Patents

Literature

41results about How to "Low surface load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Retaining member

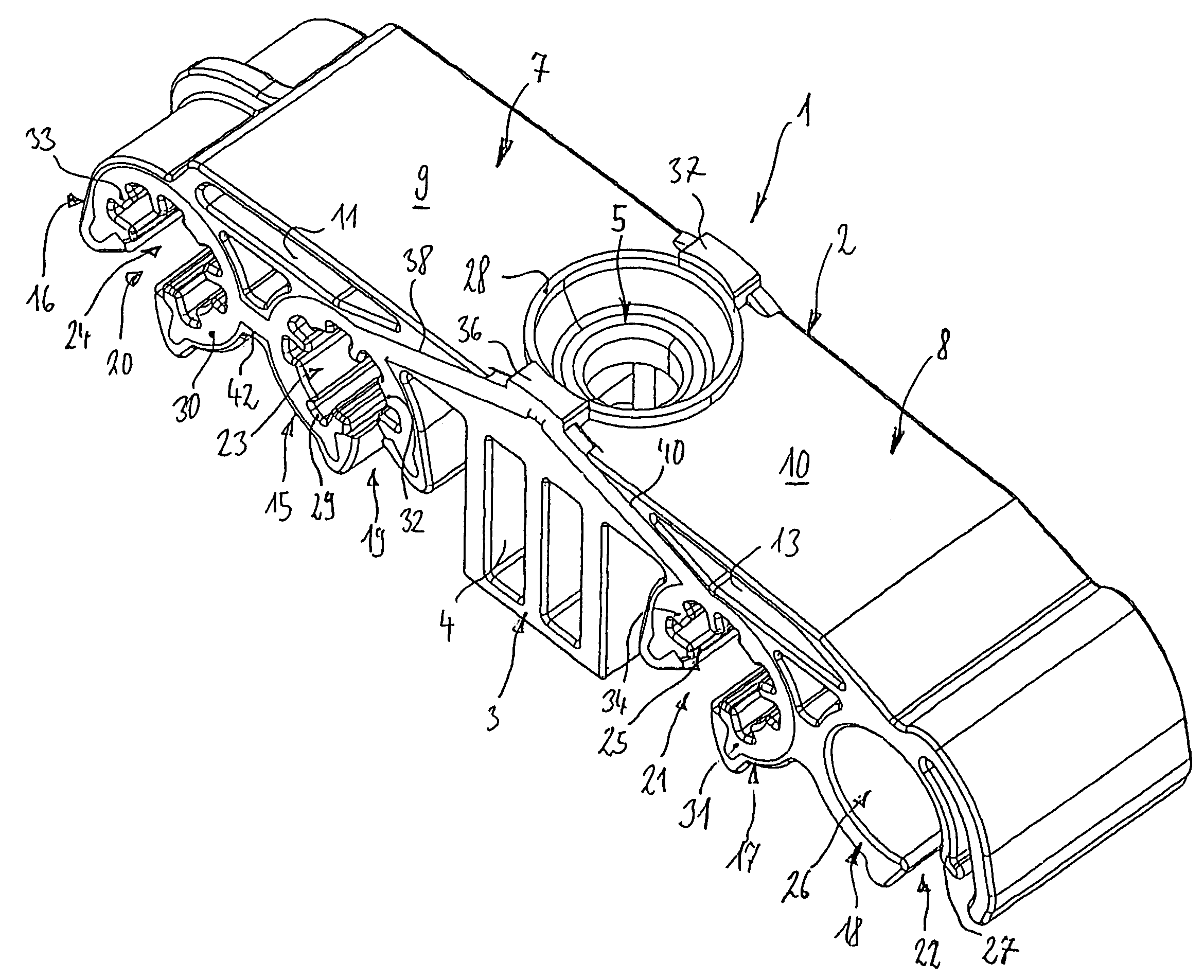

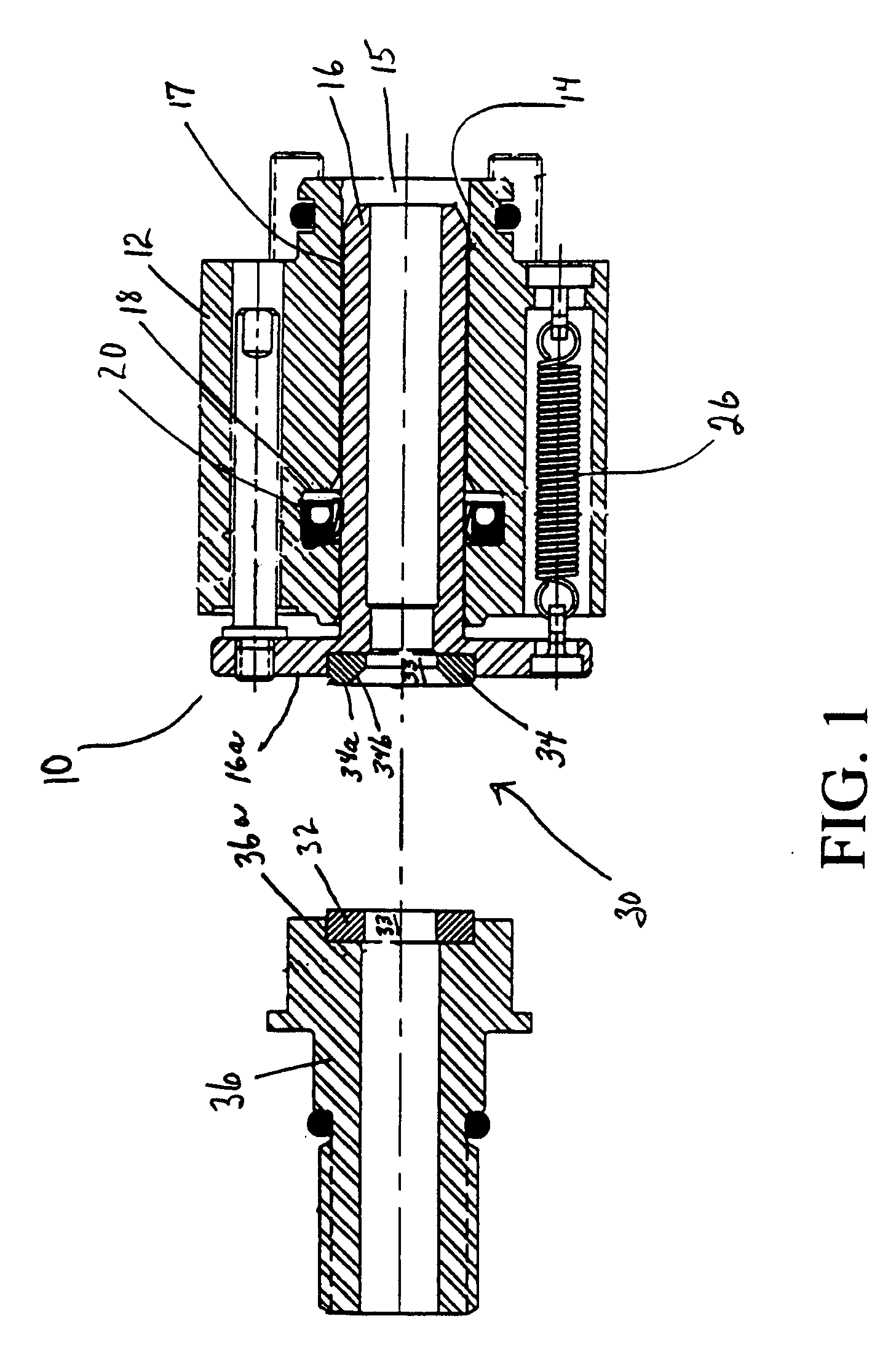

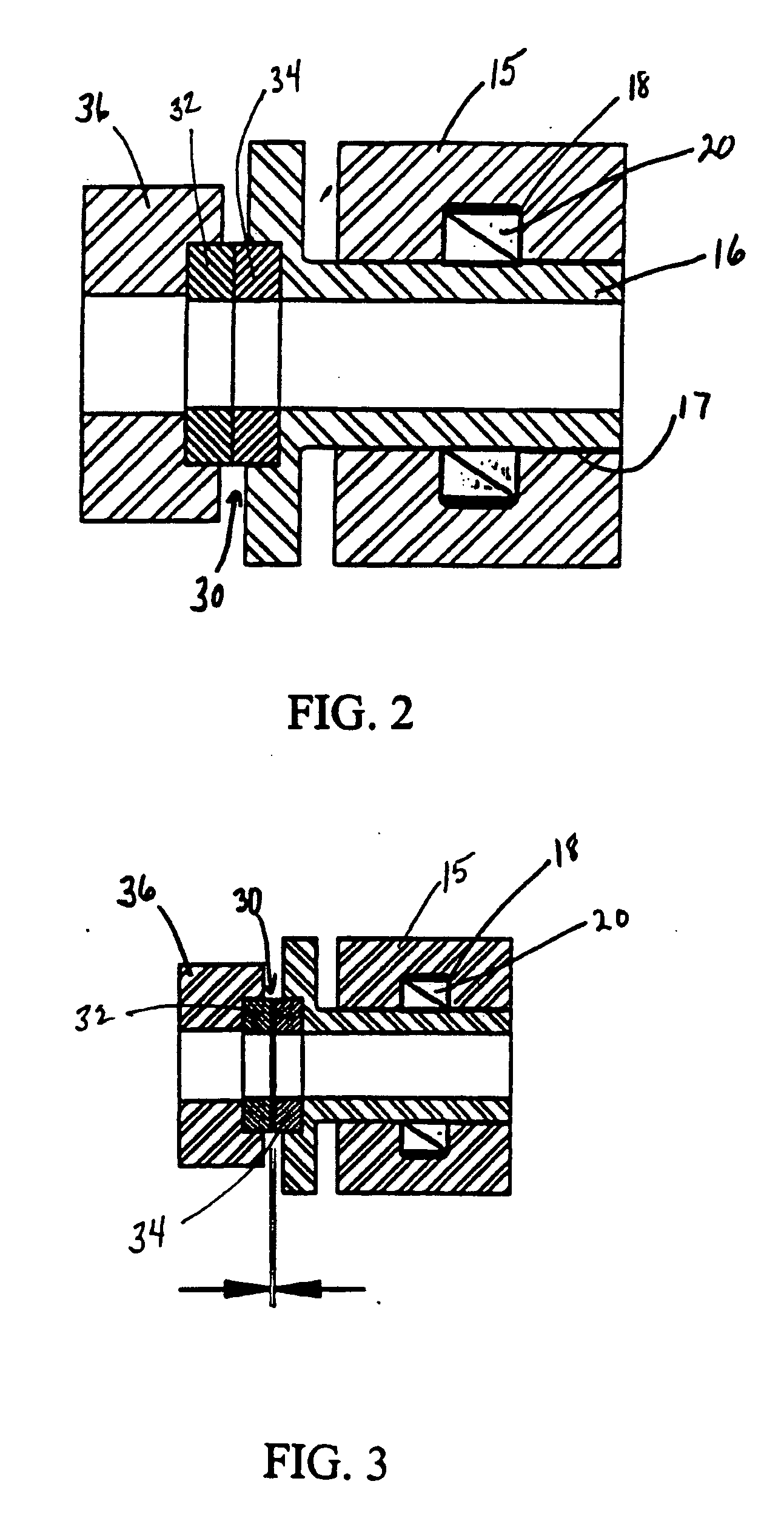

ActiveUS7267307B2Improve isolationSpring constantPipe supportsNon-rotating vibration suppressionEngineeringMechanical engineering

Owner:ITW AUTOMOTIVE PRODS

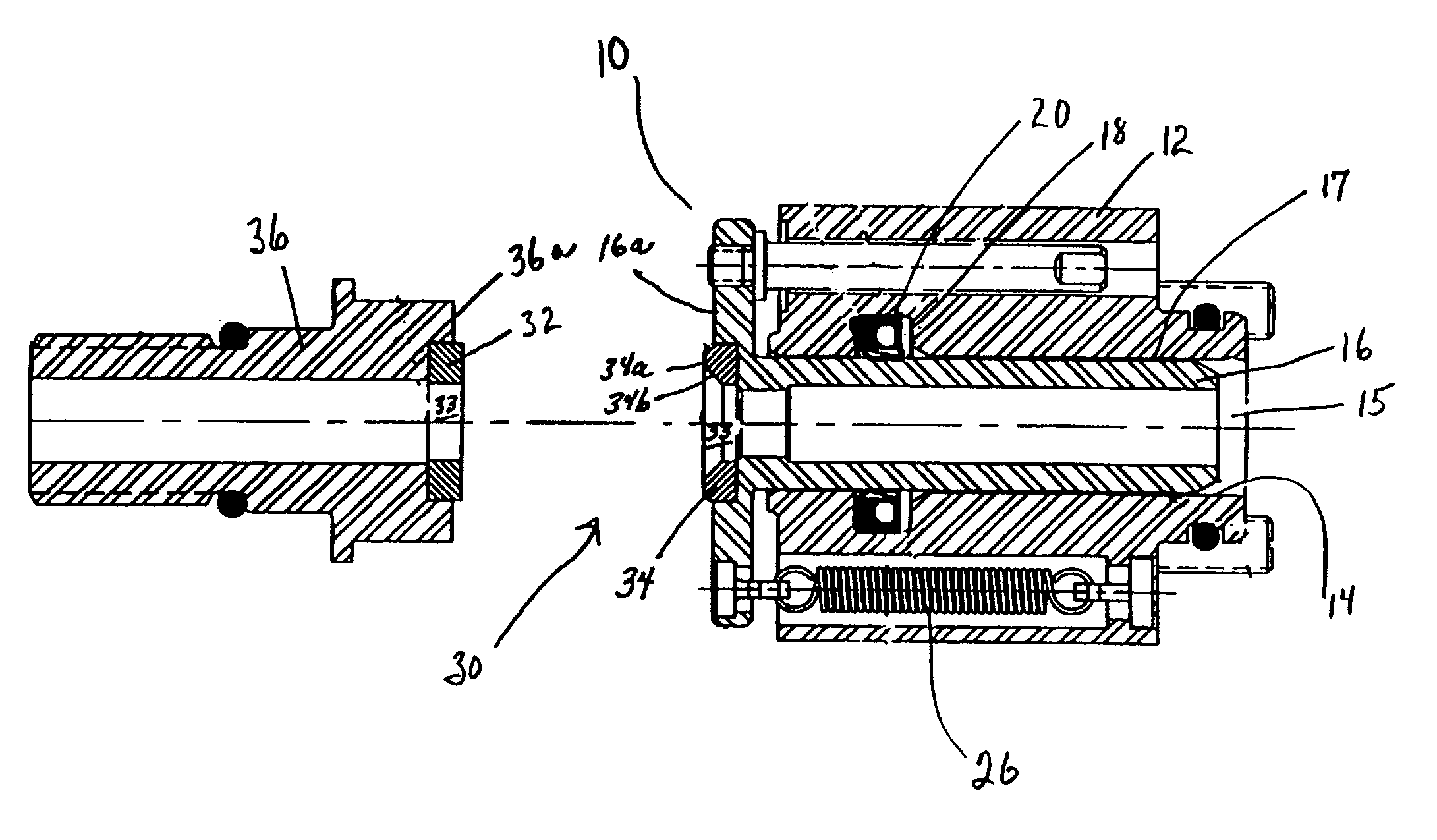

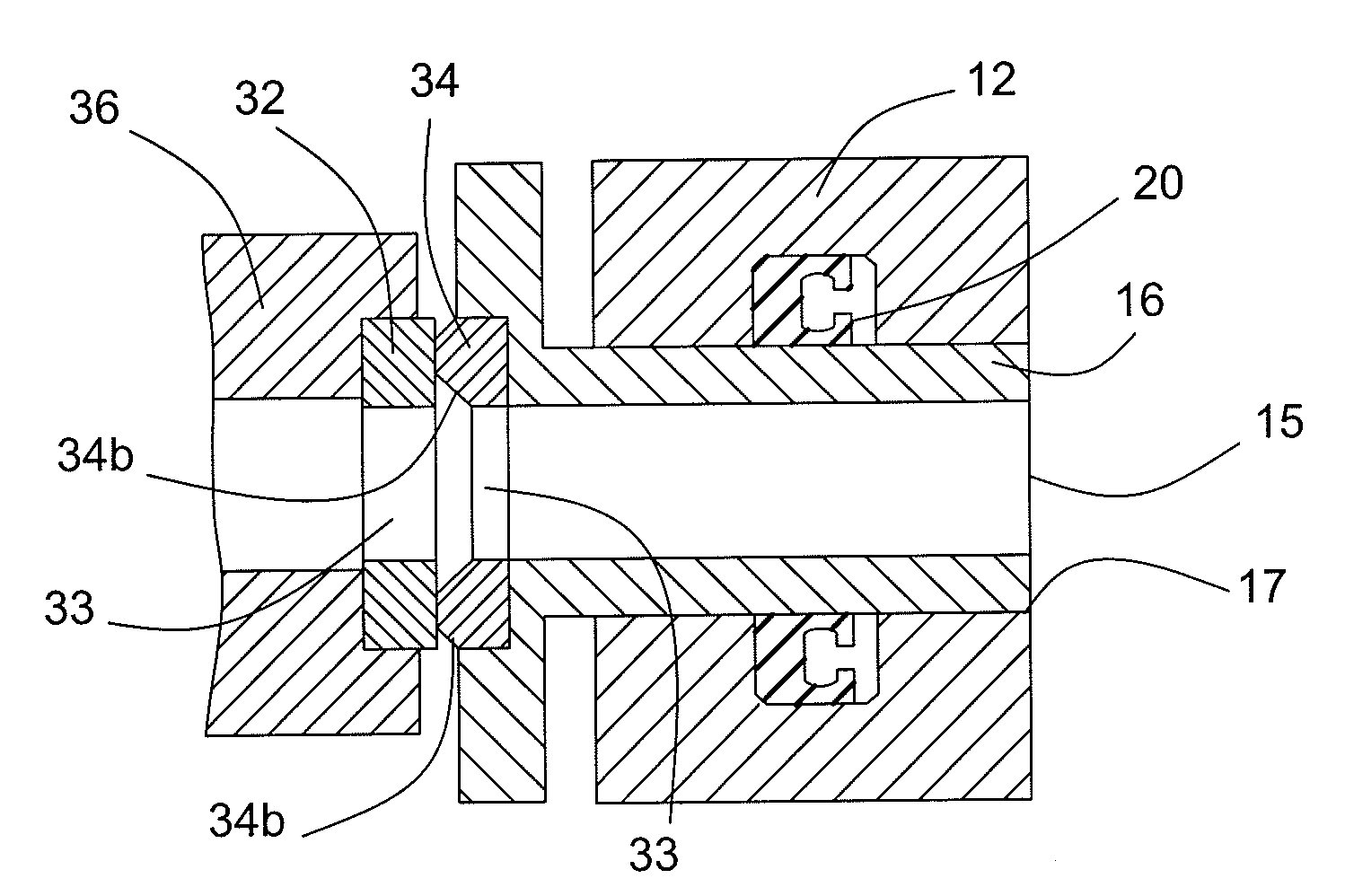

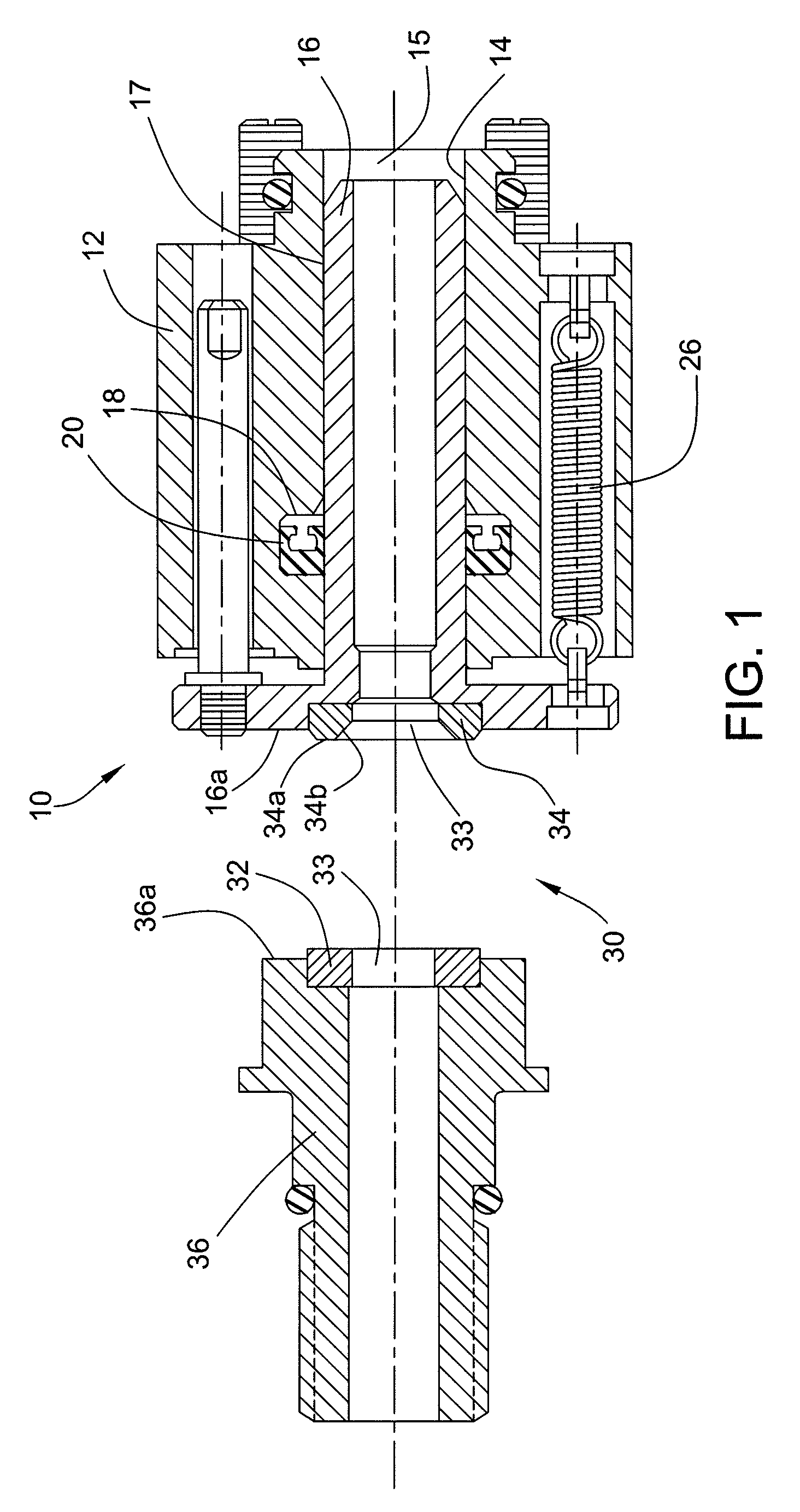

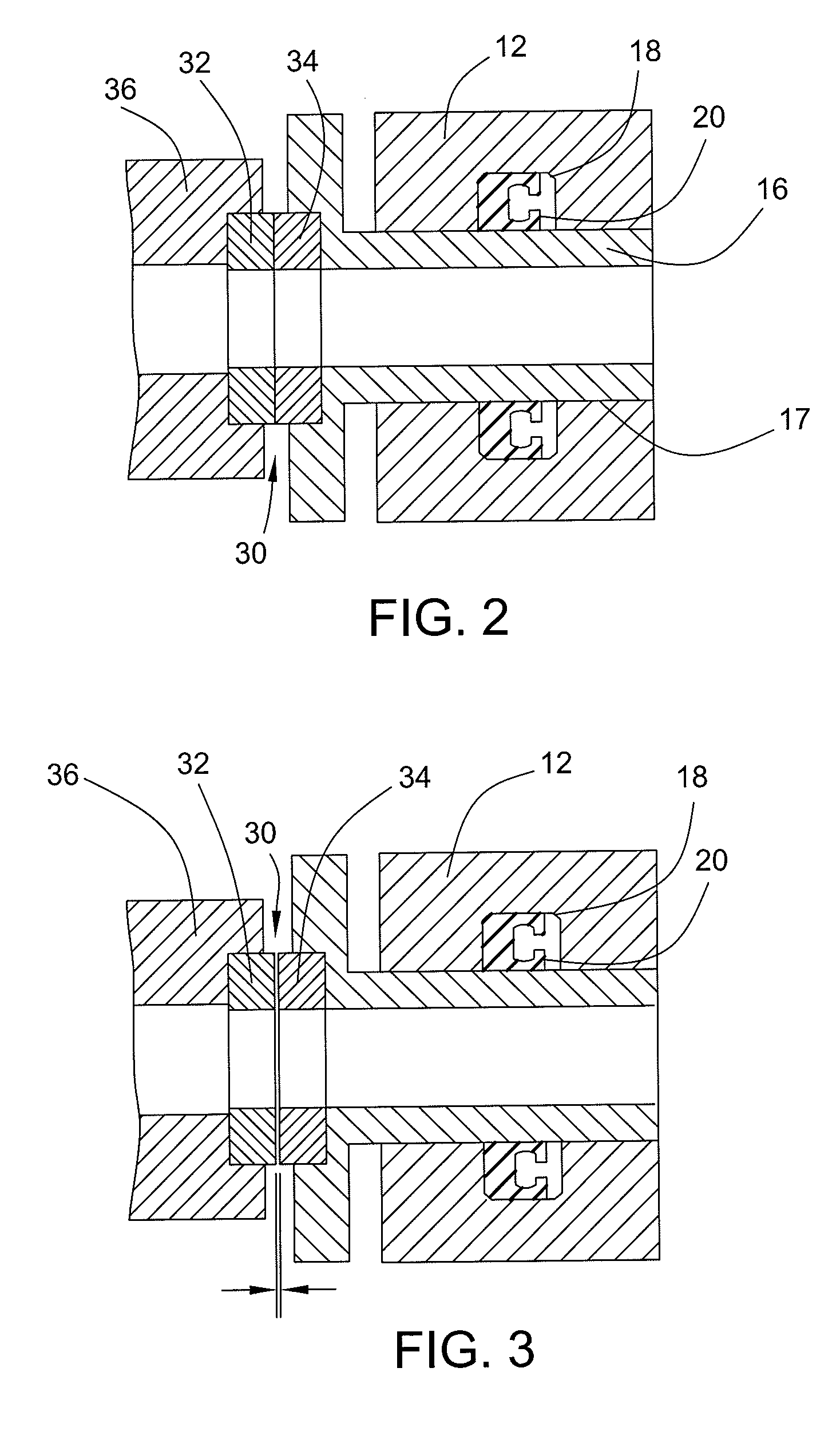

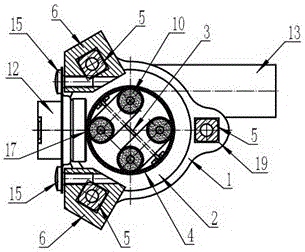

Multi-media rotary union

ActiveUS20060273579A1Reduce in quantityPrevent undesirable leakageSleeve/socket jointsEngine sealsEngineeringCounterbore

A rotating union communicates with a rotor member and is operable with either compressible or incompressible coolant media that enters the union through a media inlet. The union includes a housing having a counterbore and a tubular carrier member axially moveable in the housing. The union includes a primary seal assembly having a rotating seal member mounted to the rotor member and a non-rotating member mounted to the carrier member and a secondary seal member positioned about the carrier member. The range of the balance ratio of the primary seal assembly is disclosed when the primary seal assembly has imposed upon it a closing force, an opening force or no force.

Owner:DEUBLIN

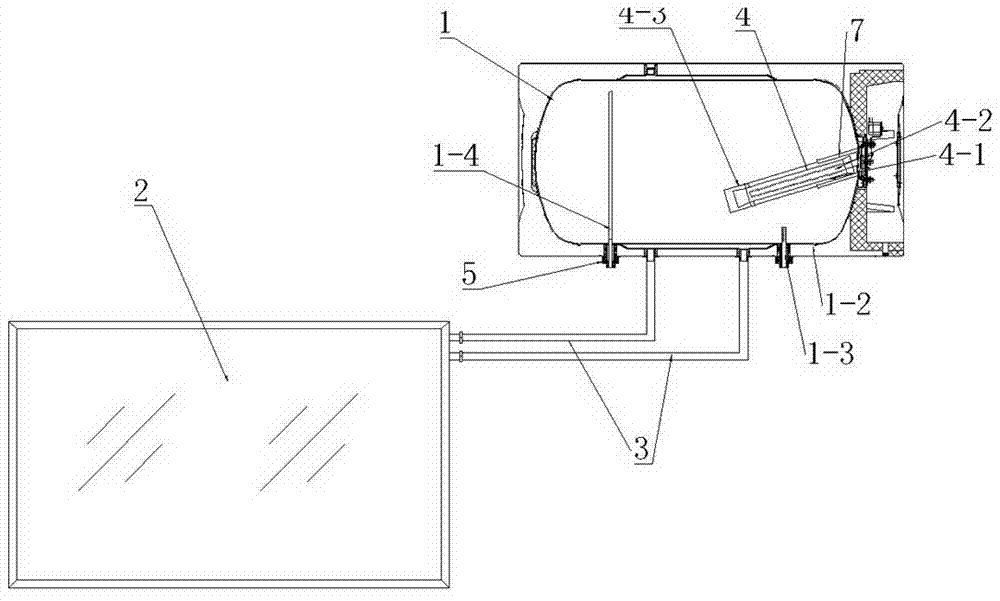

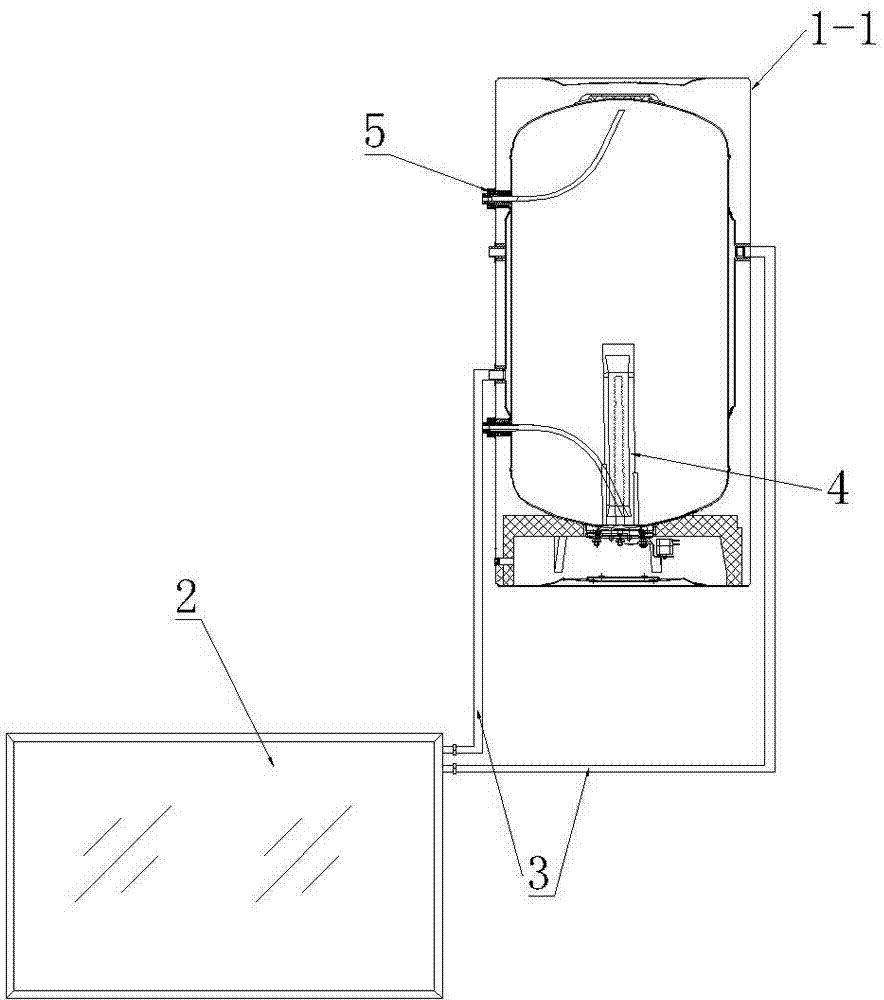

Solar water heater

ActiveCN103363677AHigh outputImprove water temperature stratification effectSolar heat devicesSolar thermal energy generationElectricitySolar water

The invention discloses a solar water heater comprising a water heater body. The water heater body is connected with a solar heat collector which comprises a shell, an inner container, a water inlet pipe, a water outlet pipe and a main controller. The solar water heater is characterized in that the inner container is provided with an optical wave heater, the optical wave heater is composed of a quartz tube, an electric heating wire and a sheath, and the quartz tube is hermetically fixed in the sheath. The solar water heater is simple in structure and capable of realizing water and electricity separation, purifying water and inhibiting bacteria, and has a good popularization value, and service life of the solar water heater is prolonged.

Owner:GUANGDONG MACRO GAS APPLIANCE

Multi-media rotary union

ActiveUS7815224B2Reduce in quantityPrevent leakageSleeve/socket jointsEngine sealsEngineeringCounterbore

Owner:DEUBLIN

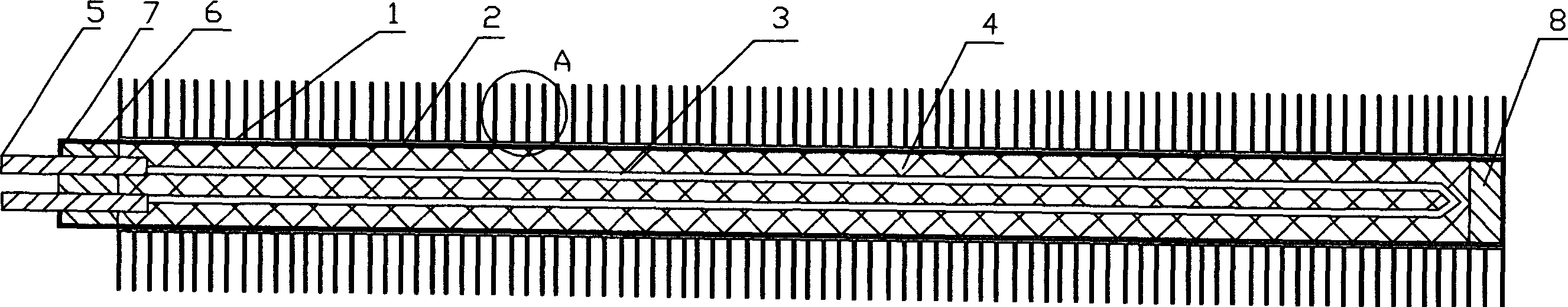

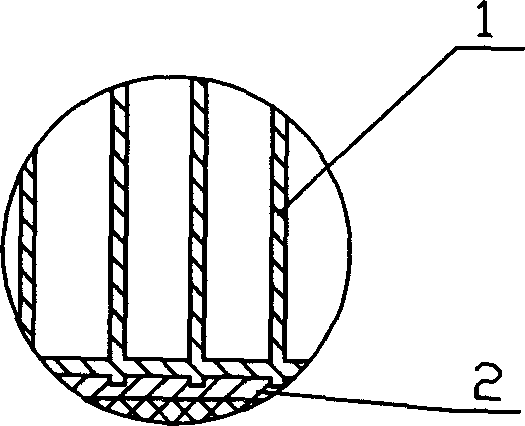

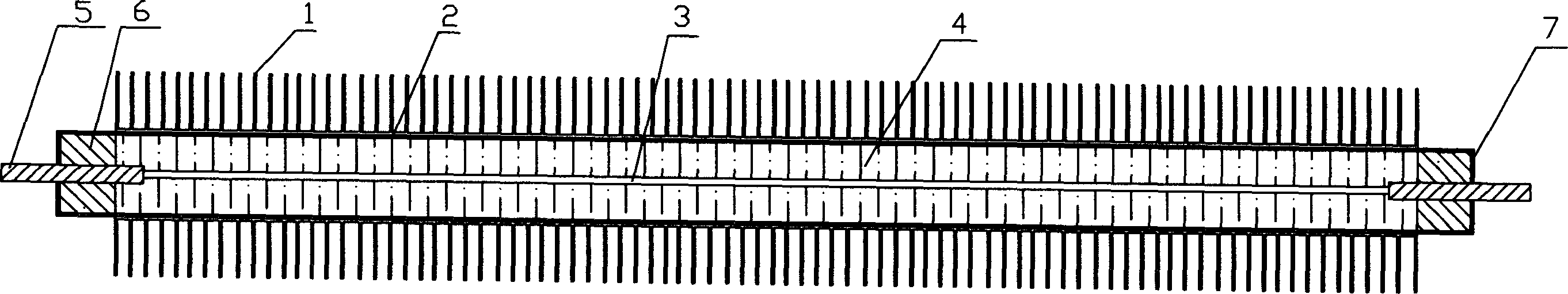

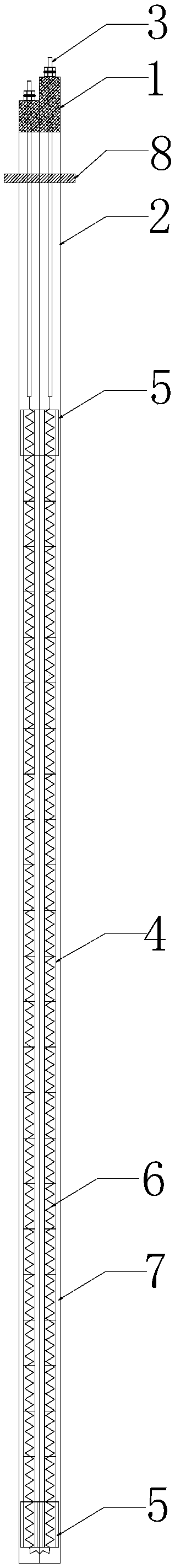

Finned tube heater and its production method

InactiveCN1777341AIncrease surface areaLow surface loadHeating element shapesHeating element materialsEngineeringSealant

The invention relates to a finned-tube heater and production method thereof. A heating body is fitted in the heater housing and a power-supply connection terminal is fitted at the end part of the heater housing, insulation material is filled in the heater housing and insulation sealant is filled at the end port of the heater housing. The characteristic is that the external surface of the heater housing is fitted with finned-tube the lower part of which is buried in the heater housing. Advantages: raised surface area of the heater, low surface load and temperature, reduced heater housing size and raw material and cost and prolonged service life.

Owner:穆壮荣

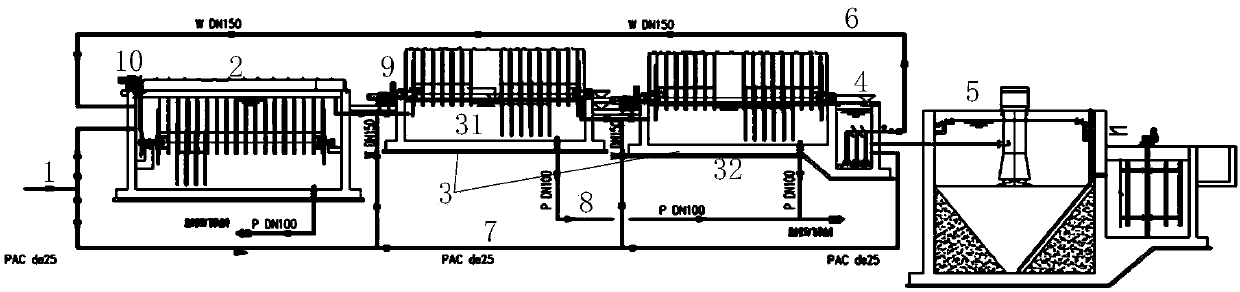

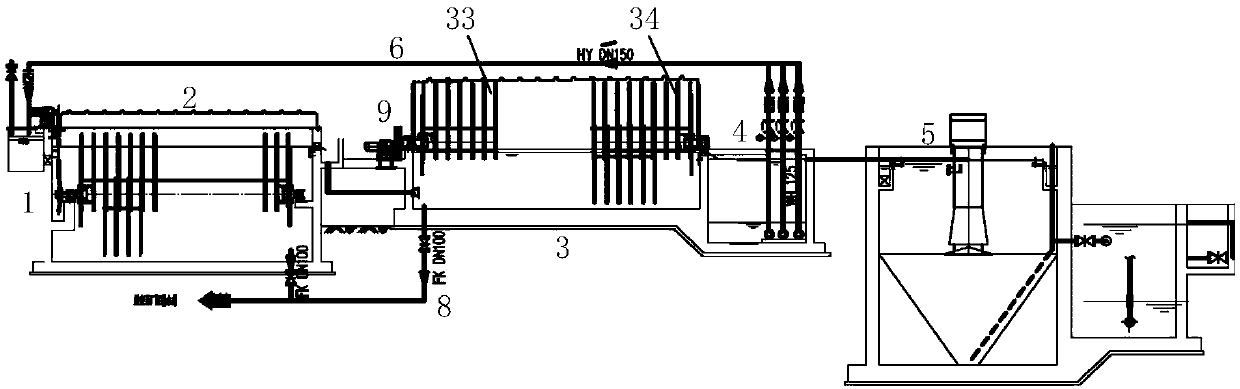

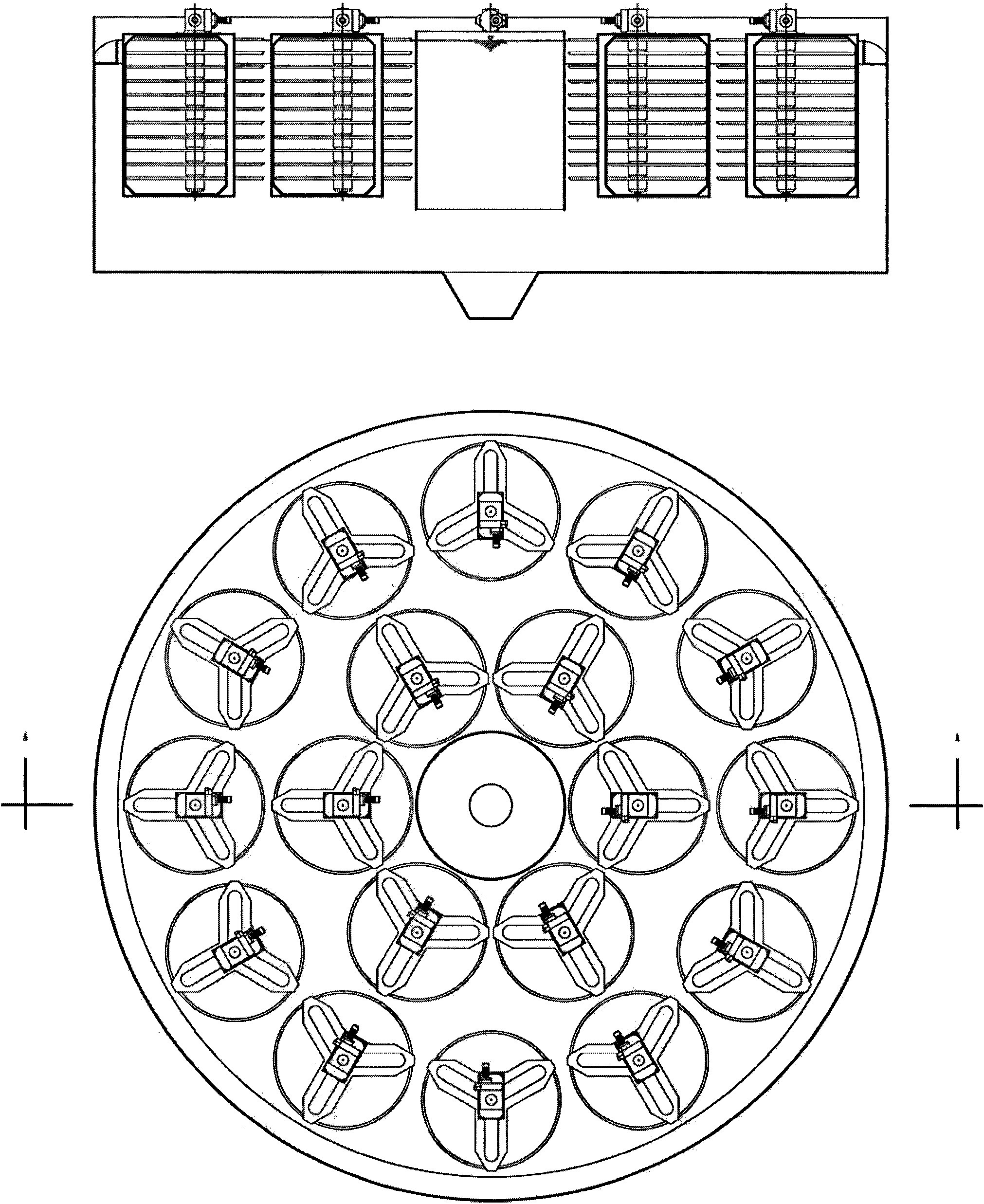

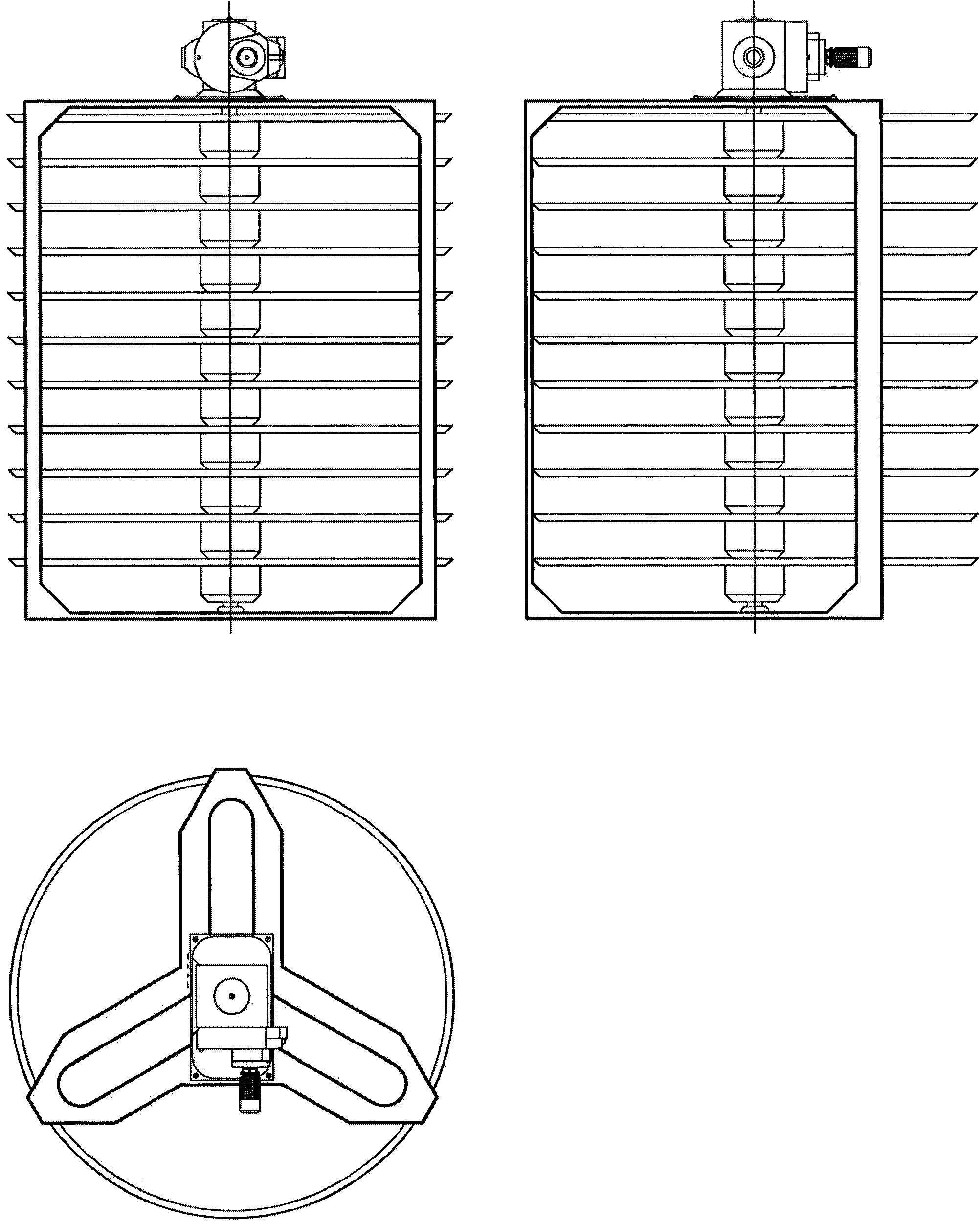

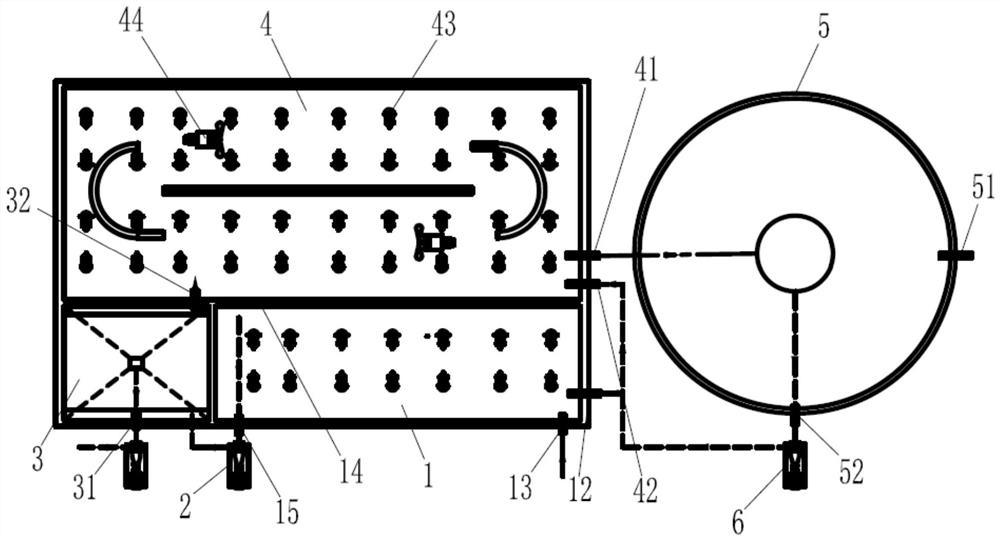

Modularized biological rotating disc multi-serial stage system for deeply treating domestic sewage

InactiveCN109626568AReduce TNIncrease controlWater/sewage treatmentTreatment with aerobic and anaerobic processesRefluxBiological unit

The invention discloses a modularized biological rotating disc multi-serial stage system for deeply treating domestic sewage. According to the components of the modularized biological rotating disc multi-serial stage system, a sewage inlet is formed in a full-immersion biological rotating disc unit; the full-immersion biological rotating disc unit is sequentially connected with a multi-serial stage half-immersion biological rotating disc unit and a settling unit; the disc piece distance of a front-stage biological unit is larger than that of a rear-state biological unit in the multi-serial stage half-immersion biological rotating disc unit; multiple medicine adding points are arranged on a medicine adding unit and located on the full-immersion biological rotating disc unit and multi-serialstage half-immersion biological rotating disc unit respectively; a reflux unit is connected between a tail end water outlet of the half-immersion biological rotating disc unit and a front end sewageinlet of the full-immersion biological rotating disc unit; an up-to-standard water outlet is formed in the settling unit. Through a combined technology, it can be ensured that the COD, ammonia and nitrogen of effluent reach standards, and all indexes of the effluent reach first-level A discharging standards of contaminant discharging standards of municipal wastewater treatment plants (GB189118-2002).

Owner:SOUNDGRP CO LTD +2

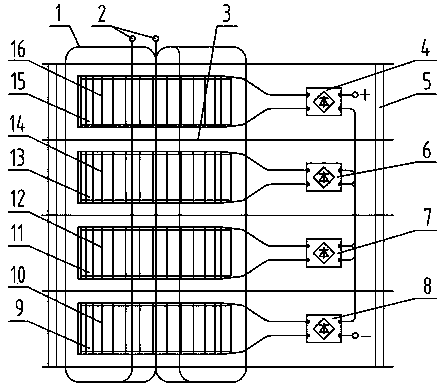

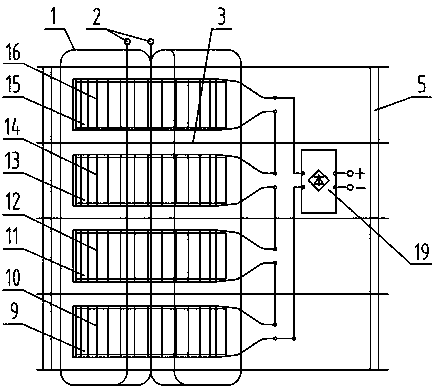

High power, high frequency and high voltage rectifier transformer

ActiveCN103413663AExtended service lifeReduce lossAc-dc conversion without reversalTransformers/inductances coils/windings/connectionsHigh voltage igbtLow voltage

The invention discloses a high power, high frequency and high voltage rectifier transformer. The high power, high frequency and high voltage rectifier transformer comprises at least two iron cores, high voltage winding groups, rectifier bridges, low voltage winding groups and an oil tank and also comprises a supporting frame; the iron cores are arranged on the supporting frame sequentially; gaps are reserved between the adjacent iron cores; the high voltage winding groups which wind the iron cores are connected with the matched rectifier bridges; output of the rectifier bridges is in series connection sequentially and then is output; the low voltage winding groups wind the inside of iron core holes in a penetrating mode; insulating layers are arranged between the high voltage winding groups which wind the adjacent iron cores; insulating layers are arranged between the high voltage winding groups and the low voltage winding groups; the supporting frame is arranged in the oil tank. The high power, high frequency and high voltage rectifier transformer has the advantages of being capable of avoiding high local temperature rise and accordingly reducing the aging speed of materials, extending the service life of transformer oil and meanwhile extending the service life of the transformer.

Owner:YANCHENG ZHENGBANG ENVIRONMENTAL PROTECTION TECH

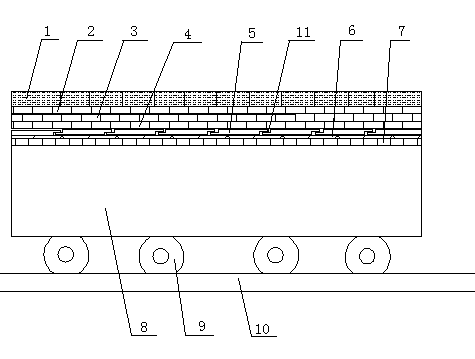

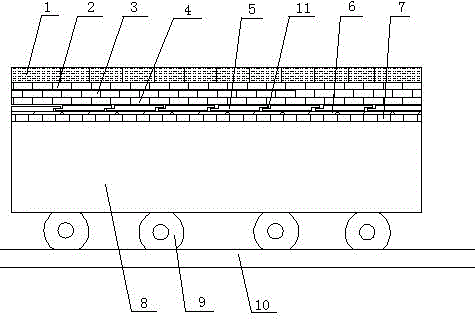

Bogie hearth for bogie hearth type resistance furnace

The invention provides a bogie hearth for a bogie hearth type resistance furnace. The bogie hearth for the bogie hearth type resistance furnace is formed by cast iron which is used for bearing workpieces, a fire-proof layer, a first thermal insulation layer, a second thermal insulation layer, a base plate layer, a heating element, a thermal preservation brick and a bogie hearth body which are arranged from top to bottom sequentially; the base plate layer is formed by a plurality of strip-shaped furnace bottom plates in a splicing mode; the furnace bottom plates are made of heat resisting steel; splicing positions of the adjacent furnace bottom plates are in hasp modes; splicing positions of the furnace bottom plates are provided with thermal expanded and cold contracted gaps; the heating element is bent to be in a wave band shape through belts; the heating element is fixed on the thermal preservation brick. The bogie hearth for the bogie hearth type resistance furnace has the advantages of guaranteeing the furnace bottom temperature; improving the surficial area of the heating element, reducing the surface load of the heating element and prolonging the service life of the heating element due to the fact that the heating element is arranged on bogie hearth; meanwhile avoiding short circuit due to the fact that oxidized iron sheets fall on the heating element and improving the production safety due to the furnace bottom plates.

Owner:徐州东创重工机械有限公司

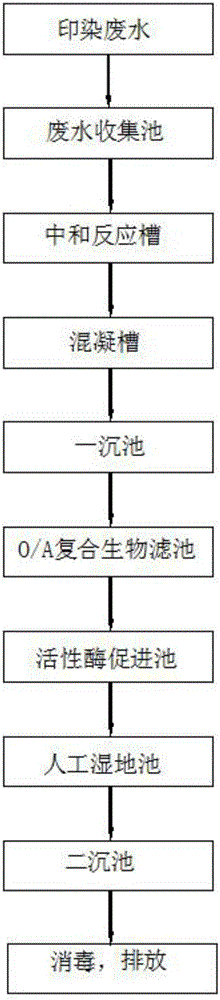

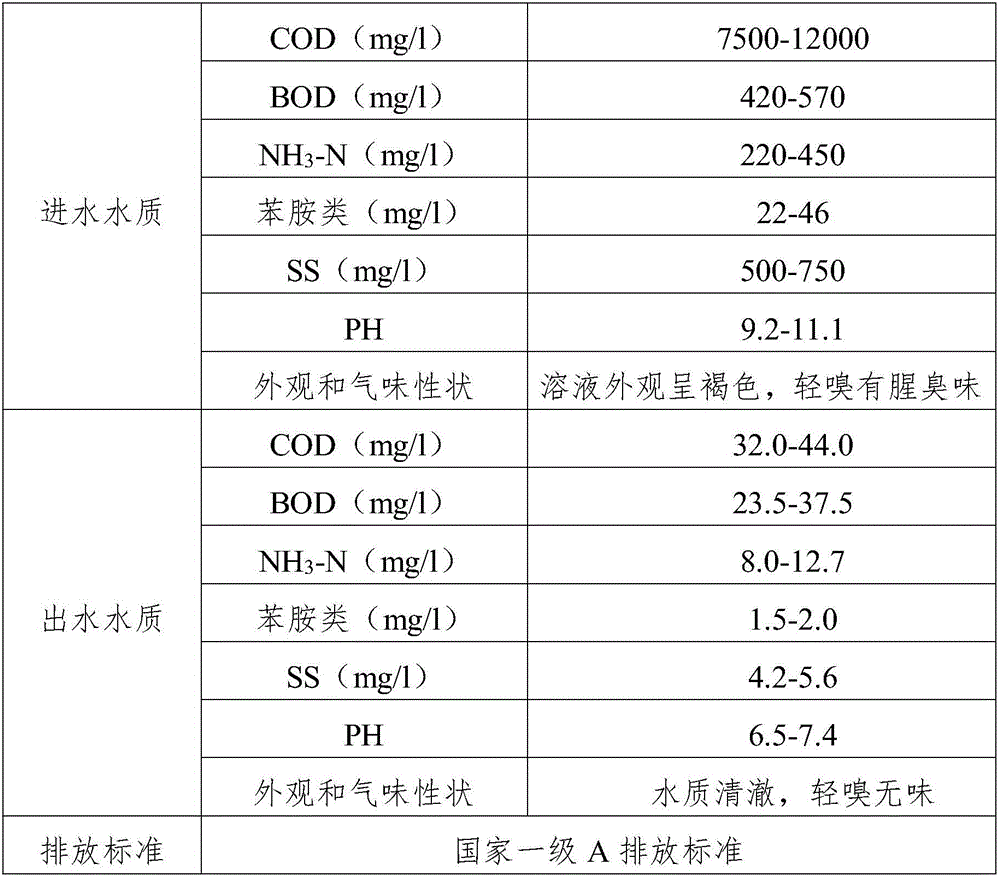

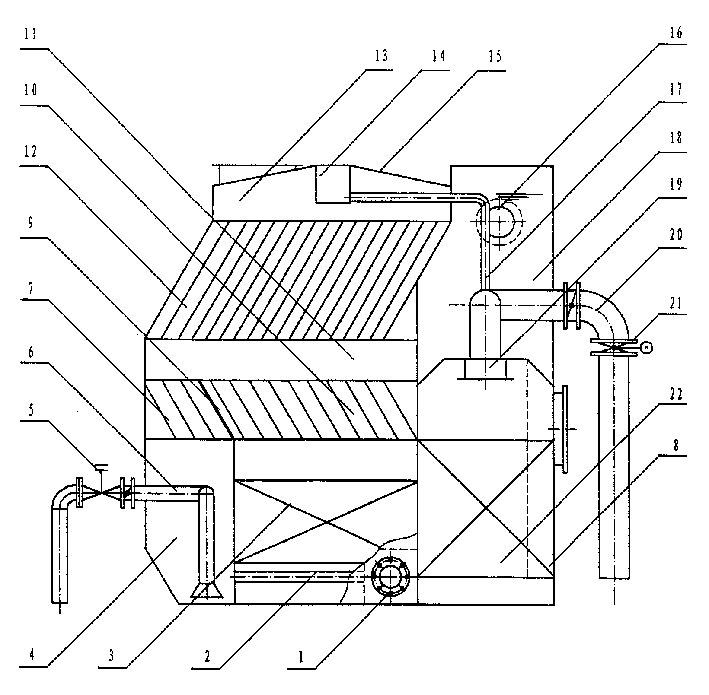

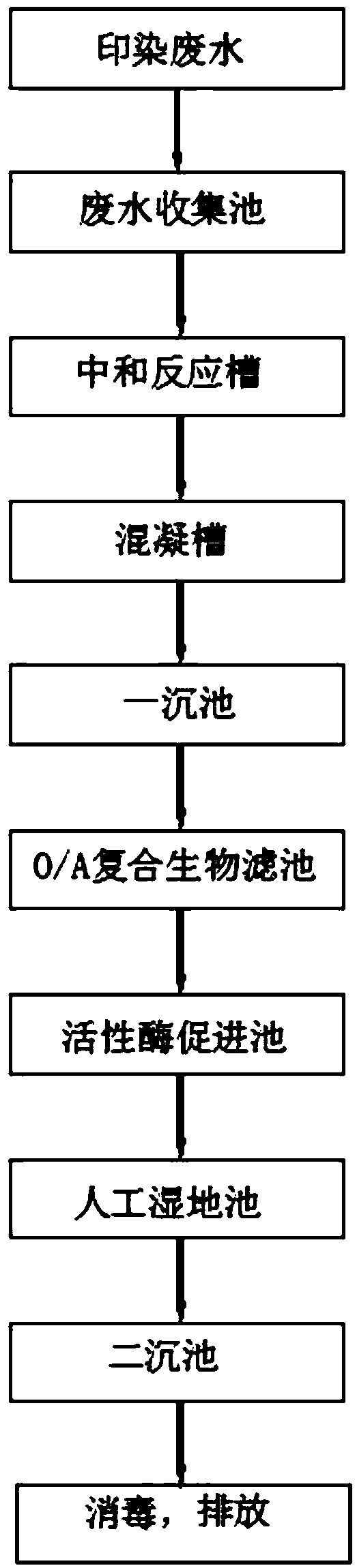

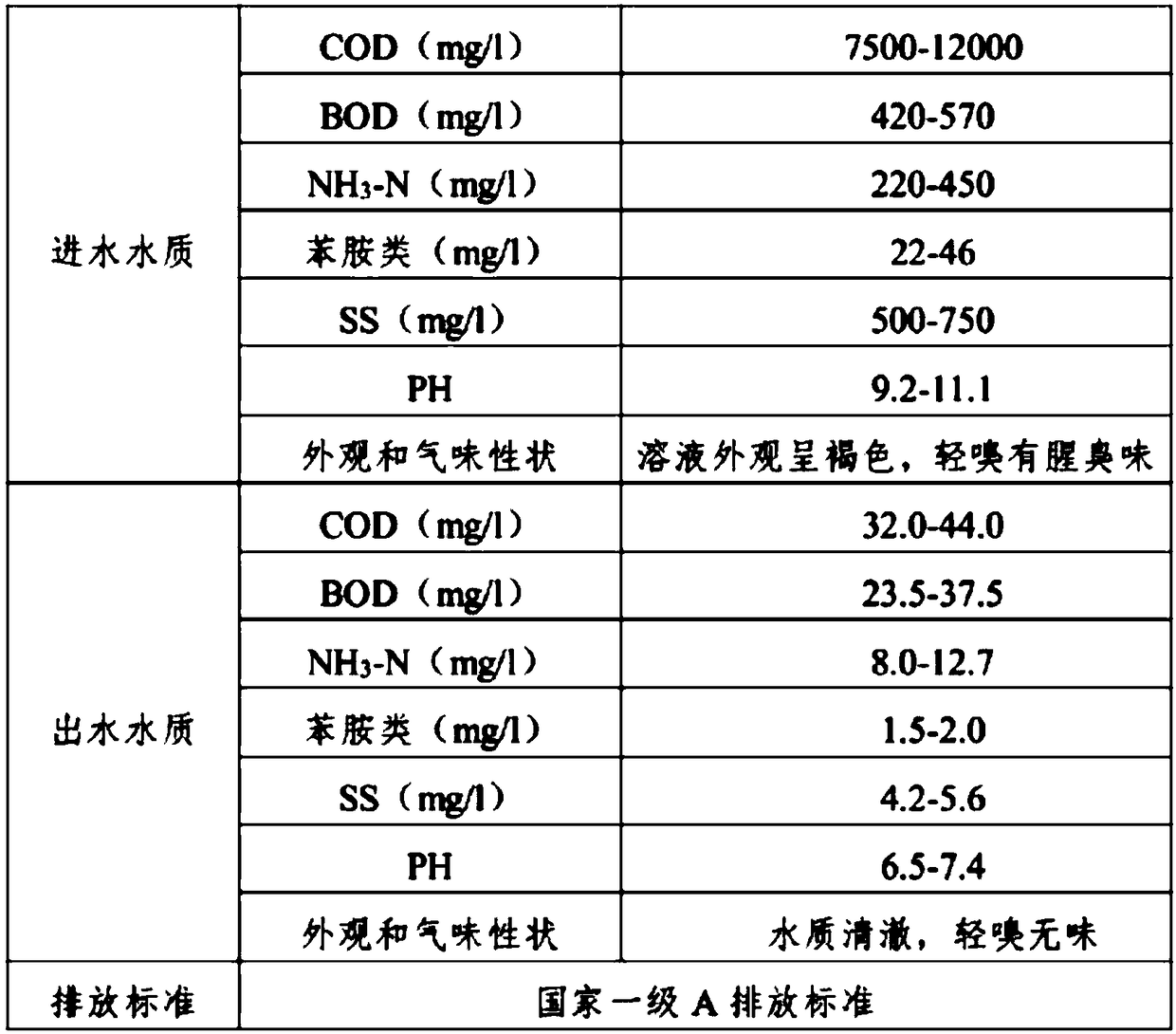

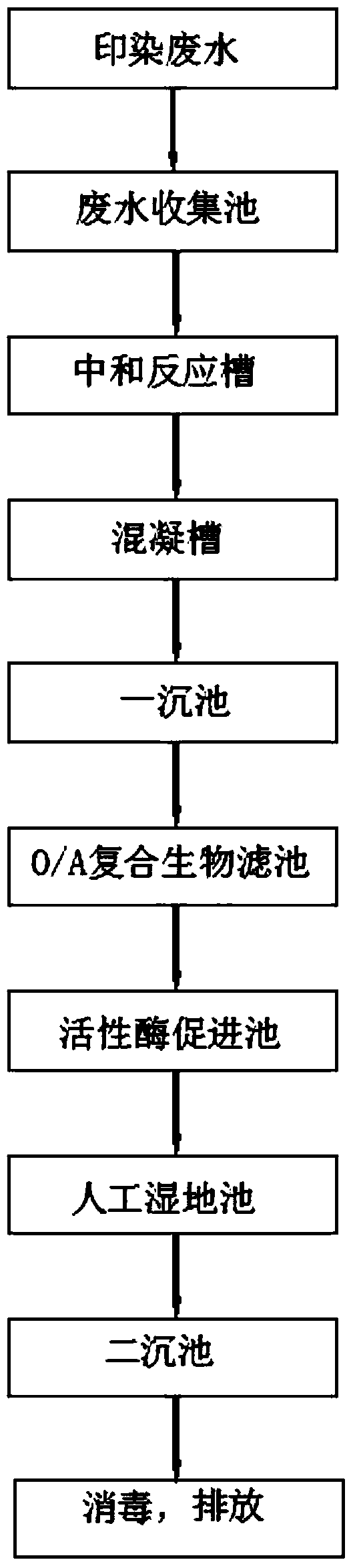

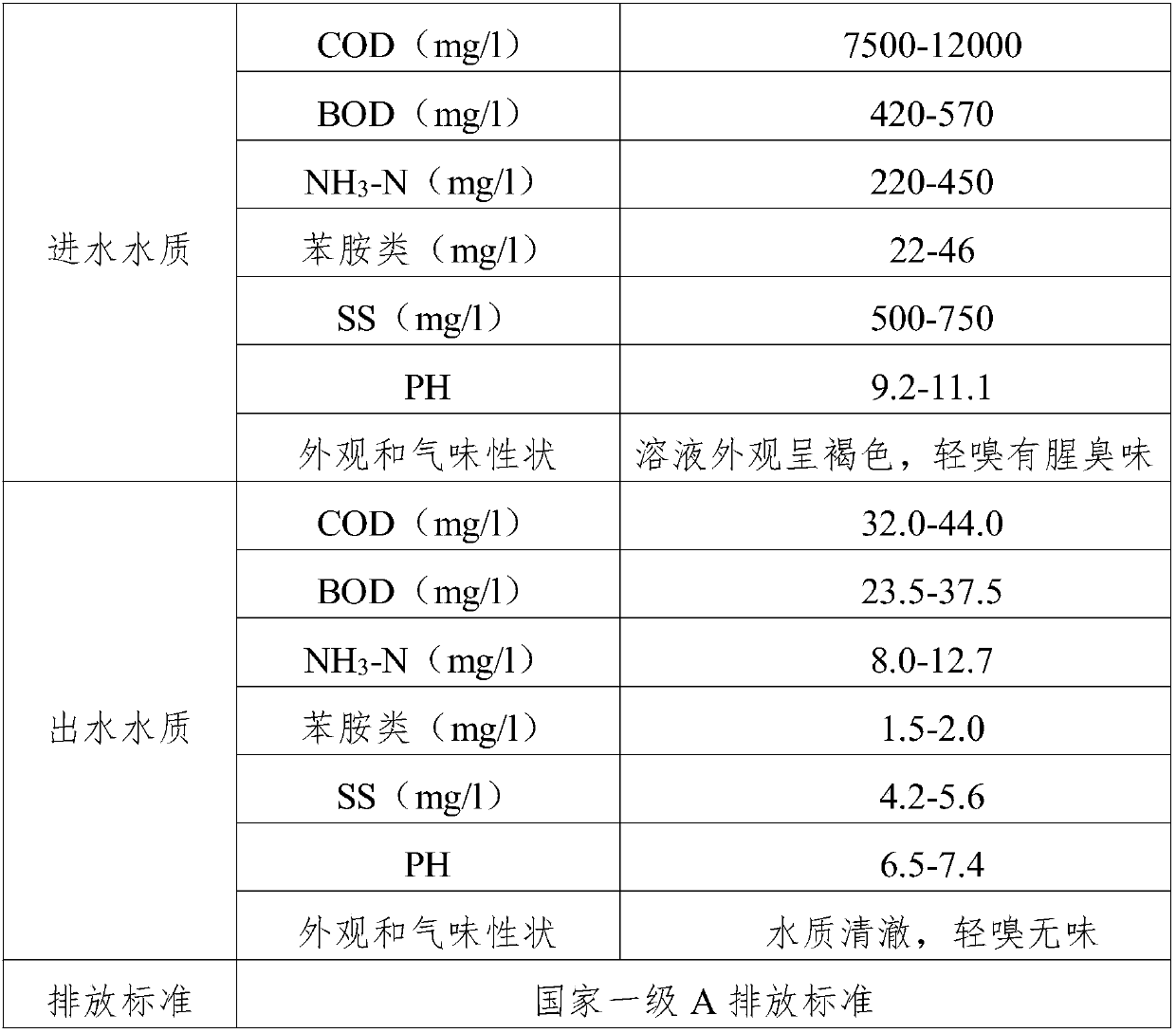

Combined process for treating textile printing and dyeing wastewater

ActiveCN105967453AReduce COD contentLow chroma valueSpecific water treatment objectivesTreatment involving filtrationTextile printerConstructed wetland

The invention relates to the technical field of treatment of textile printing and dyeing wastewater, in particular to a combined process for treating textile printing and dyeing wastewater, comprising the steps such as neutralizing, coagulating and precipitating, filtering with an O / A combined biofilter, activating with an active enzyme promoter, adsorbing with a constructed wetland tank, precipitating, sterilizing, and discharging; the combined process provided by the invention has good wastewater purifying effect and enables continuous treatment of batch production wastewater.

Owner:ANHUI GUONENG YISHENG ENVIRONMENTAL PROTECTION SCI & TECH

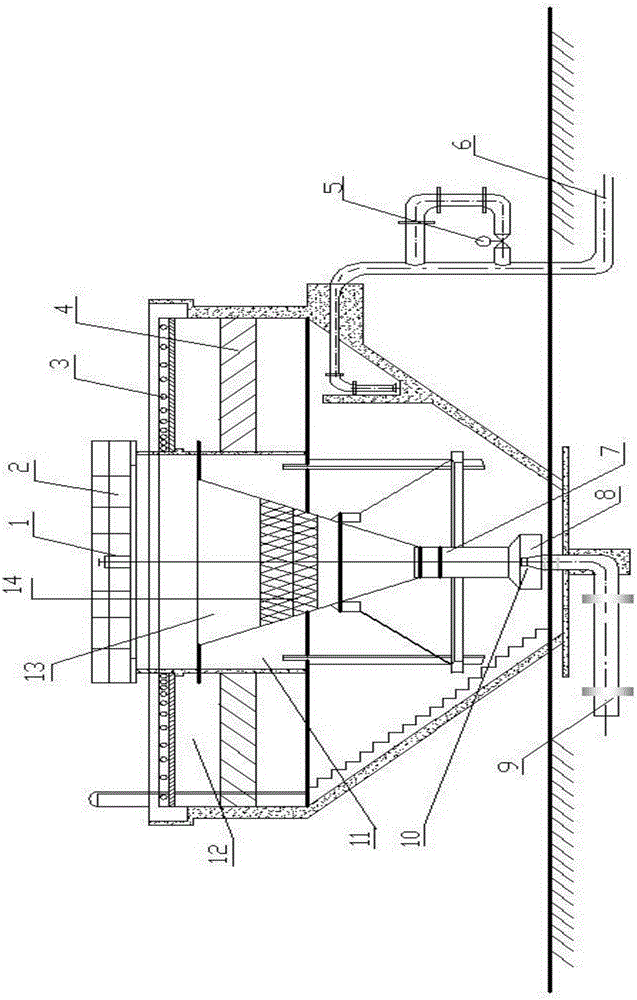

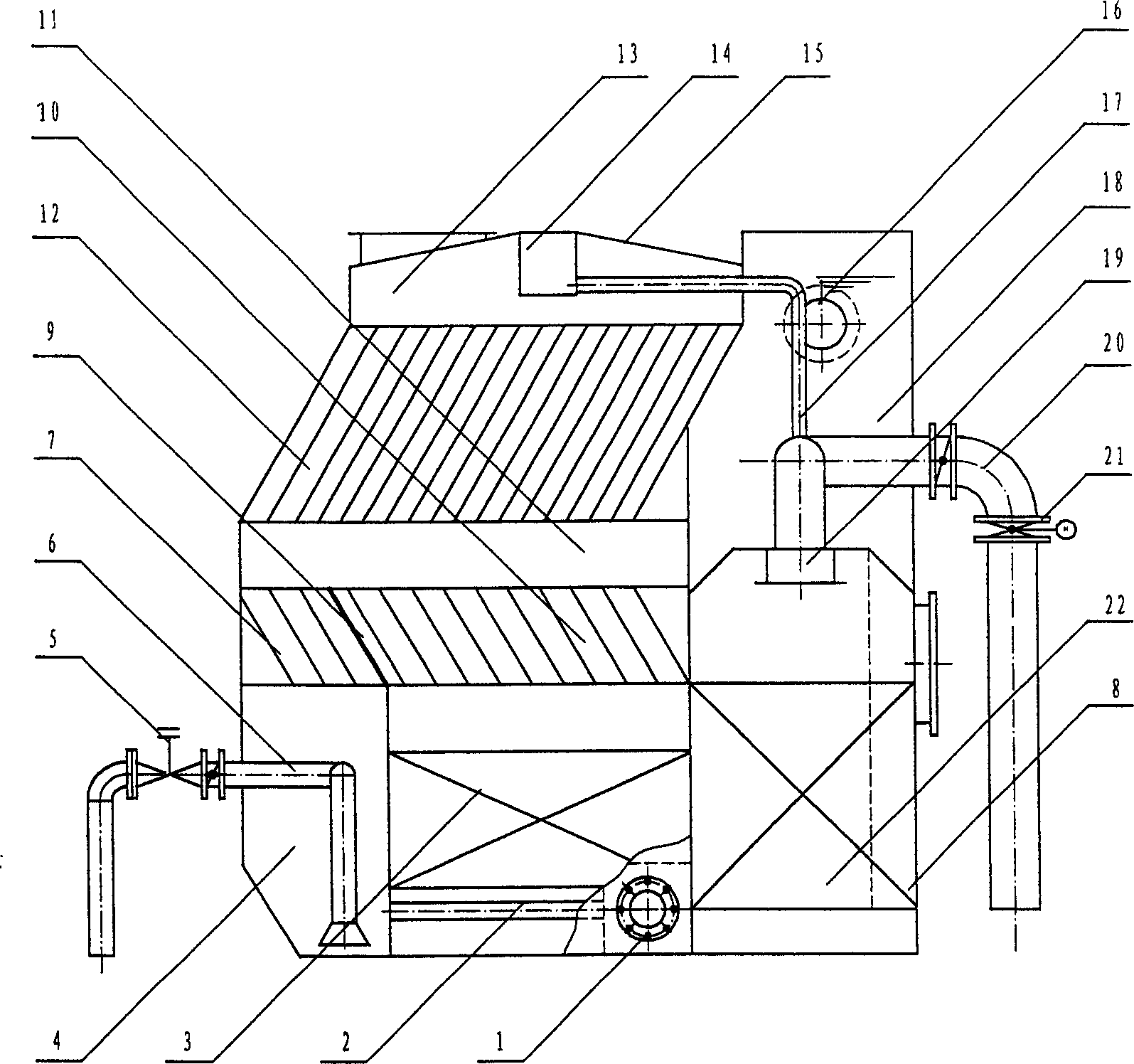

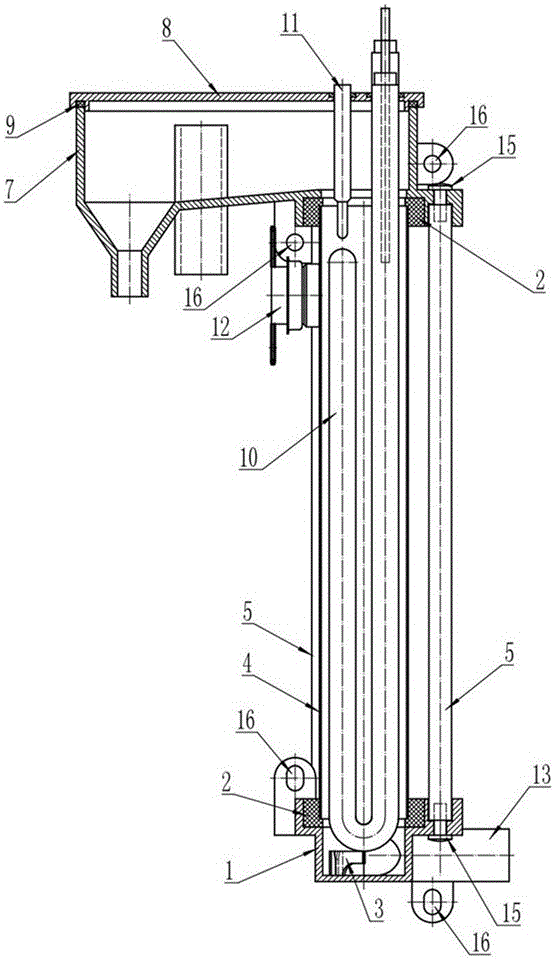

Efficient hydraulic circulation clarifier

PendingCN106277255AConstant flow rateHigh trafficWater/sewage treatment by flocculation/precipitationWater/sewage treatment apparatusFlocculationWater volume

The invention discloses an efficient hydraulic circulation clarifier and aims to provide a circulation clarifier which is high in operation stability, reduces chemical and energy consumption, can better adapt to changes of water volume and water quality during actual operation and reduces operation cost of water treatment facilities. The efficient hydraulic circulation clarifier adopts a method implemented according to the following steps: firstly, raw water enters a water inlet pipe at the clarifier bottom, is sprayed into a Venturi tube at a high speed through a spray nozzle and a horn mouth, so that vacuum is formed near the horn mouth in the lower part of the Venturi tube and sucks a large amount of backflow sludge, the backflow sludge and the raw water mix and react fiercely in the Venturi tube, and then a product enters a first flocculation basin and a second flocculation basin; a sludge and raw material mixed solution overflowing from the second flocculation basin is subjected to sludge-water separation in a separation chamber in a settling region, clear water moves upwards and is collected by a water collection tank and drained outward, one part of the settled sludge enters an automatic sludge discharge pipe, and the other part of the settle sludge is sucked by the Venturi tube, enters a reaction system and is recycled continuously.

Owner:ANHUI UNIV OF SCI & TECH

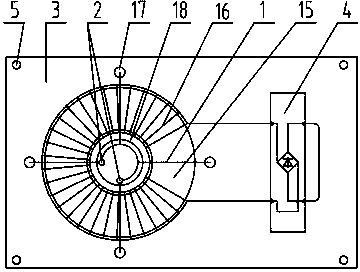

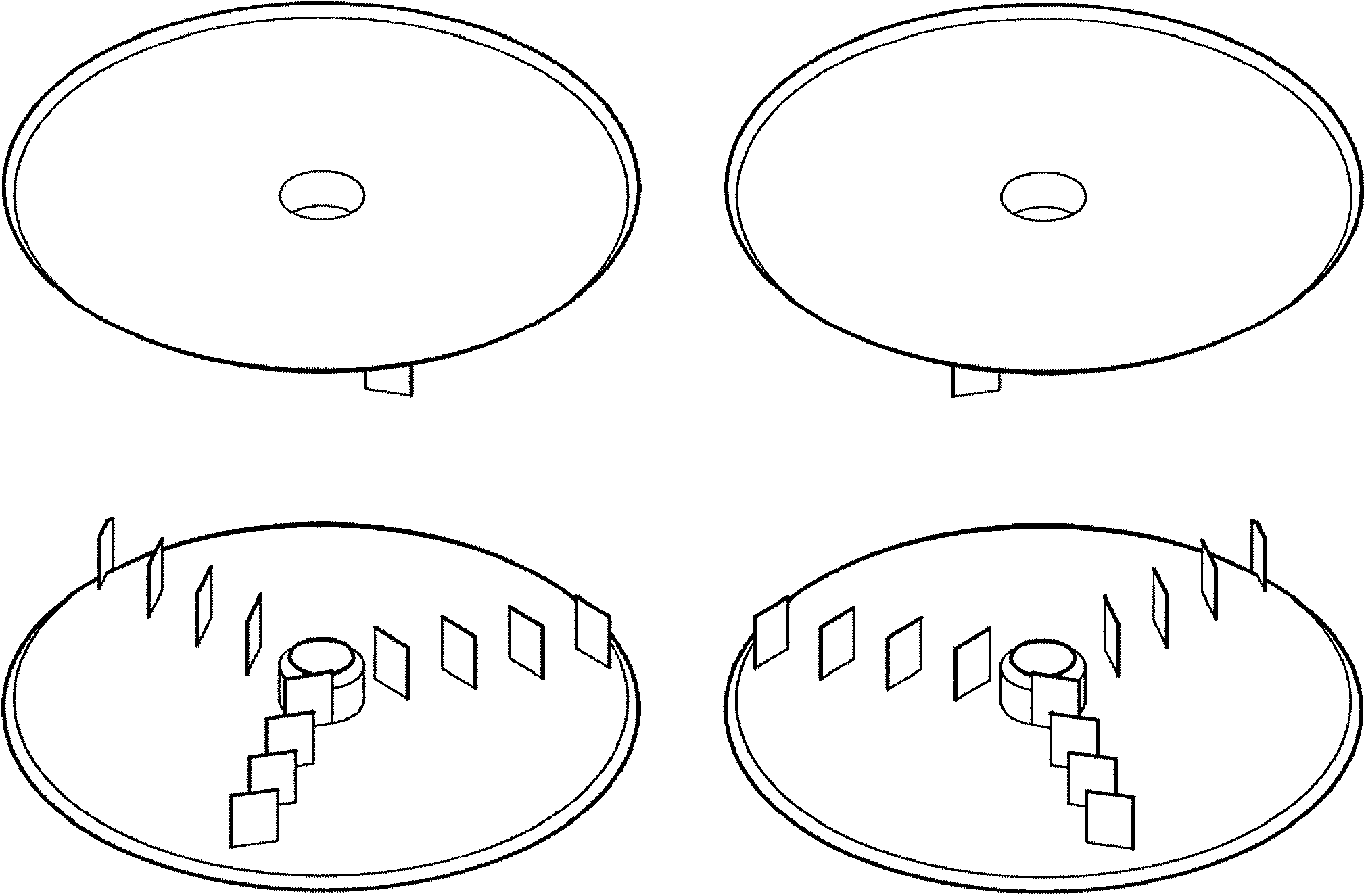

Improved multi-layer flat unit combined settling pond process

ActiveCN103845927ASimple mechanical structureHigh working reliabilitySedimentation settling tanksHigh concentrationActivated sludge

The invention relates to an improved multi-layer flat unit combined settling pond process which specially aims at urban sewage treatment and also can be used for feed water treatment and industrial wastewater treatment. The process has the most obvious characteristics that a circular settling flat plate and scrapers (scrapers on odd and even layers are different) are integrated into turntables, multiple turntables are overlapped to form units, the scrapers on the odd layers rotate (as being arranged on a central transmission shaft), the scrapers on the even layers are static (as being fixed on a frame of the units), and the settling and scraping functions are realized. The multiple units are arranged in a clarification area of the settling pond, and a settling pond mud scraper is additionally arranged in a concentration area on the lower part of the settling pond. The process has the beneficial effects that a mechanical structure of the multilayer flat unit is simplified, the operating stability is improved, the distance between the flat plates is shortened, and the number of the flat plates is increased, so that the total settling area of the settling pond is increased, the surface hydraulic loading is reduced, high-concentration activated sludge in the system is maintained, and the floor space of the settling pond is obviously saved. Moreover, the turntables can be molded at a time, and the cost is reduced.

Owner:三亚易可霖环保科技有限公司

Method for aerobic synchronous nitration and denitrification of coking wastewater

InactiveCN101468852AIncrease in sizeLarge particle sizeTreatment with aerobic and anaerobic processesComing outSludge

The invention discloses a method for treating coked wastewater through aerobic and synchronous nitrification and denitrification. Firstly, through culture of nitrobacteria, water comes out from an aerobic pool; NH3-N is less than 1 mg / l; secondly, the volume of sludge is improved so as to increase the volume of sludge of the aerobic pool to 50 to 80 percent; and finally the concentration of dissolved oxygen is reduced; and the concentration of the dissolved oxygen of the aerobic pool is reduced from 3 to 6 mg / l to 1 to 3 mg / l. Mass experiment results show that by a method of reducing the concentration of the dissolved oxygen and improving the volume of the sludge of the aerobic pool, the sludge surface has nitrification reaction in an aerobic state; as the inside of the sludge has thicker floccule, the dissolved oxygen can not penetrate to the inside of the sludge, and the sludge is in an anaerobic state to form denitrification reaction; the removing rate of ammonia nitrogen reaches over 95 percent; the removing rate of total nitrogen reaches 70 percent around; and the method reduces investment, reduces energy consumption and keeps the stable quality of outlet water.

Owner:ANYANG IRON & STEEL

Environment-friendly near dry cutting liquid and preparation method thereof

The invention relates to the technical field of near dry cutting liquid, and specifically relates to an environment-friendly near dry cutting liquid and a preparation method thereof. The environment-friendly near dry cutting liquid is characterized by being prepared from the following raw materials in percentage by weight: 20-40% of dialkyl thiophosphate, 20-40% of carbaminate, 20-40% of poly alkylene glycol, 2-5% of carboxamide, 1-2% of sodium benzoate, 1-2% of hydantoin and 15-35% of deionized water. Compared by the prior art, the environment-friendly near dry cutting liquid provided by theinvention has the advantages of very good lubricity and extreme pressure and anti-wear performance, and high-end requirements of a metal processing technique can be satisfied by using a very little amount of cutting liquids; and the dosage of the lubricant can be reduced to be below 10% of that of the traditional lubricant by matching with a near dry cutting device, and thus, the harms to the environment and workers are reduced.

Owner:常州海纳环保科技有限公司

Method for aerobic synchronous nitration and denitrification of coking wastewater

InactiveCN101468852BIncrease in sizeReduce power consumptionTreatment with aerobic and anaerobic processesAmmoniacal nitrogenSludge

The invention discloses a method for treating coked wastewater through aerobic and synchronous nitrification and denitrification. Firstly, through culture of nitrobacteria, water comes out from an aerobic pool; NH3-N is less than 1 mg / l; secondly, the volume of sludge is improved so as to increase the volume of sludge of the aerobic pool to 50 to 80 percent; and finally the concentration of dissolved oxygen is reduced; and the concentration of the dissolved oxygen of the aerobic pool is reduced from 3 to 6 mg / l to 1 to 3 mg / l. Mass experiment results show that by a method of reducing the concentration of the dissolved oxygen and improving the volume of the sludge of the aerobic pool, the sludge surface has nitrification reaction in an aerobic state; as the inside of the sludge has thickerfloccule, the dissolved oxygen can not penetrate to the inside of the sludge, and the sludge is in an anaerobic state to form denitrification reaction; the removing rate of ammonia nitrogen reaches over 95 percent; the removing rate of total nitrogen reaches 70 percent around; and the method reduces investment, reduces energy consumption and keeps the stable quality of outlet water.

Owner:ANYANG IRON & STEEL

Highly effective integral water purifying device

InactiveCN1481921AAvoid short flowSlipped in timeMultistage water/sewage treatmentFiltration circuitsSludgeIndustrial water

The efficient integral water purifying apparatus includes reaction area, precipitation area, filtering area, clear water area, sludge exhausting pipe, reverse rinse pipe, electric controller and completed closed pressure-bearing body. The water inlet pipe is connected to the reaction area via water distributing pipe, and there are also sludge area and filtering area on two sides of the reaction area separately, inclined-pipe diversion area over the reaction area, inclined-pipe sludge collecting area over the sludge area and separated from the inclined-pipe diversion area with partition board, sludge separating area, etc. Owing to the completed closed pressure-bearing structure, the water purifying apparatus is compact, small, efficient, low in cost and suitable for purification of industrial water and domestic water.

Owner:宜兴市自动化水工业设备厂

Complex type treatment process of textile printing and dyeing waste water

InactiveCN108658365APromote degradationReduced waste water surface loadingSpecific water treatment objectivesMultistage water/sewage treatmentComplex typeWaste treatment

The invention relates to the technical field of textile printing and dyeing waste water treatment and specifically relates to a complex type treatment process of textile printing and dyeing waste water. The process comprises the following steps: neutralizing, coagulating, precipitating, filtering in an O / A complex biological filter tank, activating in an active enzymatic tank, adsorption by introducing waste water into a constructed wetland pool, precipitating, disinfecting, discharging and the like. The complex type treatment process of textile printing and dyeing waste water provided by theinvention has good waste water purification effects and can continuously treat a large amount of production waste water.

Owner:望江硕丰汇锦科技有限公司

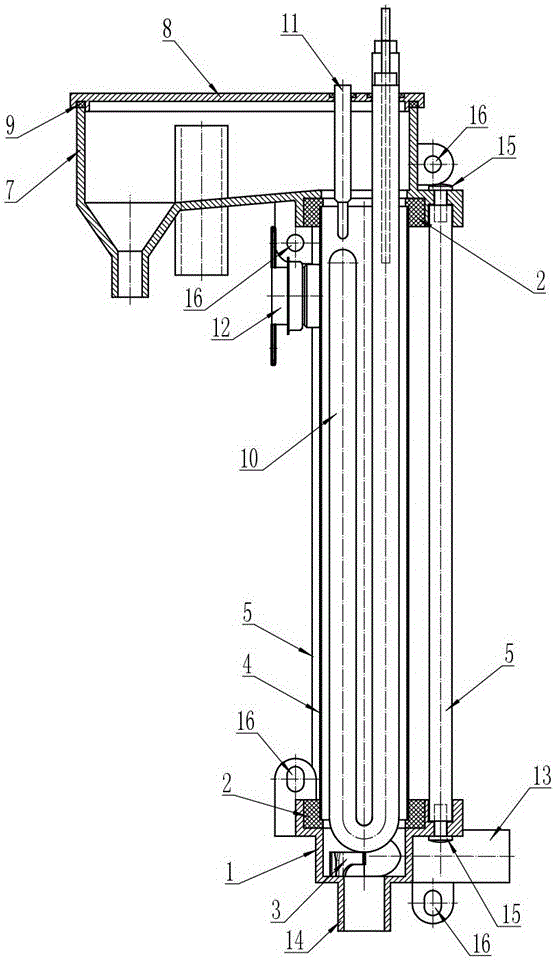

Boiled water heater

InactiveCN105125081AComplete structureSimple structureBeverage vesselsTemperature controlWater volume

The invention provides a boiled water heater. The boiled water heater comprises a water inlet 1, silicon rubber rings 2, a positioning plate 3, a stainless steel tube 4, connecting rods 5, temperature control installation blocks 6, a water outlet 7, a water outlet cover 8, seal rings 9, an electric heating tube 10, a temperature sensor 11 and a dry boiling preventing temperature controller 12, wherein the water inlet 1 and the water outlet 7 are connected by three connecting rods 5; the electric heating tube 10 has a double U shaped structure; the spread length of a heat emitting part of the electric heating tube is more than three times the length of the stainless steel tube 4; and the inner diameter of the stainless steel tube 4 is not more than 24mm. The boiled water heater has a complete structure, low electric heating tube surface load and small water volume, can achieve quicker boiled water outflow, is simple in assembly process, is safe and reliable, has stable properties and long service life and is an ideal instantaneous boiled water heater.

Owner:周冠明

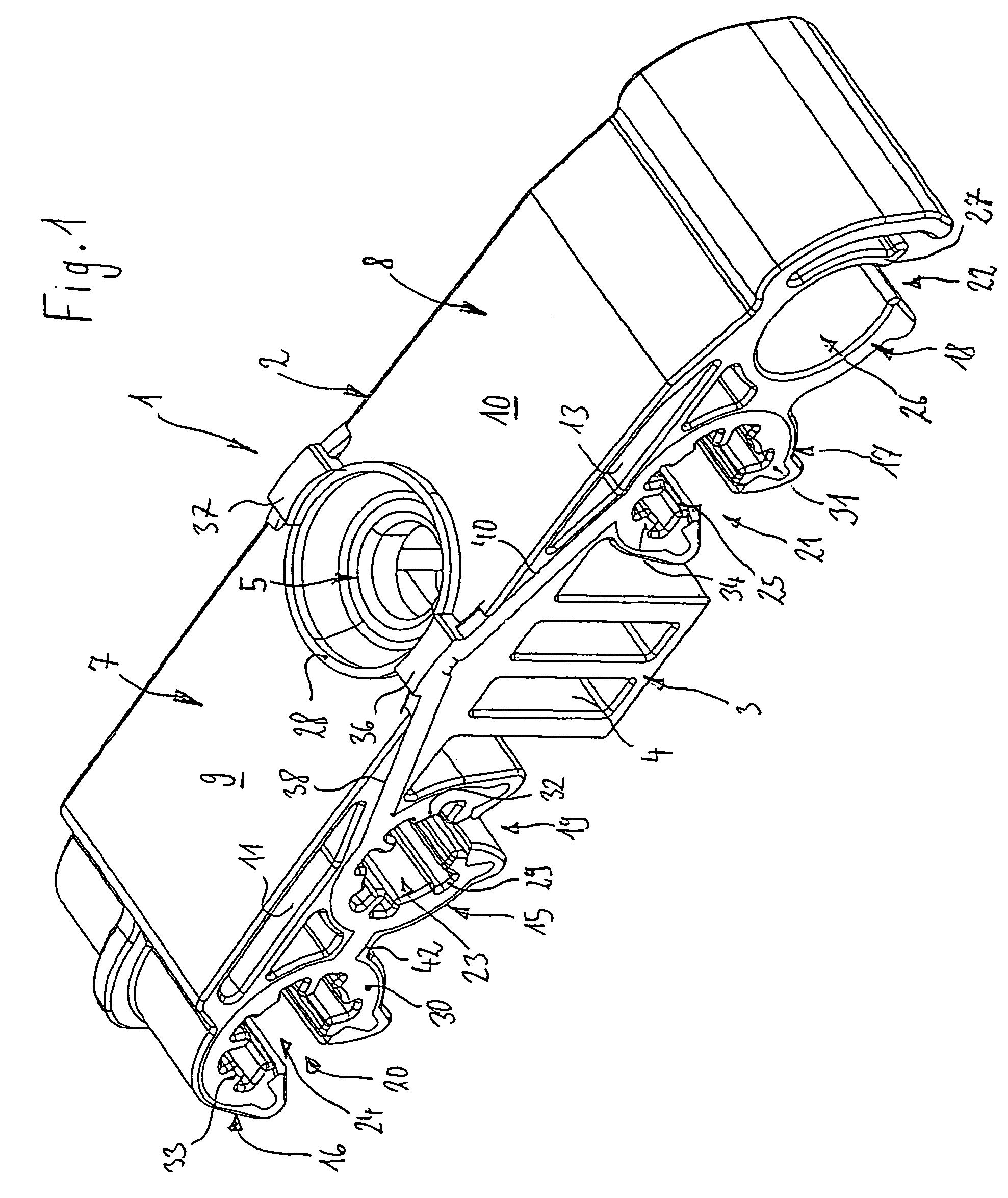

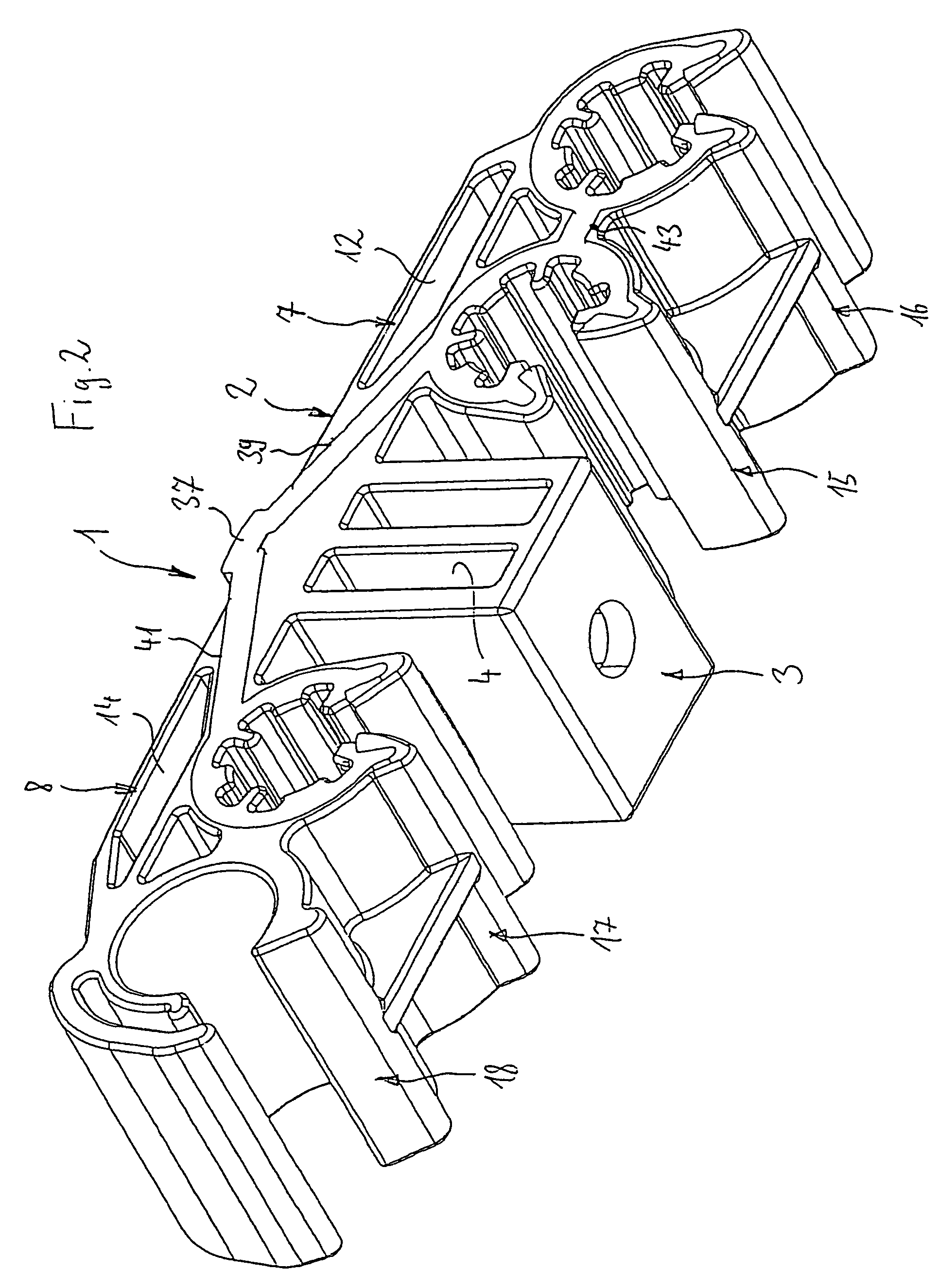

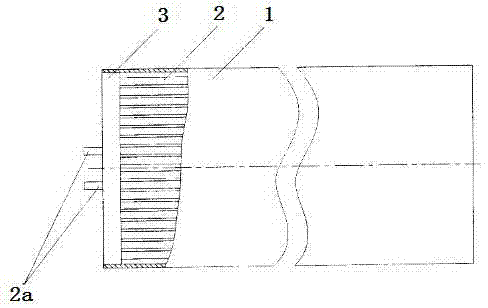

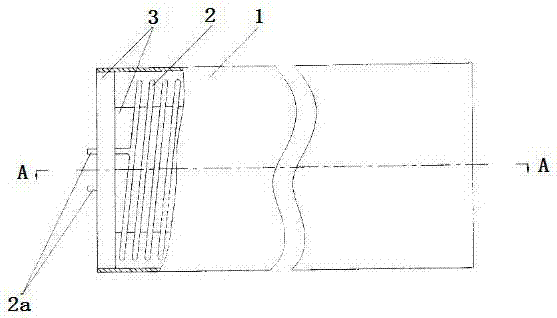

Filter element

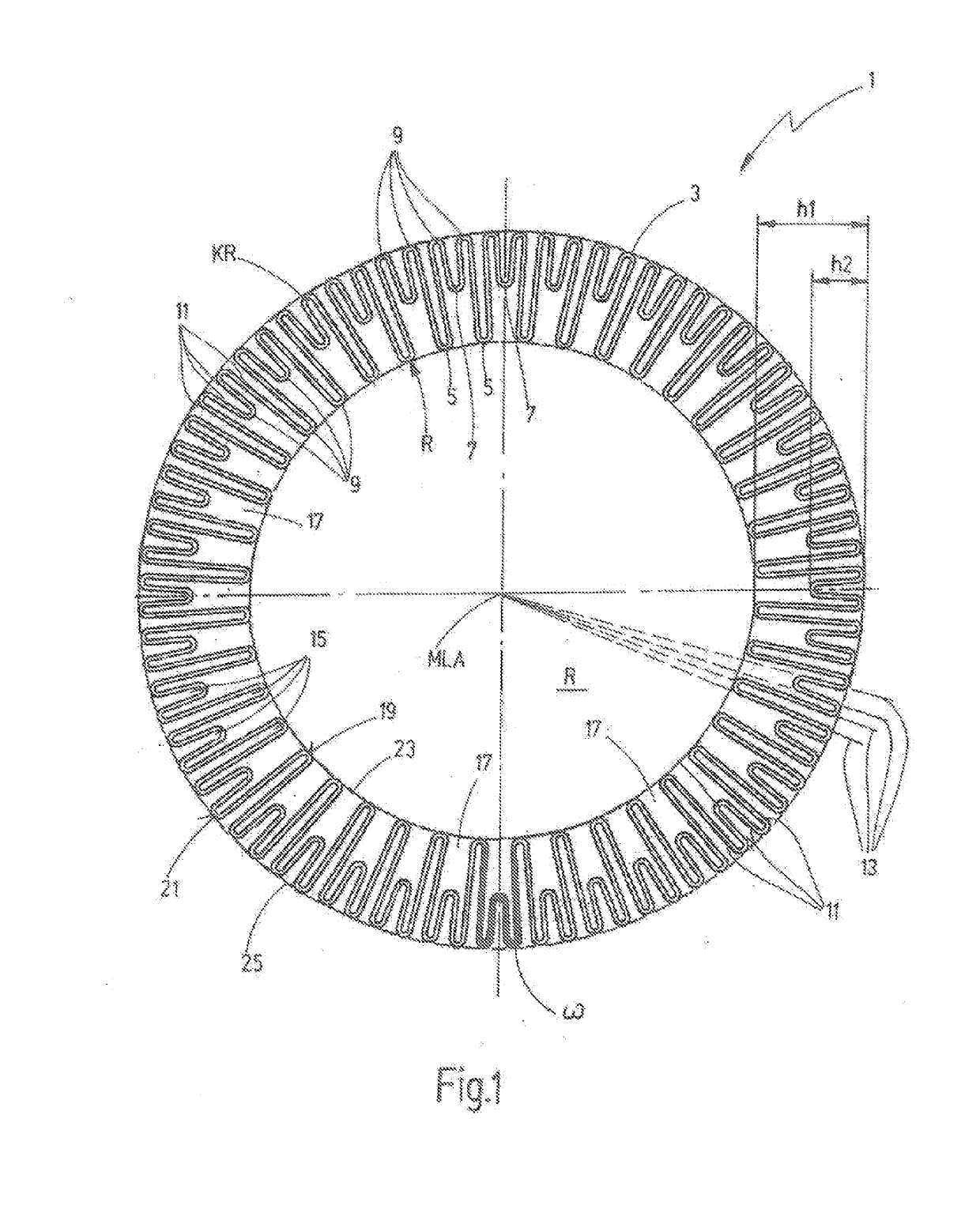

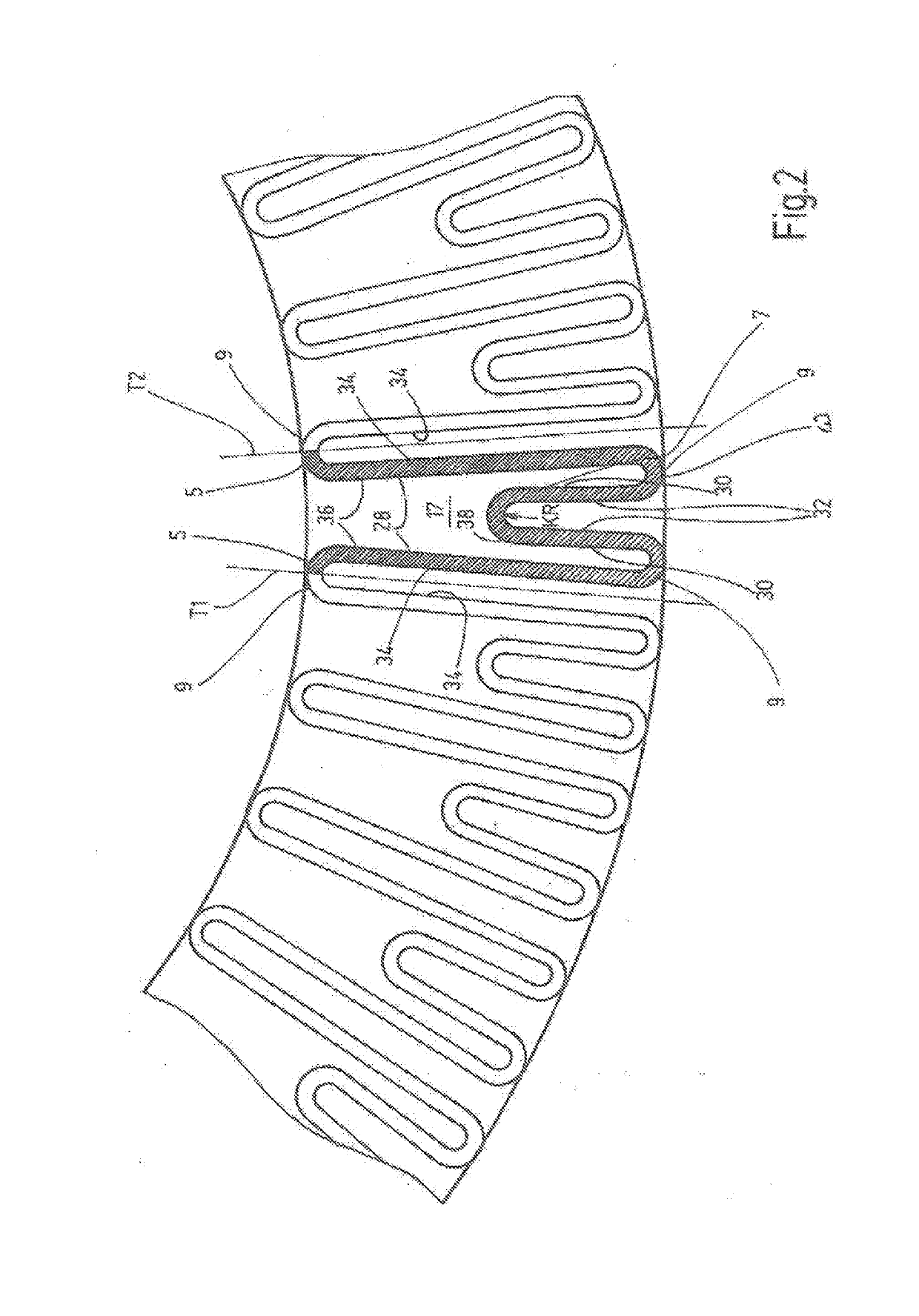

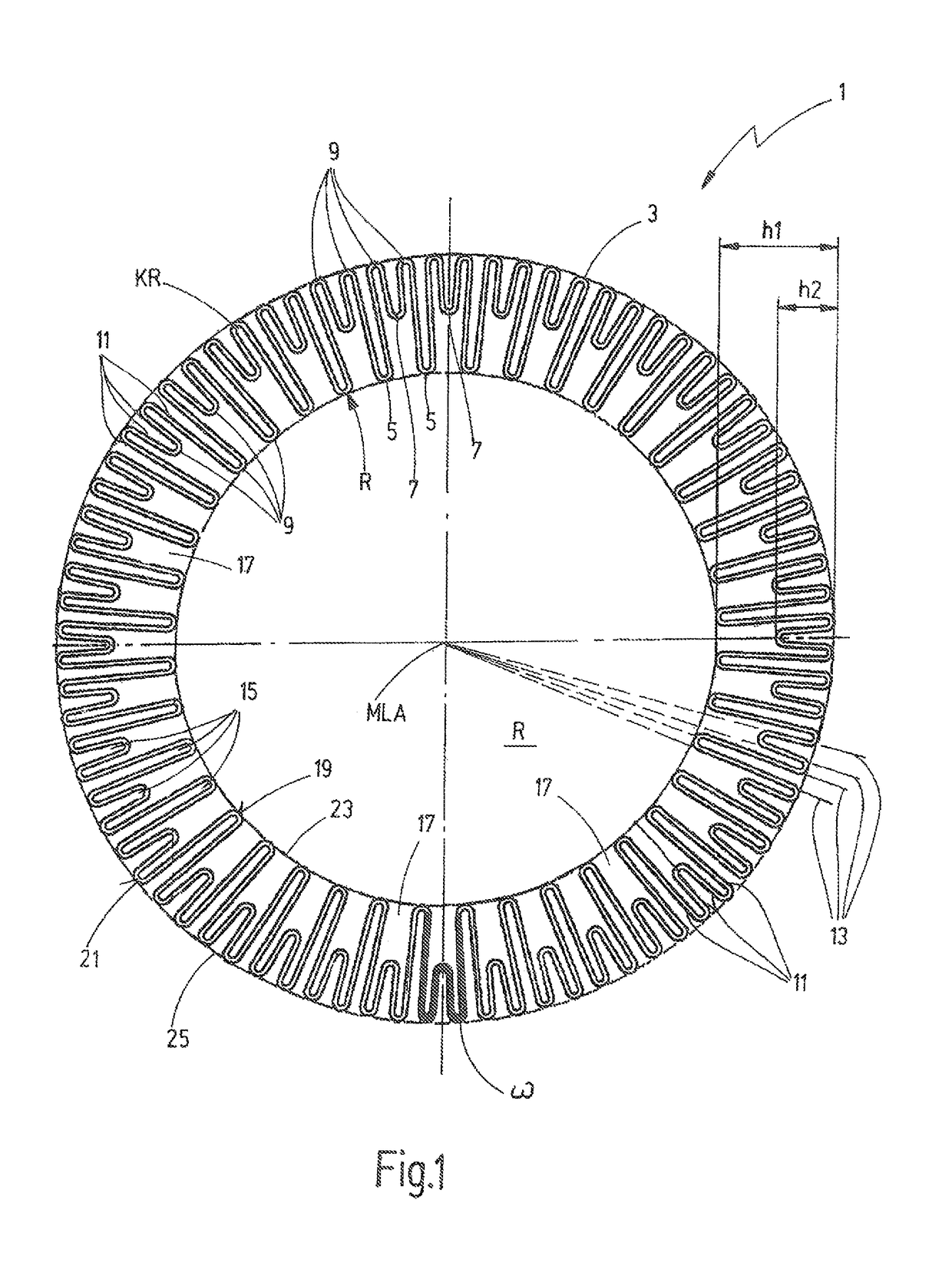

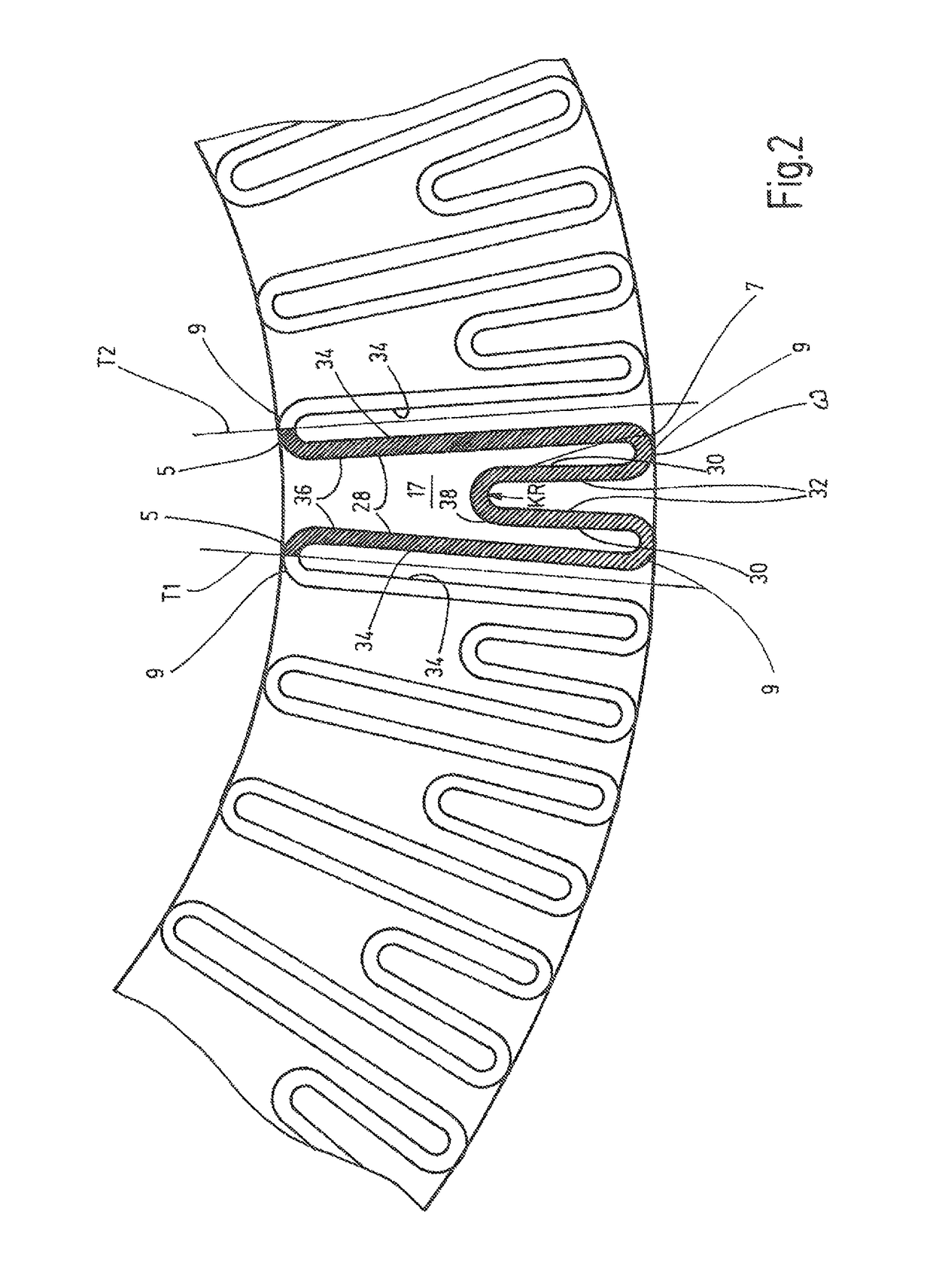

ActiveUS20190143250A1Cost-effectiveMinimize dangerMembrane filtersStationary filtering element filtersFilter mediaHydraulic circuit

A filter element has a preferably multilayer structure of a pleated filter medium (3) with a plurality of individual filter pleats (5, 7). Due to an alternating sequence of filter pleats (5) with a first pleat height (h1) and filter pleats (7) with a second pleat height (h2), more effective filter surfaces are available than with filter pleats with a uniform pleat height. Upon throughflow by a fluid to be filtered, a lower surface load for the filter medium (30 and lower passage speed of the fluid are present during filtration. A static loading of the filter medium (3) during operation of the filter is then reduced. A hydraulic circuit has such a filter element (1).

Owner:FILTERTECHN

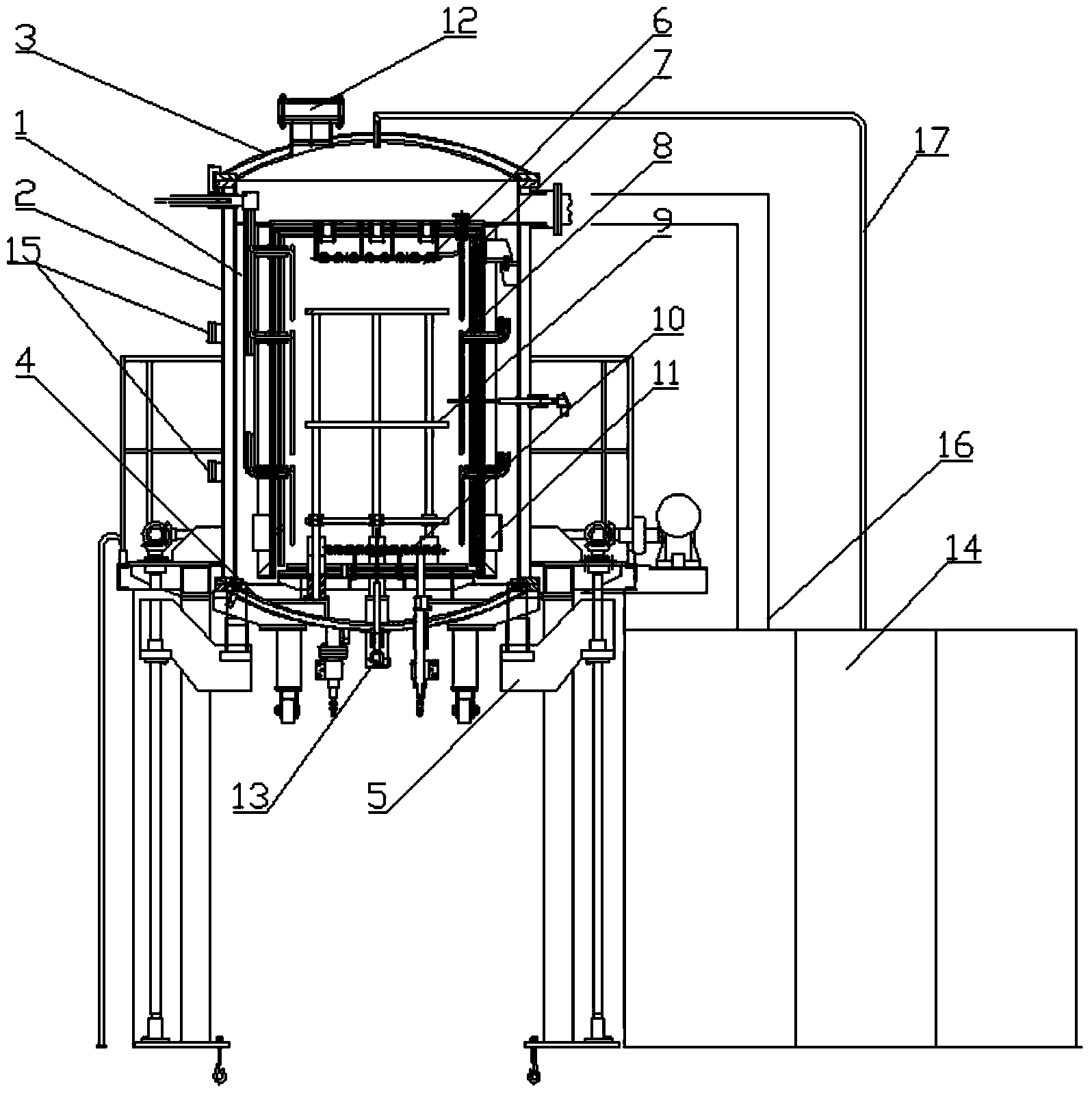

High temperature hydrogen sintering furnace

InactiveCN103644729ALow surface loadSmall temperature differenceMuffle furnacesRetort furnacesHydrogenMetallurgy

A high temperature hydrogen sintering furnace comprises a furnace pipe, a furnace body, an electric system and a vacuum system. The furnace pipe is installed in the furnace body, an upper head is fixed on the upper portion of the furnace body, a lower head is arranged on the lower portion of the furnace body, the upper head is connected with a hydrogen pipeline, the lower head is connected with a lifting system, the lower head is driven by the lifting system to open and close the furnace body, the upper portion of the furnace body is connected with the vacuum system through a connector, a reflection screen, an upper heating body, a lateral heating body and a lower heating body are hung on the inner wall of the furnace pipe, and a material rack is fixed on the lower head. An air flue is arranged on the lower portion of the furnace pipe, and a cooling water inlet / outlet is formed in the furnace body. An explosion venting port is formed in the upper head, and a thermocouple is arranged on the lower head. The furnace is used for sintering novel materials under the vacuum and high temperature states, is widely used in the fields of new energy development, heat treatment, powder metallurgy, ceramic metallization and the like, is especially suitable for vacuum arc extinguishing sintering, and achieves vacuum seal ceramic metallization.

Owner:宝钛特种金属有限公司

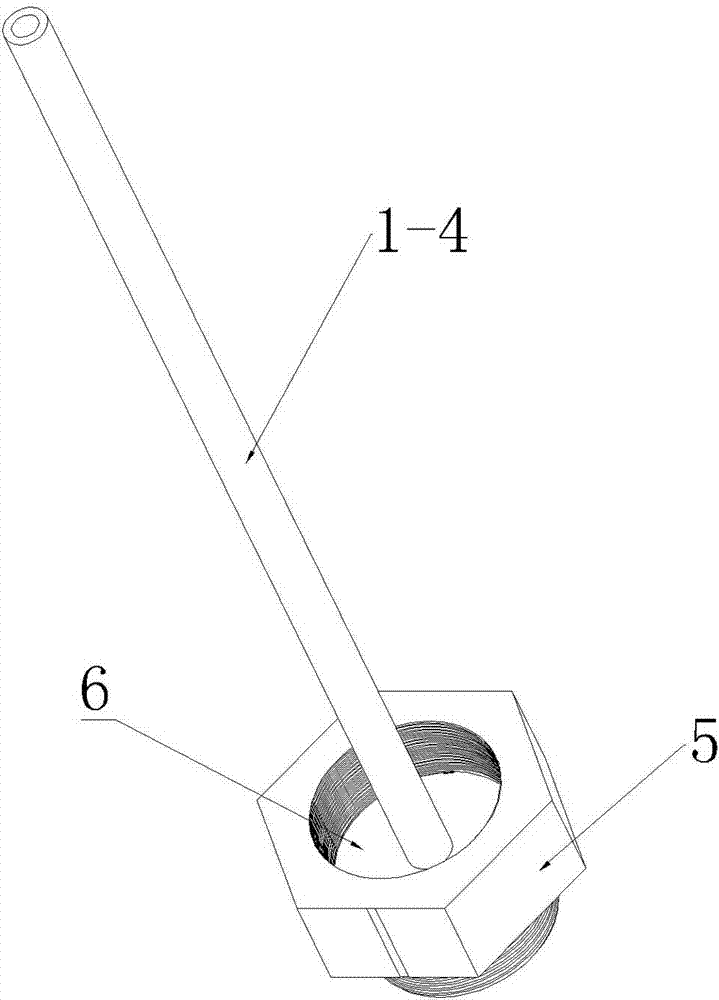

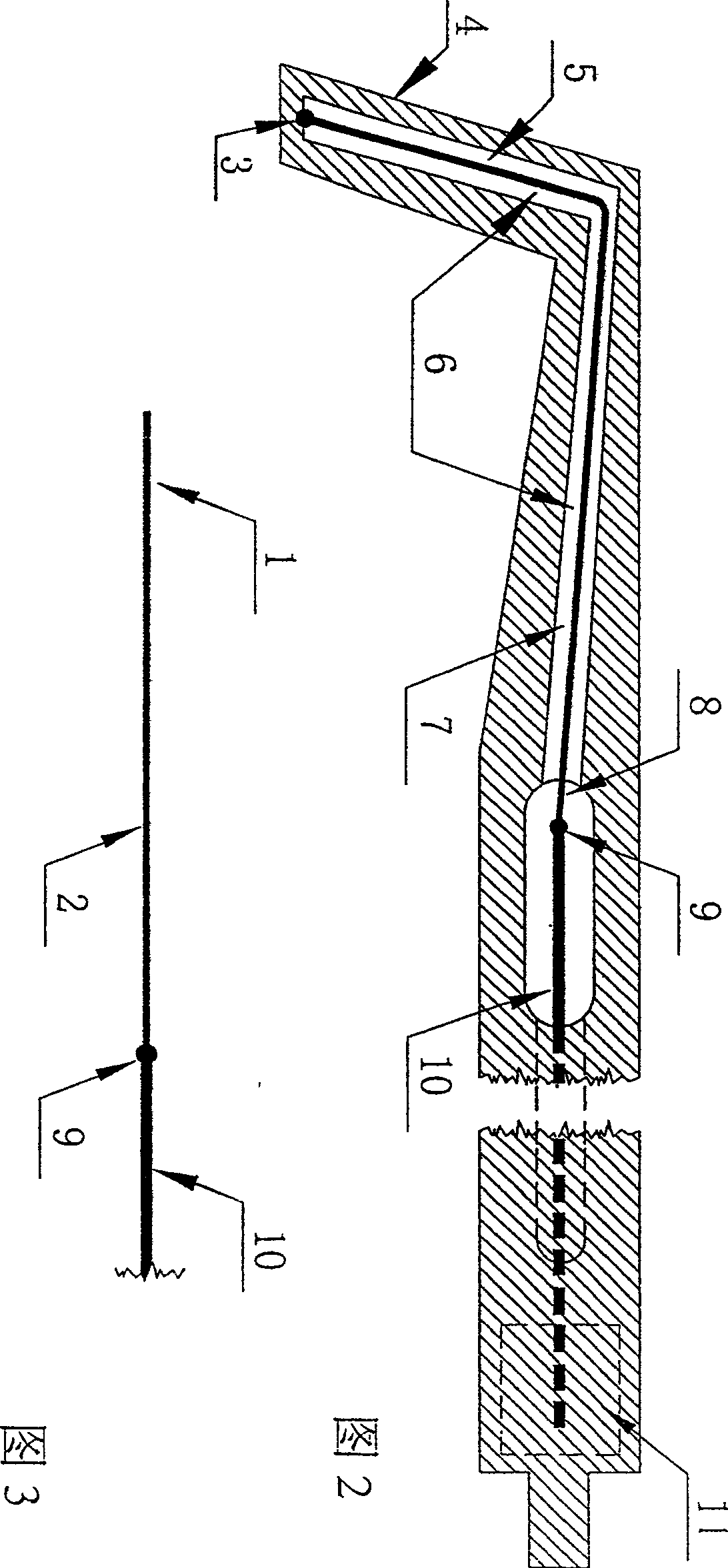

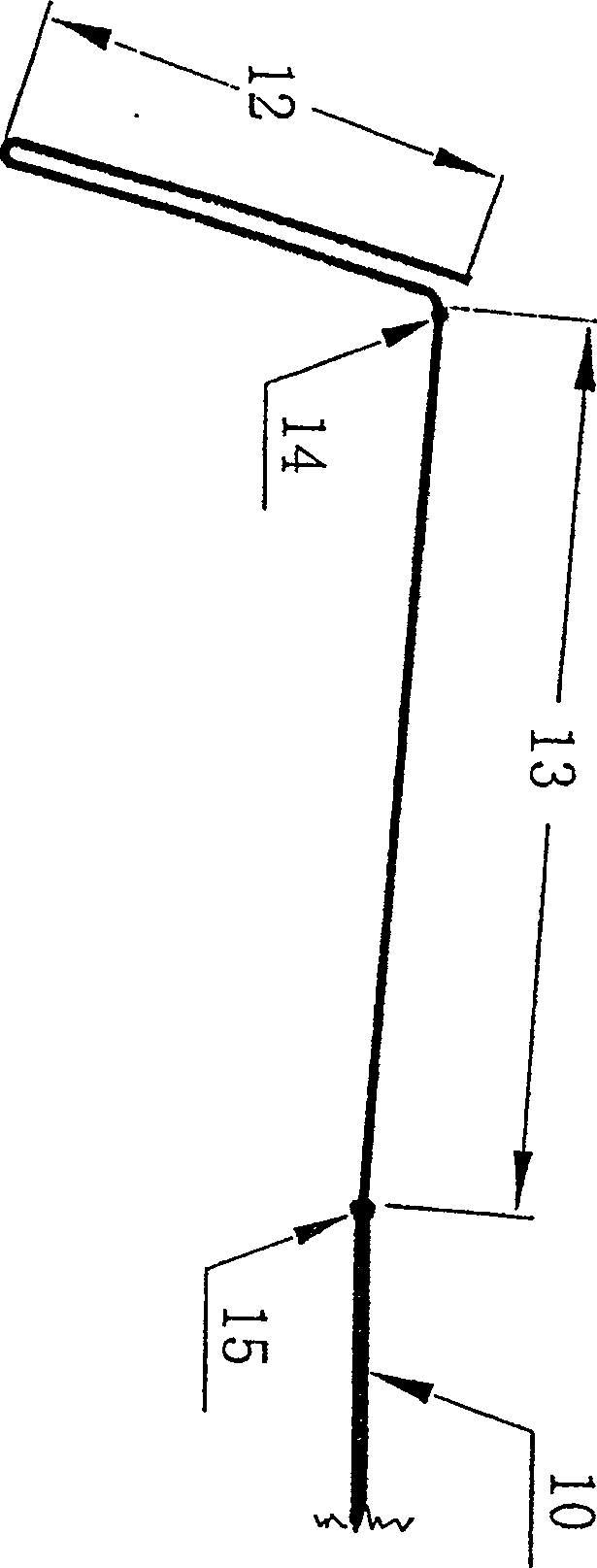

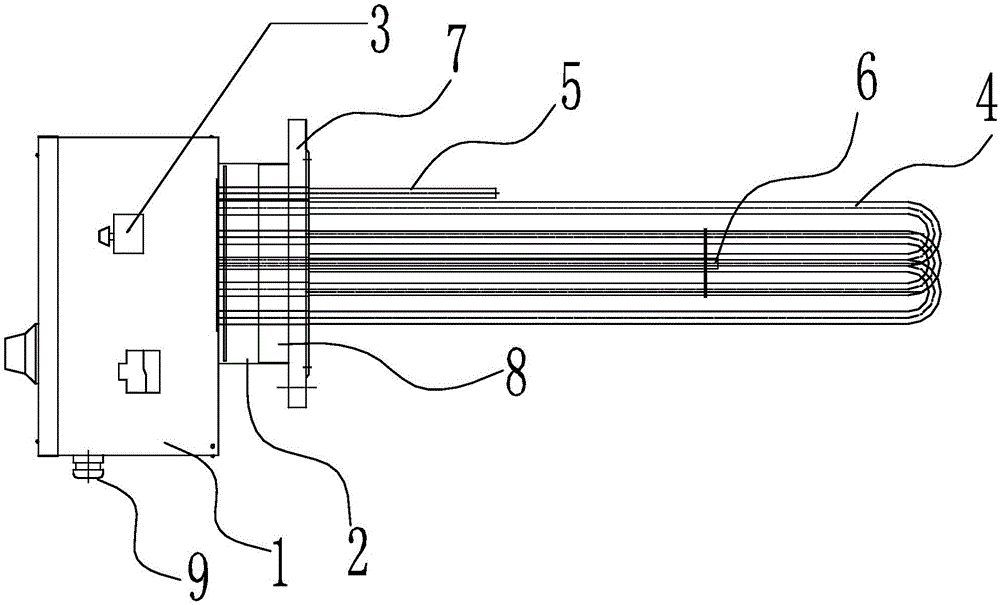

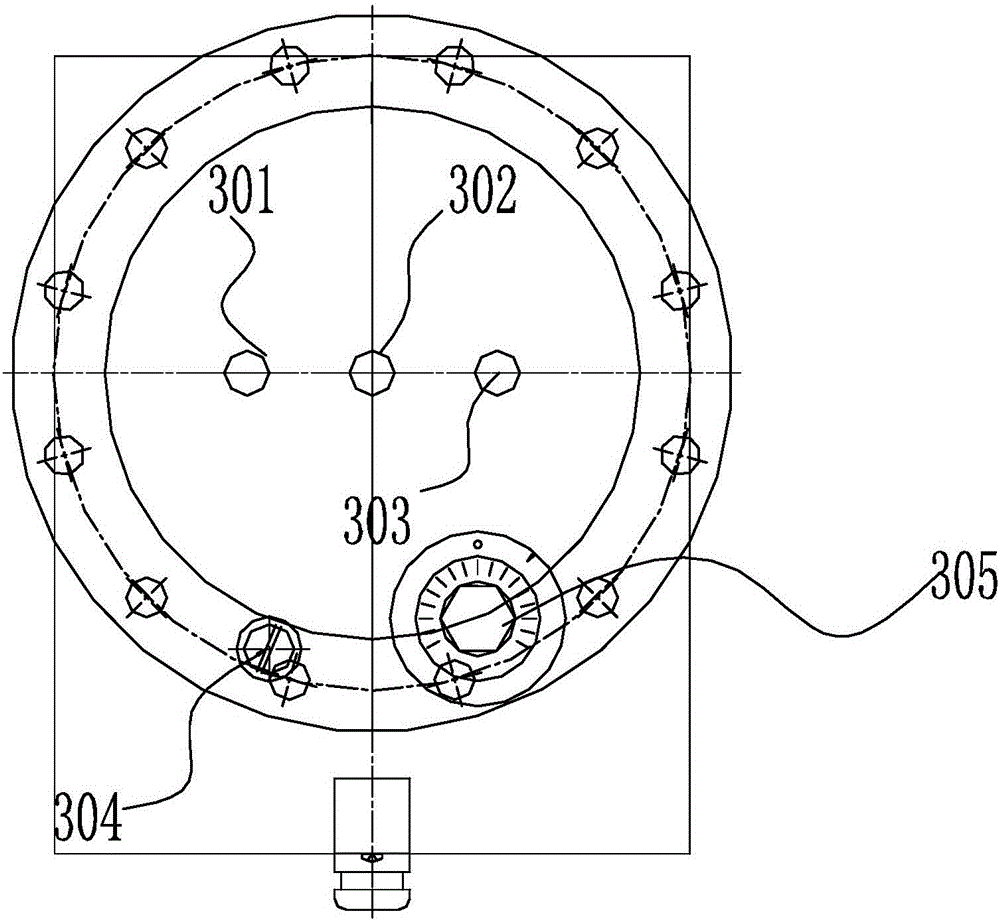

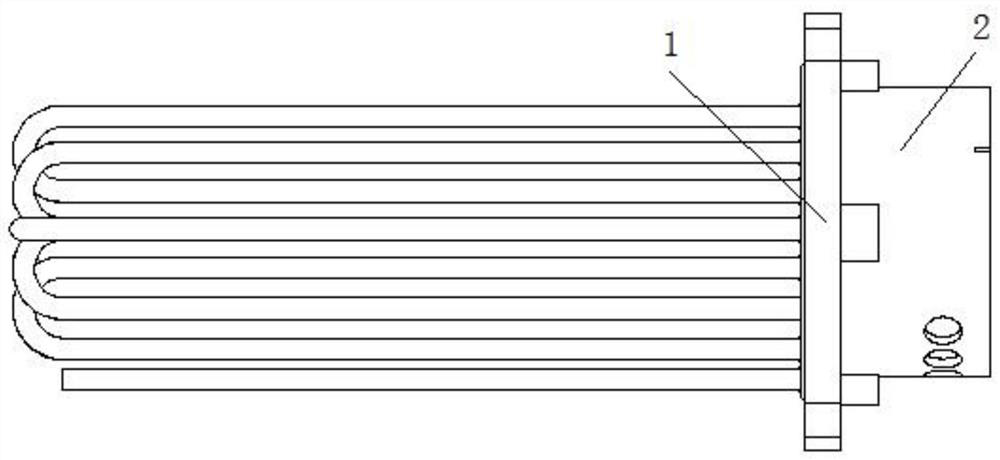

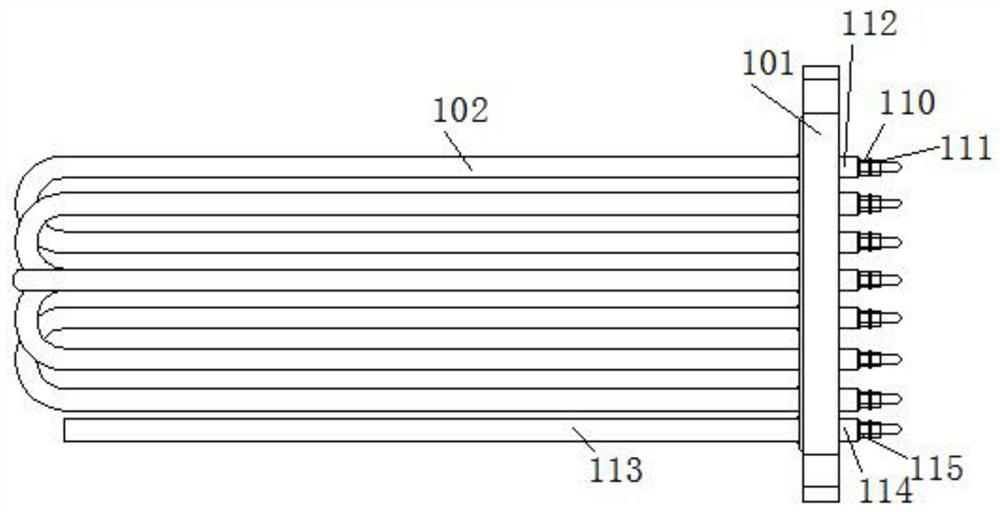

Straight rod detachable type electric heating pipe with single-end U-shaped pipe

PendingCN108541092AExtended service lifeSimple structure and principleOhmic-resistance waterproof/air-tight sealsHeating element shapesEngineeringBinding post

The invention discloses a straight rod detachable type electric heating pipe with a single-end U-shaped pipe, and belongs to the technical field of electric heating pipes. The electric heating pipe comprises a sealed bottom, the top is provided with a high-temperature porcelain head and two metal steel pipes which are different in lengths and are connected side by side, the top of the high-temperature porcelain head is further connected with a binding post, a U-shaped single-port magnesium oxide pipe is arranged inside the pipe body of each metal steel pipe, each U-shaped single-port magnesiumoxide pipe extends towards the bottom from the one-third position of the interior of the corresponding metal steel pipe, double-port magnesium oxide pipes matched with two ends of each U-shaped single-port magnesium oxide pipe are arranged at the two ends of each U-shaped single-port magnesium oxide pipe respectively, the U-shaped single-port magnesium oxide pipes are wrapped with the double-portmagnesium oxide pipes, and an electric resistance wire is paved inside each U-shaped single-port magnesium oxide pipe. According to the electric heating pipe designed in the invention, the heating efficiency is improved, the service life is prolonged, and the electric heating pipe is simple in structure and convenient to maintain.

Owner:镇江市恒升达化工科技有限公司

Electric heater of low-pressure casting machine

An electric heater of a low-pressure casting machine comprises an radiant tube, an electric element and an insulating frame; the electric element which is made of a flat-belt-shaped electrothermal alloy material and spirally wound around the insulating frame is reasonable in design, compact in structure, large in superficial area, high in heating power, uniform in heat radiation, reliable in operation, convenient to maintain and long in service life; the electric element which is made of an iron-chromium-aluminum-alloy material is high in electrical resistivity, small in resistance temperature coefficient, high in oxidization and corrosion resistance, long in high-temperature-resistant service life, light in weight and low in price, the material is saved, the size specification of the electric element is enlarged, surface load is reduced, and therefore the service life can be prolonged. A silicon carbide high-temperature refractory material is used for manufacturing the radiant tube, the radiant tube is high in heat conductivity, high in high-temperature intensity, resistant to abrasion, thermal shock and erosion and high in molten aluminum corrosion resistance and has satisfactory service life.

Owner:重庆德秋建设工程有限公司

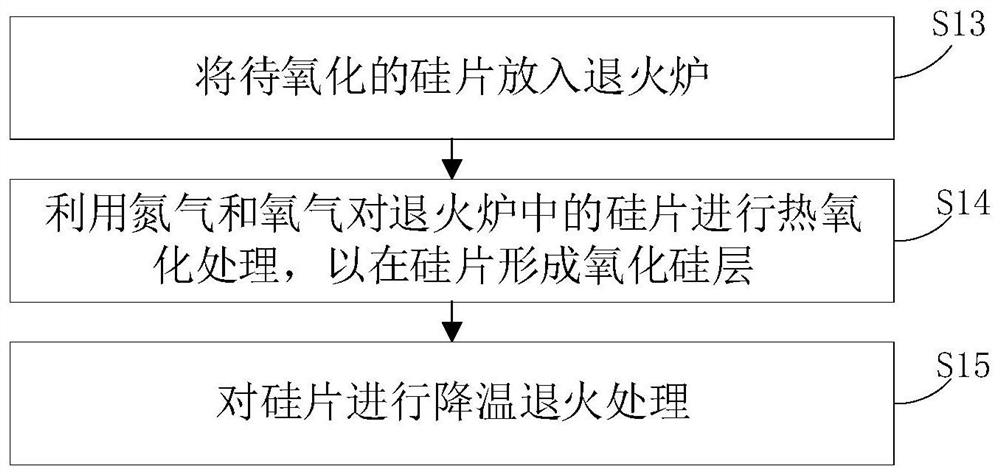

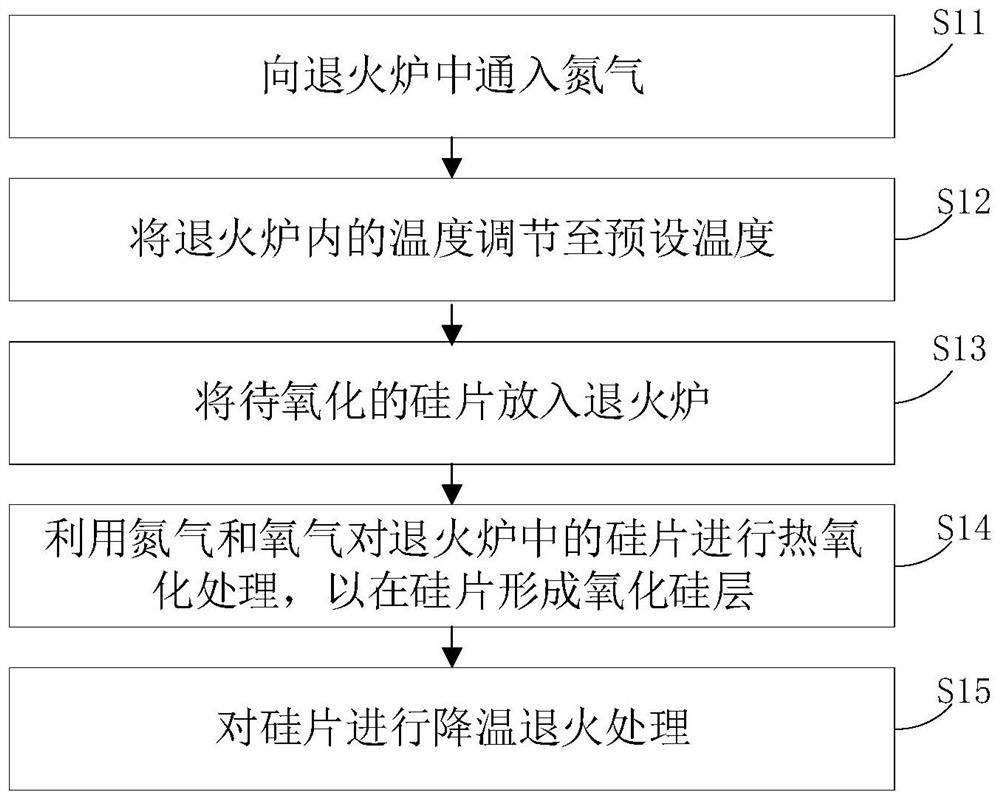

Annealing method of crystalline silicon solar cell, and crystalline silicon solar cell

PendingCN113782636ALow surface loadImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationPhysicsCrystalline silicon

The invention is suitable for the technical field of solar cells, and provides an annealing method of a crystalline silicon solar cell, and the crystalline silicon solar cell. The annealing method of the crystalline silicon solar cell comprises the following steps: putting a silicon wafer to be oxidized into an annealing furnace; carrying out thermal oxidation treatment on the silicon wafer in the annealing furnace through nitrogen and oxygen, so as to form a silicon oxide layer on the silicon wafer, wherein the proportion range of the oxygen is 75-90%, and the proportion range of the nitrogen is 10-25%; and cooling and annealing the silicon wafer. Therefore, the surface of the silicon wafer can be better passivated, the surface load of minority carriers is reduced, and the photoelectric conversion efficiency is improved. Meanwhile, a more compact silicon oxide layer can be generated, and the PID of the battery piece is improved.

Owner:TIANJIN AIKO SOLAR ENERGY TECH CO LTD +3

Wire heat-peeling forceps

InactiveCN100514769CMeet technical requirementsIncrease surface areaLine/current collector detailsApparatus for removing/armouring cablesThermoplasticElectrical resistance and conductance

Conductor thermal stripping pliers relate to electric heating tools and are special tools for stripping thermoplastic plastic sheaths. It is widely used in thermal stripping of wire insulation in aerospace, military and industrial industries. In the present invention, a heat pipe type heating structure is arranged in the stainless steel tweezers profile product, the front end is a blade for stripping wires, and a U-shaped resistance wire is arranged in the heat pipe at the blade, and the U-shaped structure is used to replace the original I-shaped structure at the blade. Resistance wire, thus doubling the effective power accordingly. In the supporting part, the original single-strand resistance wire is changed into double-strand parallel connection, the surface area of the resistance wire in this part is doubled, the surface load is reduced by half, and the effective resistance and reactive power loss are reduced by half, and the hot and cold joints are moved into the The body meets the technical requirements of the heat pipe. As a result, the reactive power loss of the product is reduced, and the performance is obviously greatly improved.

Owner:董一伟

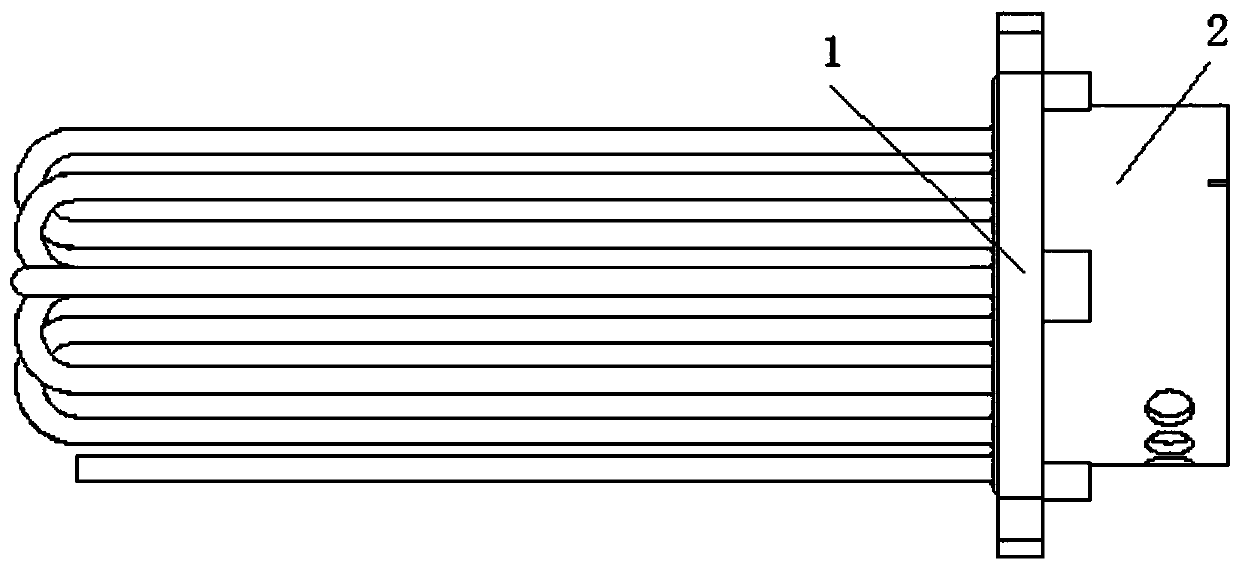

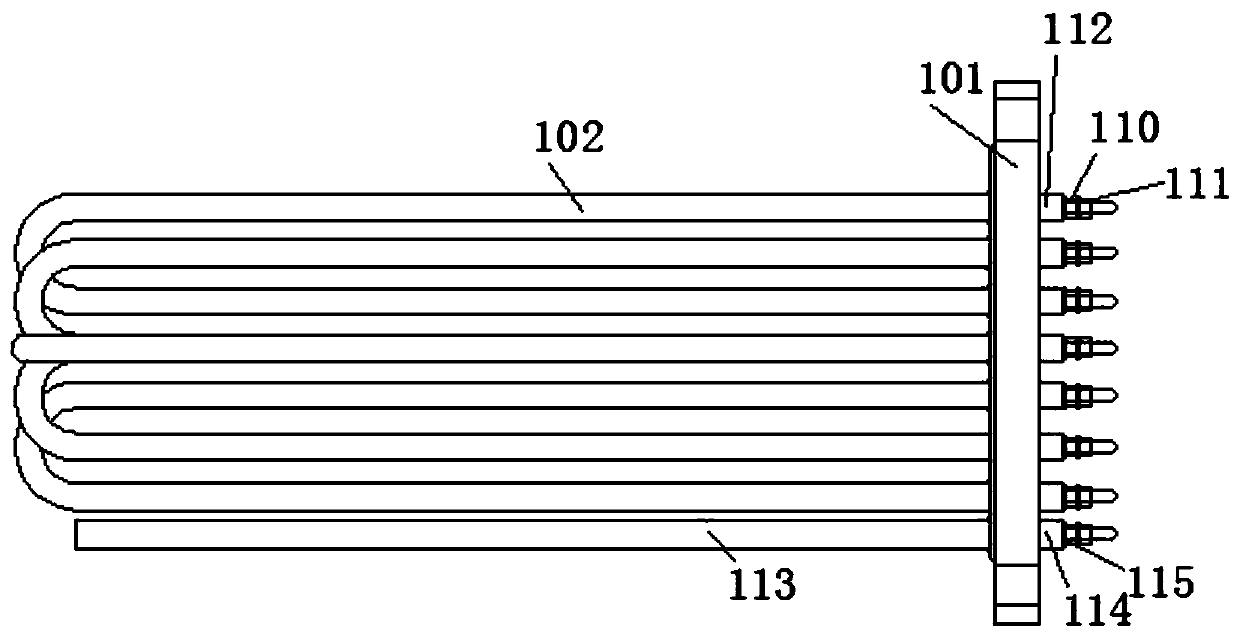

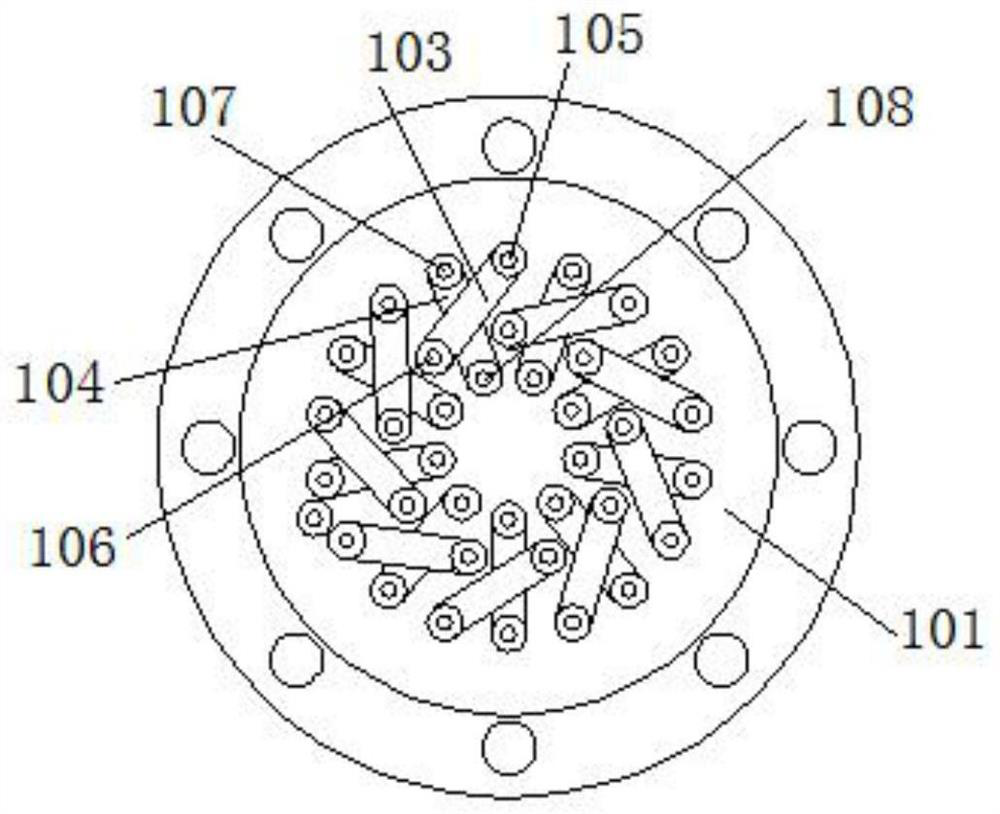

High-safety electric heater

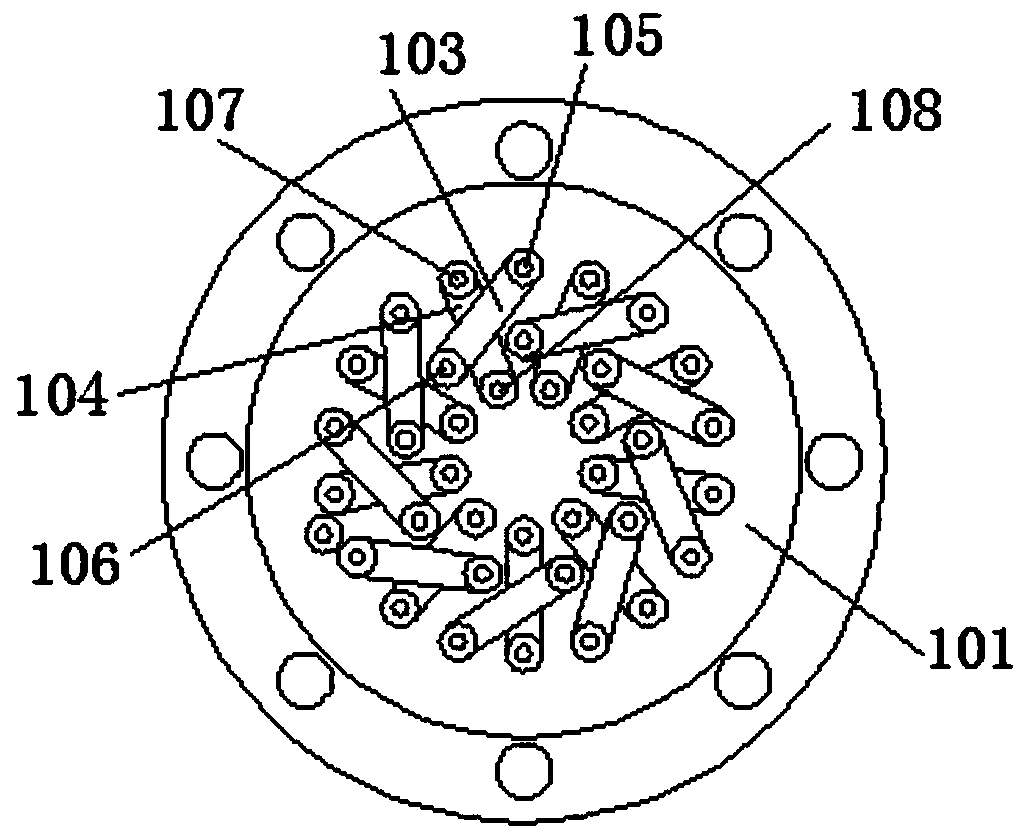

ActiveCN110798911ADischarge in timeReduce volumeOhmic-resistance heating detailsHeating element shapesMetal workingElectric wire

The invention provides a high-safety electric heater, which comprises an electric heating assembly and an electric heating tube shield, wherein the electric heating assembly comprises a fixed flange and 18 U-shaped tubes, the fixed flange is further provided with a temperature sensor, and the electric heating tube shield comprises a wiring shield and a protective cover. According to the invention,the U-shaped tubes can be made shorter under the condition that the diameter is not changed, a smaller container can be selected after the U-shaped tubes are made shorter, and the heat dissipation area is increased due to the fact that the number of the distributed U-shaped tubes is large, so that the surface load is low, and the service life is longer; the wiring shield and the protective coverare molded at one time by a mold, so that the working hours consumed in original metal processing are greatly shortened, the material is an insulating high-temperature-resistant material, and the insulating property is greatly improved. The inner wall of the wiring shield is further provided with a temperature sensor jack, so that an electric wire of the temperature sensor is not contacted with ahigh voltage part in the heater, the safety is ensured, and the mounting and dismounting of the protective cover are not influenced.

Owner:扬中市诺贝电气有限公司

Wastewater treatment system for bypass sludge discharge

PendingCN114644435AAchieve reductionOrganic load reductionTreatment using aerobic processesMultistage water/sewage treatmentSludgeOutfall

The invention discloses a bypass sludge discharge wastewater treatment system which comprises an adsorption reaction tank, the adsorption reaction tank is provided with a reaction tank water inlet pipe, a sewage inlet pipe, a water passing hole and a reaction tank water outlet pipe, the reaction tank water outlet pipe is connected with a sludge discharge sedimentation tank through a water inlet pump, and the sludge discharge sedimentation tank is provided with a sludge outlet and a sludge discharge sedimentation tank water outlet pipe. A water outlet pipe of the sludge discharge sedimentation tank and a water passing hole are respectively connected with the delay aeration tank, a water outlet pipe of the delay aeration tank and a water inlet pipe of the delay aeration tank are arranged on the delay aeration tank, the water outlet pipe of the delay aeration tank is connected with a water inlet pipe of the backflow sedimentation tank, and a water outlet and a backflow pipe are arranged on the backflow sedimentation tank; and the return pipe is respectively connected with a water inlet pipe of the reaction tank and a water inlet pipe of the delayed aeration tank through a sludge return pump. The adsorption effect of discharged sludge is utilized to remove part of COD and refractory organic matters in to-be-treated wastewater, the surface load of the sedimentation tank with the same area is low, the SS of effluent of the sedimentation tank is low, the process is simple, and energy conservation and consumption reduction are realized.

Owner:苏州博净源环境科技有限公司

Filter element and hydraulic circuit with such a filter element

ActiveUS10213709B2Cost-effectiveMinimize dangerMembrane filtersStationary filtering element filtersHydraulic circuitFilter media

A filter element has a preferably multilayer structure of a pleated filter medium (3) with a plurality of individual filter pleats (5, 7). Due to an alternating sequence of filter pleats (5) with a first pleat height (h1) and filter pleats (7) with a second pleat height (h2), more effective filter surfaces are available than with filter pleats with a uniform pleat height. Upon throughflow by a fluid to be filtered, a lower surface load for the filter medium (30 and lower passage speed of the fluid are present during filtration. A static loading of the filter medium (3) during operation of the filter is then reduced. A hydraulic circuit has such a filter element (1).

Owner:FILTERTECHN

Full-automatic electric heater for water tank

InactiveCN106382751AEasy to assemble and disassembleExtended service lifeFluid heatersElectricityWater tanks

Owner:ANQING SANWEI ELECTRICAL

A composite textile printing and dyeing wastewater treatment process

ActiveCN105967453BReduce COD contentLow surface loadSpecific water treatment objectivesTreatment involving filtrationConstructed wetlandTextile printer

The invention relates to the technical field of treatment of textile printing and dyeing wastewater, in particular to a combined process for treating textile printing and dyeing wastewater, comprising the steps such as neutralizing, coagulating and precipitating, filtering with an O / A combined biofilter, activating with an active enzyme promoter, adsorbing with a constructed wetland tank, precipitating, sterilizing, and discharging; the combined process provided by the invention has good wastewater purifying effect and enables continuous treatment of batch production wastewater.

Owner:ANHUI GUONENG YISHENG ENVIRONMENTAL PROTECTION SCI & TECH

A high safety electric heater

ActiveCN110798911BDischarge in timeReduce volumeOhmic-resistance heating detailsHeating element shapesThermodynamicsMetal machining

The invention provides a high-safety electric heater, which includes an electric heating assembly and an electric heating tube shield. The electric heating assembly includes a fixing flange and 18 U-shaped tubes. The fixing flange is also provided with a temperature sensor. The electric heating tube shield includes a wiring shield and a protective cover. The present invention can make the U-shaped tube shorter when the diameter is constant, and can choose a smaller container after being shortened. Due to the distribution of the U-shaped tube The number of roots is more, the heat dissipation area is increased, the surface load will be lower, and the service life will be longer; the wiring shield and the cover are formed by the mold at one time, which greatly shortens the working hours of the original metal processing, and the material is made of insulating and high temperature resistant materials. , the insulation performance has been greatly improved. There is also a temperature sensor jack on the inner wall of the wiring shield, so that the wire of the temperature sensor will not come into contact with the high-voltage part of the heater, ensuring safety without affecting Cover installation and removal.

Owner:扬中市诺贝电气有限公司

Trolleys for trolley-type resistance furnaces

The invention provides a bogie hearth for a bogie hearth type resistance furnace. The bogie hearth for the bogie hearth type resistance furnace is formed by cast iron which is used for bearing workpieces, a fire-proof layer, a first thermal insulation layer, a second thermal insulation layer, a base plate layer, a heating element, a thermal preservation brick and a bogie hearth body which are arranged from top to bottom sequentially; the base plate layer is formed by a plurality of strip-shaped furnace bottom plates in a splicing mode; the furnace bottom plates are made of heat resisting steel; splicing positions of the adjacent furnace bottom plates are in hasp modes; splicing positions of the furnace bottom plates are provided with thermal expanded and cold contracted gaps; the heating element is bent to be in a wave band shape through belts; the heating element is fixed on the thermal preservation brick. The bogie hearth for the bogie hearth type resistance furnace has the advantages of guaranteeing the furnace bottom temperature; improving the surficial area of the heating element, reducing the surface load of the heating element and prolonging the service life of the heating element due to the fact that the heating element is arranged on bogie hearth; meanwhile avoiding short circuit due to the fact that oxidized iron sheets fall on the heating element and improving the production safety due to the furnace bottom plates.

Owner:徐州东创重工机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com