Annealing method of crystalline silicon solar cell, and crystalline silicon solar cell

A technology of solar cells and crystalline silicon, which is applied in the field of solar cells to achieve the effects of improving potential-induced attenuation, improving photoelectric conversion efficiency, and reducing surface loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

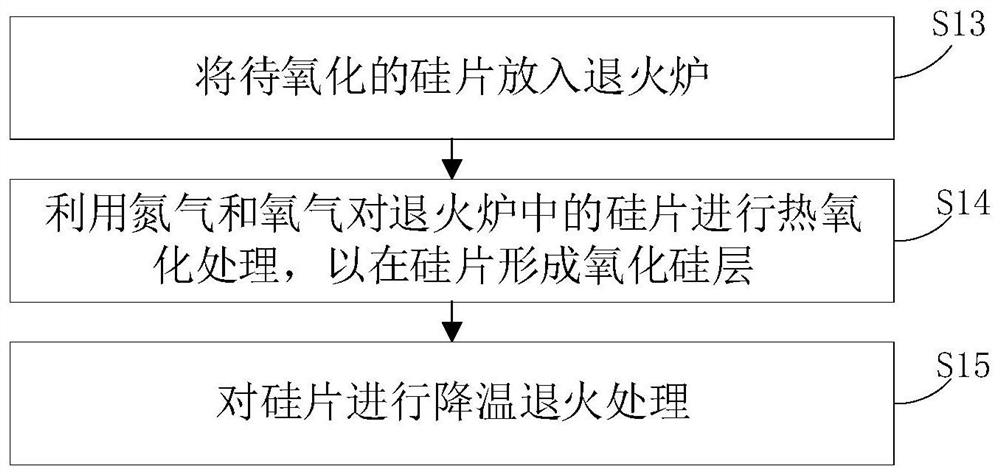

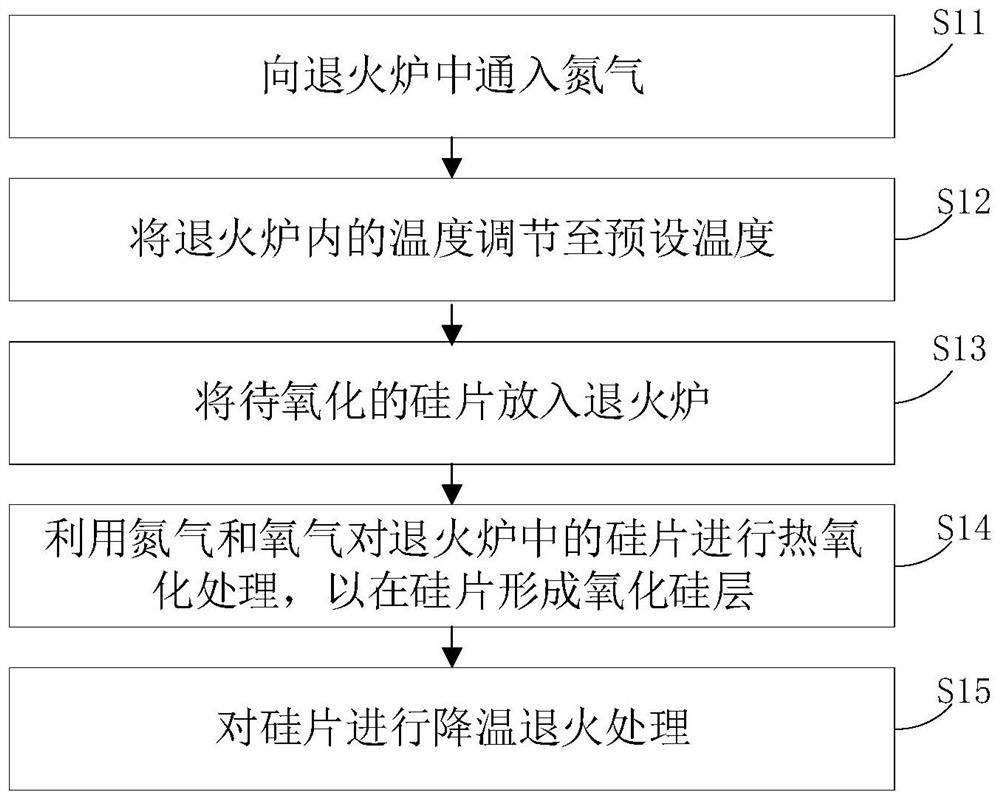

[0023] see figure 1 , the annealing method of the crystalline silicon solar cell of the embodiment of the present application, comprising:

[0024] Step S13: putting the silicon wafer to be oxidized into an annealing furnace;

[0025] Step S14: Perform thermal oxidation treatment on the silicon wafer in the annealing furnace with nitrogen and oxygen to form a silicon oxide layer on the silicon wafer, the proportion of oxygen is in the range of 75%-90%, and the proportion of nitrogen is in the range of 10%-25 %;

[0026] Step S15 : performing an annealing treatment on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com