High power, high frequency and high voltage rectifier transformer

A rectifier transformer, high-frequency high-voltage technology, applied in transformers, fixed transformers, transformer/inductor cores, etc., can solve the problems of transformer temperature rise, large winding loss, and difficult heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

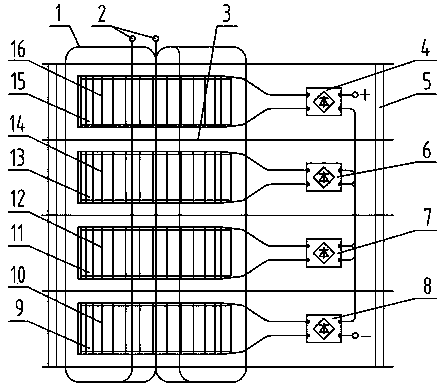

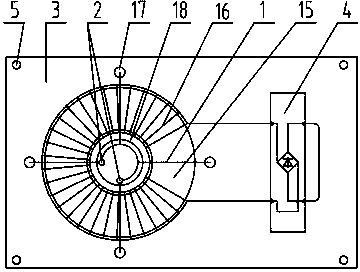

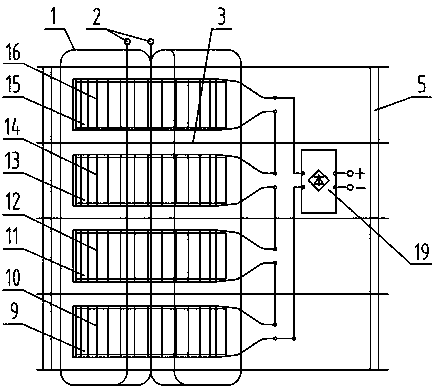

[0018] figure 1 with figure 2 In, a high-power, high-frequency and high-voltage rectifier transformer, including an iron core, a high-voltage winding, a rectifier bridge, and a low-voltage winding1. The high-power, high-frequency and high-voltage rectifier transformer also includes a support frame 5, and the iron cores are at least two. In the first embodiment, four iron cores are used, namely, the first iron core 15 and the second iron core 13 , The third iron core 11 and the fourth iron core 9, these iron cores are rectangular or ring-shaped ultra-microcrystalline transformer cores. The first iron core 15, the second iron core 13, the third iron core 11 and the fourth iron core 9 are sequentially arranged on the support frame 5. In the first iron core 15, the second iron core 13, the third iron core 11, and the fourth iron core 9, a space is left between adjacent iron cores. The high-voltage winding is composed of a first high-voltage sub-winding 16, a second high-voltage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com