Improved multi-layer flat unit combined settling pond process

A technology of sedimentation tank and plate, applied in the direction of sedimentation tank, etc., can solve the problems of reducing cost, not conducive to improving work reliability, complex mechanical structure, etc., to achieve the effect of reducing cost, improving work reliability, and simplifying mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

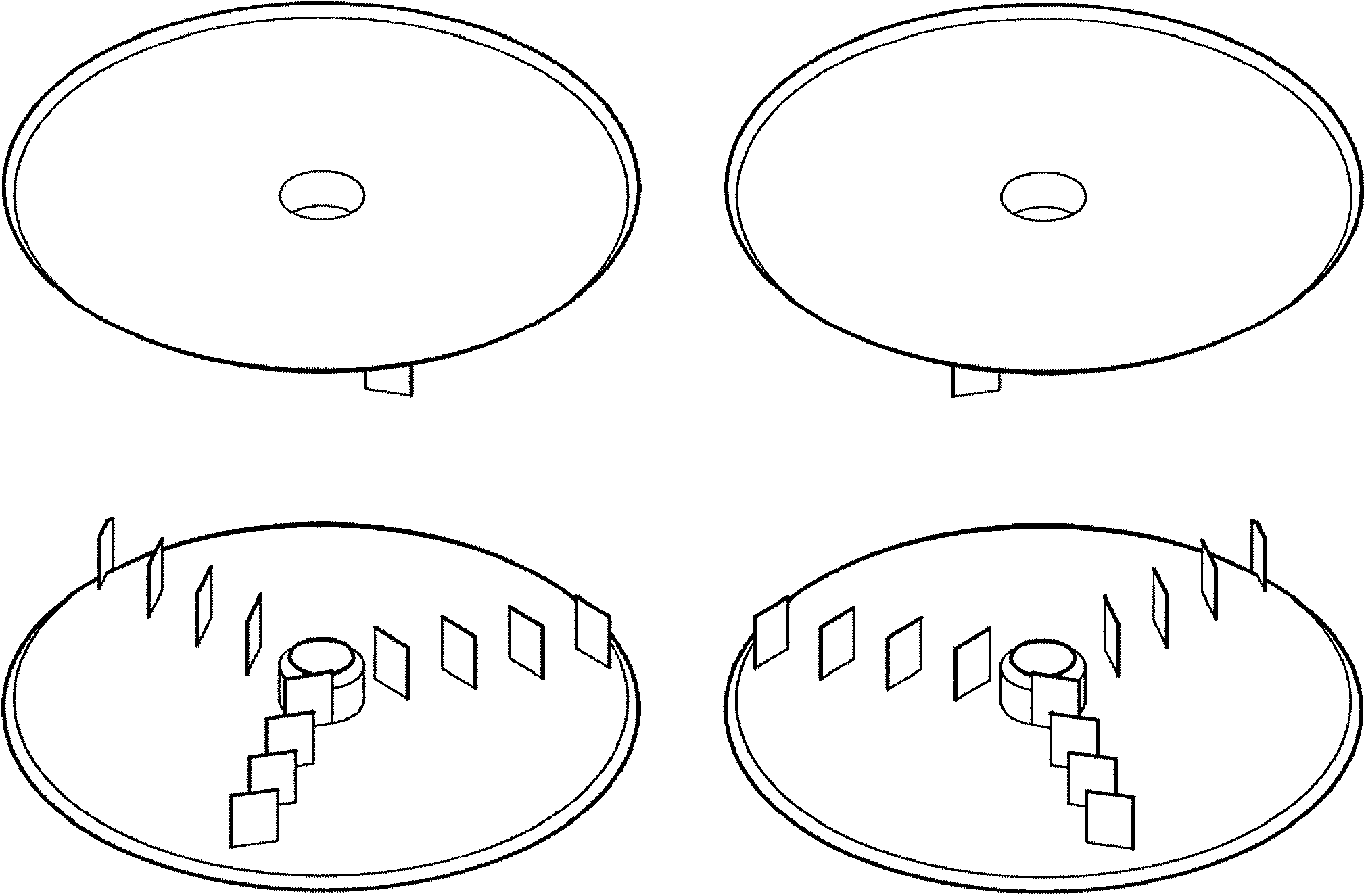

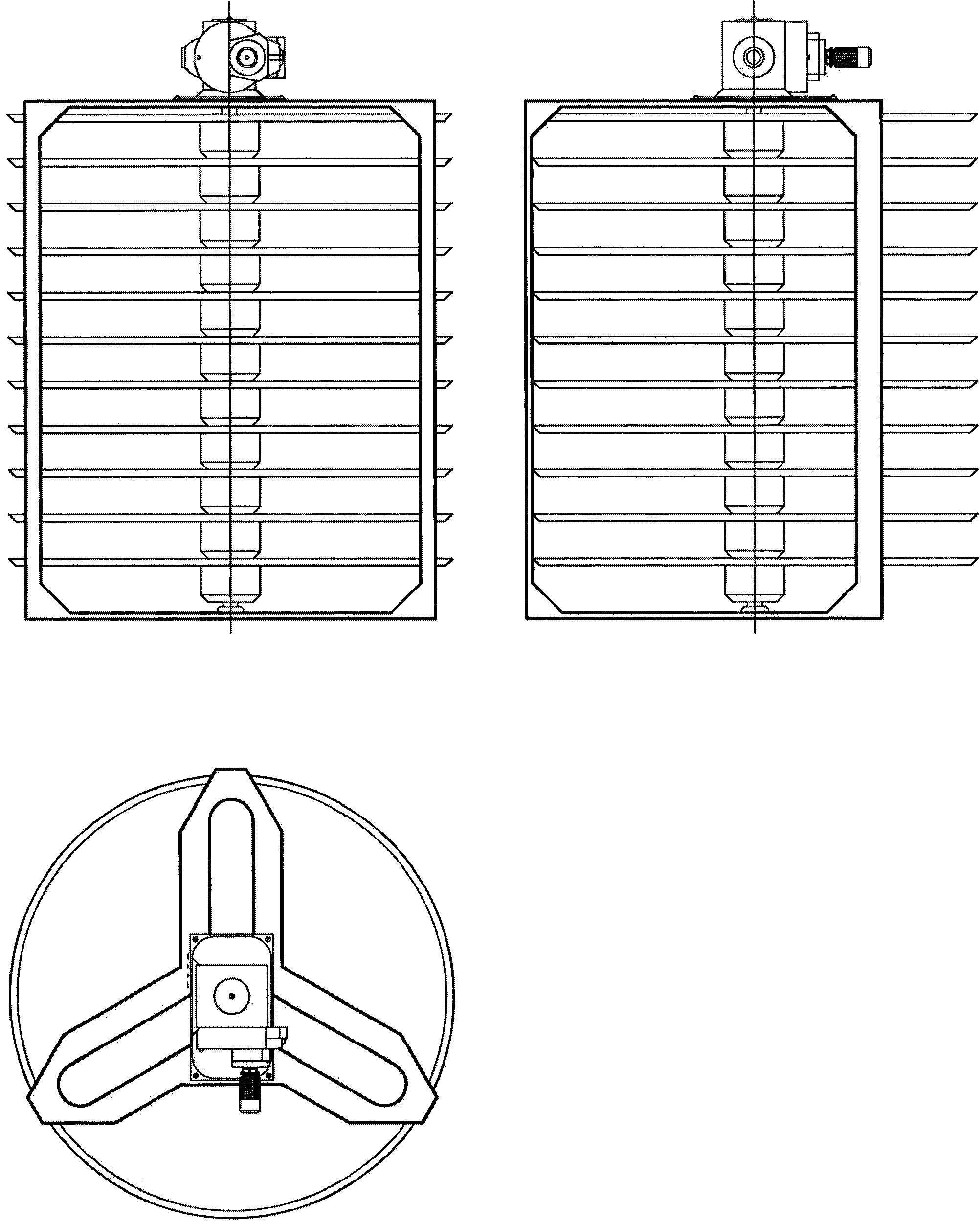

[0020] 1. The turntable is round, and the edge of the turntable is upturned to prevent the sludge from overflowing. A scraper is installed at the bottom of the turntable (the direction of the scraper in the odd and even layers is different), and the center of the turntable is opened to accommodate the central drive shaft and discharge downward. For sludge, set up a downpipe under the hole to avoid contact between sludge and clarified water;

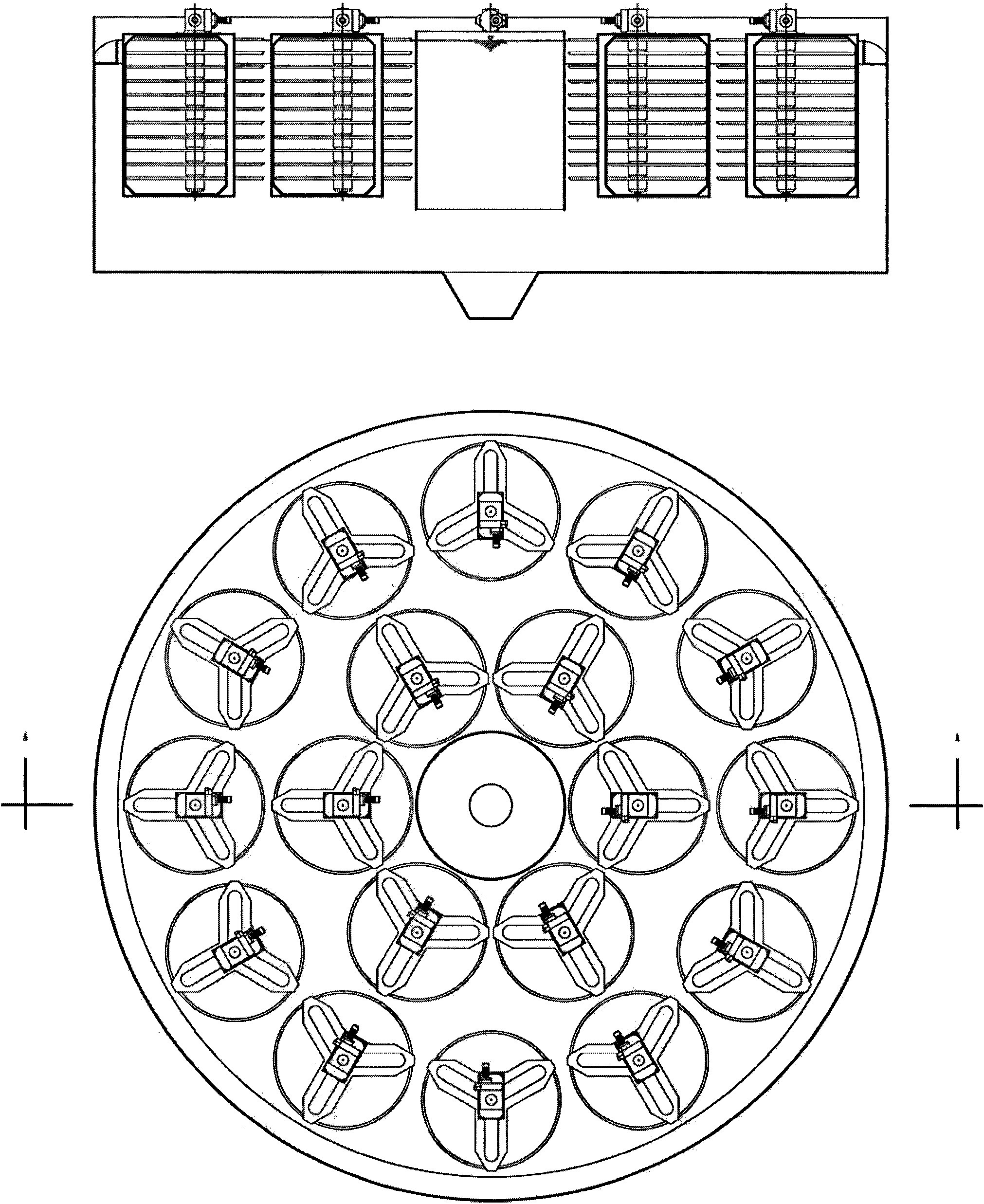

[0021] 3. The multi-layer turntable unit is composed of multi-layer turntables. The odd-numbered turntables are connected to the central transmission shaft to rotate, and the even-numbered turntables are fixed on the surrounding frame of the unit. The motor and transmission device are installed on the frame of the unit to drive the central transmission shaft. ;

[0022] 4. Both advection sedimentation tank and radial flow sedimentation tank can be used. Multiple multi-layer turntable units are placed in the upper clarification area of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com