Full-automatic electric heater for water tank

An electric heater, fully automatic technology, used in fluid heaters, lighting and heating equipment, etc., can solve the problems of cumbersome wiring, no heat dissipation tube sleeve, and high temperature of the protective cover, so as to reduce the consumption of materials and reduce the surface load. , the effect of simplifying the control design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

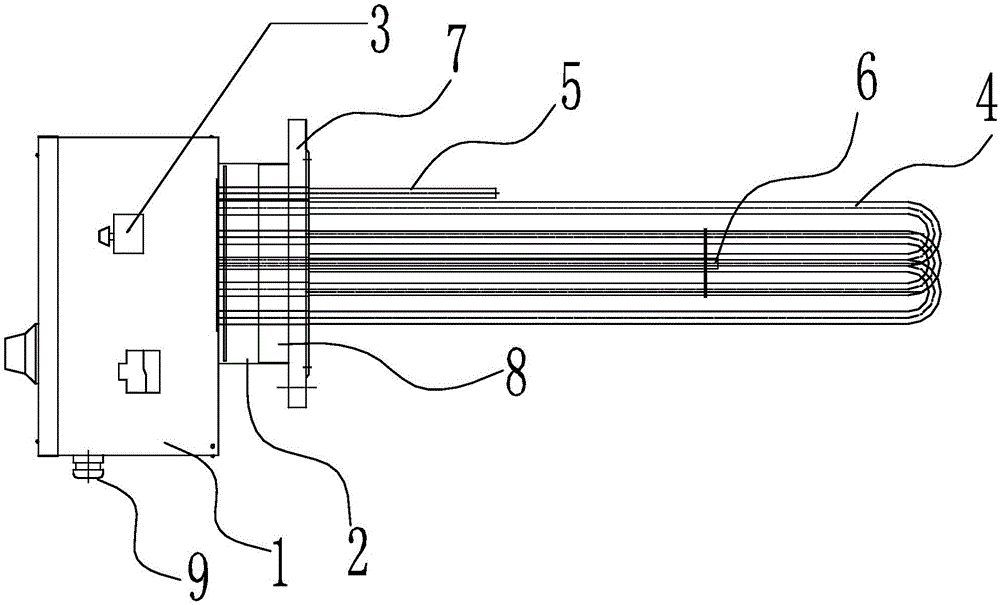

[0018] Example: Combine figure 1 : A fully automatic water tank electric heater, comprising a U-shaped electric heating element 4, a controller 3, a protective cover 1, a heat dissipation protection sleeve 2, a flange connector 7, a first temperature measuring device 5,

[0019] The controller 3 is installed in the protective cover 1, one end of the protective cover 1 is provided with an opening, one end of the heat dissipation protection sleeve 2 is connected to the opening, and the other end is connected to the flange connector 7, and the port of the U-shaped electric heating element 4 is connected to the flange. The blue connector 7 is connected, the first temperature measuring device 5 and the U-shaped electric heating element 4 are installed side by side at a certain height, and the U-shaped electric heating element 4 and the first temperature measuring device 5 are electrically connected to the controller 3 .

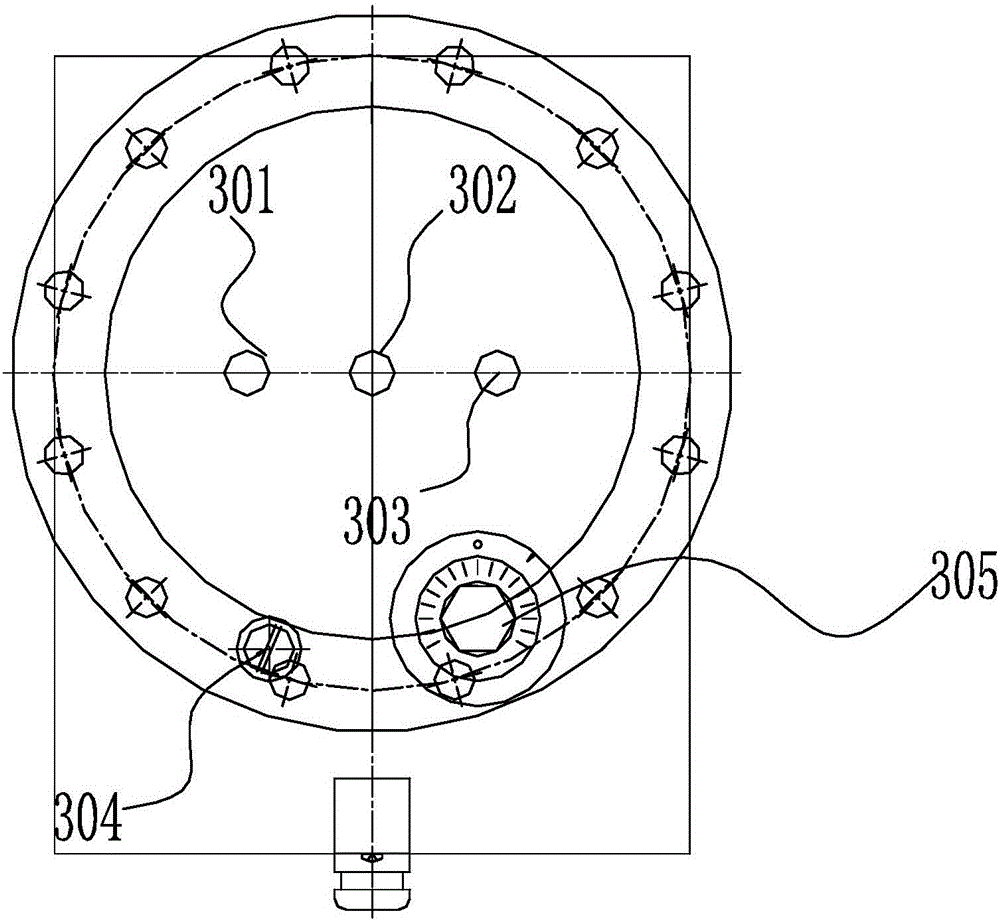

[0020] combine figure 2 : Further, the controller 3 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com