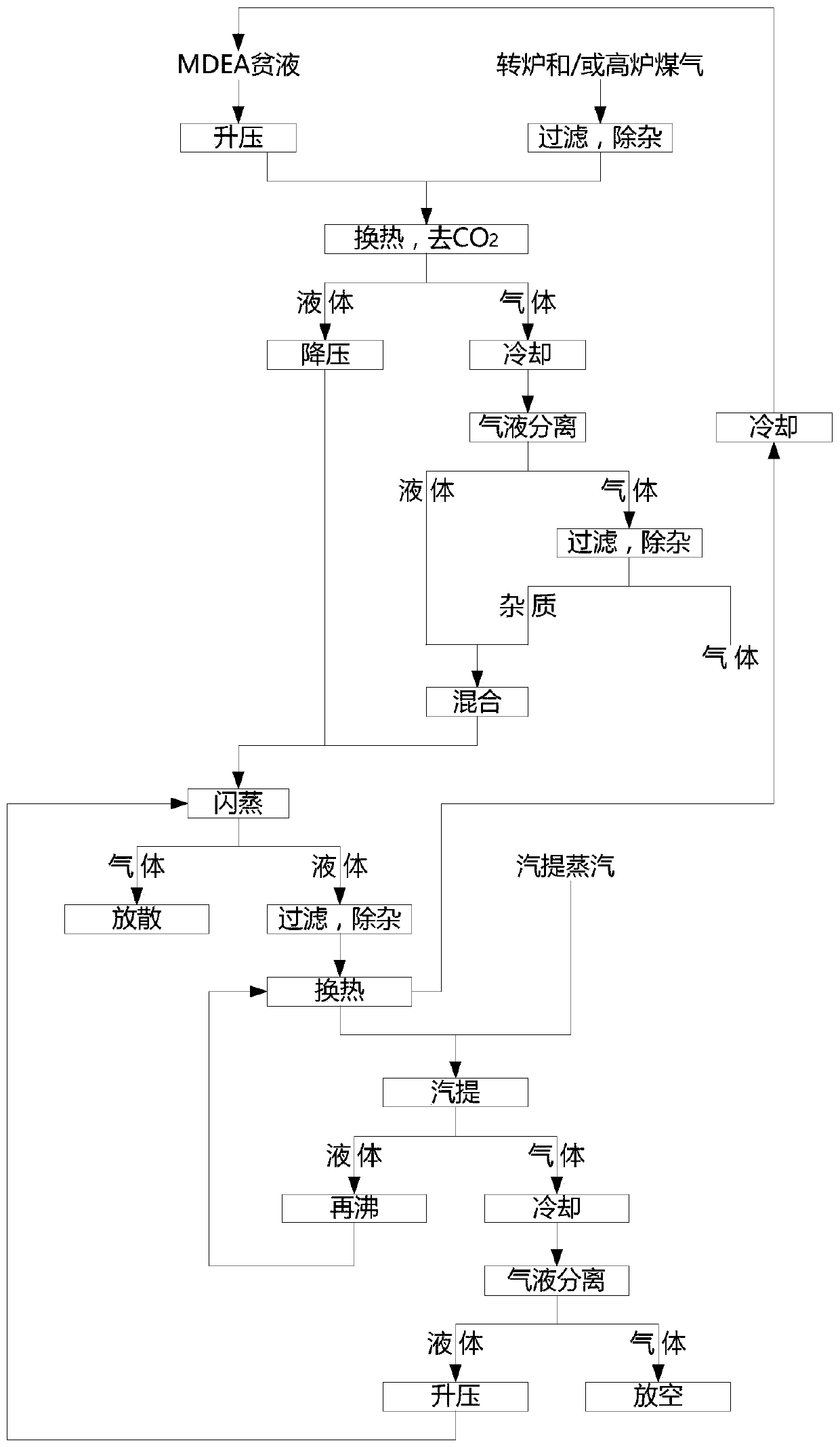

[0142] A method for decarbonizing converter and / or blast furnace gas, comprising the steps of:

[0143] S0), primary purification of converter and / or blast furnace gas

[0144] The flow rate of converter and / or blast furnace gas before primary purification is 29000Nm 3 / h, the pressure is 0.005Mpa, and the temperature is 20°C; among the active ingredients, the volume fraction of carbon monoxide is 48%, the volume fraction of carbon dioxide is 24.5%, the volume fraction of nitrogen is 24.37%, and the volume fraction of hydrogen is 2%, the volume fraction of oxygen is 1%; the content of phosphine is 200mg / kg, and the content of tar and dust is 0.015g / Nm 3 , the content of sulfide is 17.7mg / Nm 3 .

[0145] Primary purification of converter and / or blast furnace gas includes the following steps:

[0146] S01), dust removal and tar removal

[0147] Use an electric tar catcher to dedust and detar the converter and / or blast furnace gas, so that the total amount of dust and tar in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com