Highly effective integral water purifying device

A water purification device and high-efficiency technology, applied in the field of water treatment, can solve problems such as secondary pollution, and achieve the effects of reducing surface load, reducing the dosage of medicine, and sufficient flocculation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

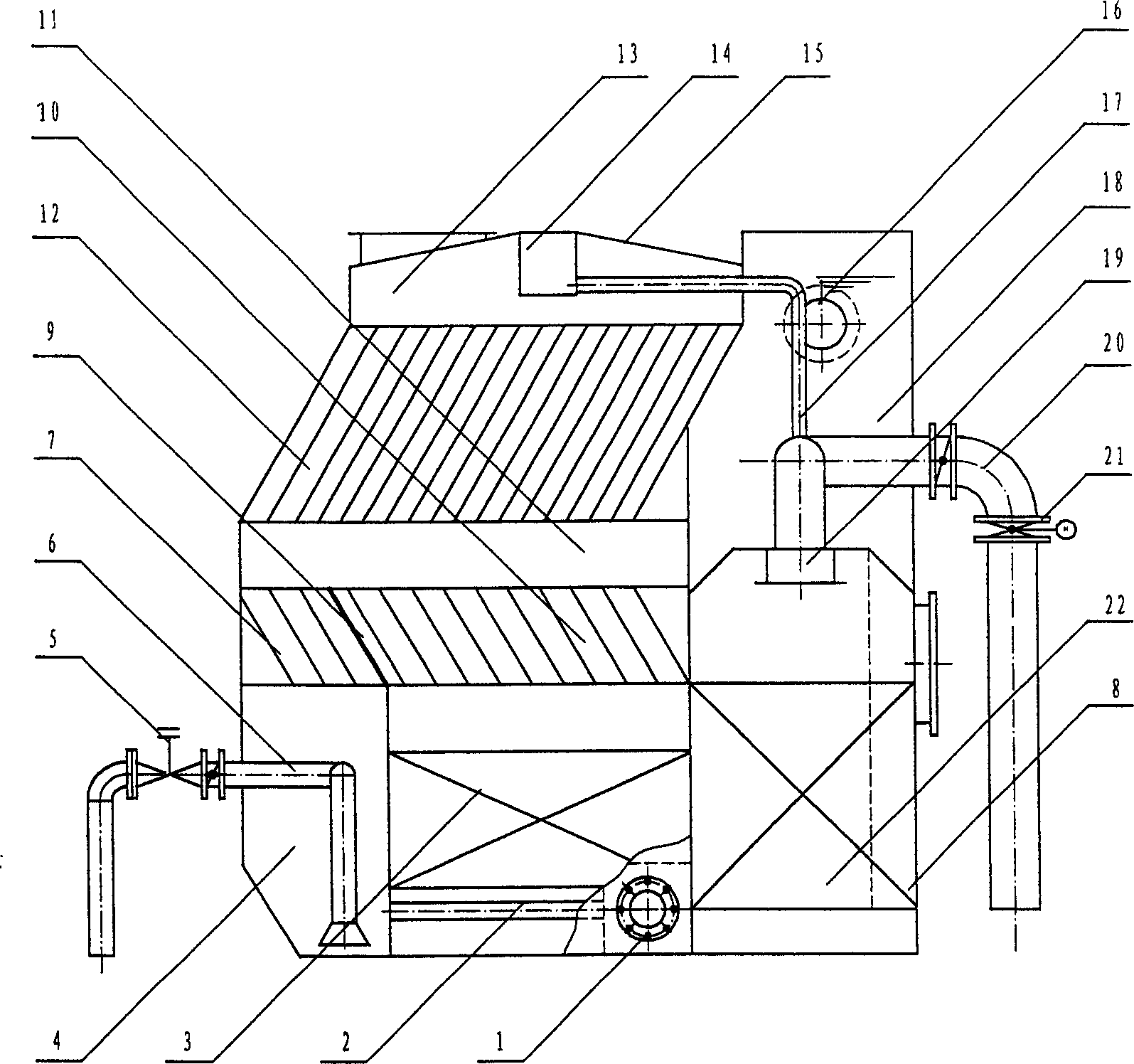

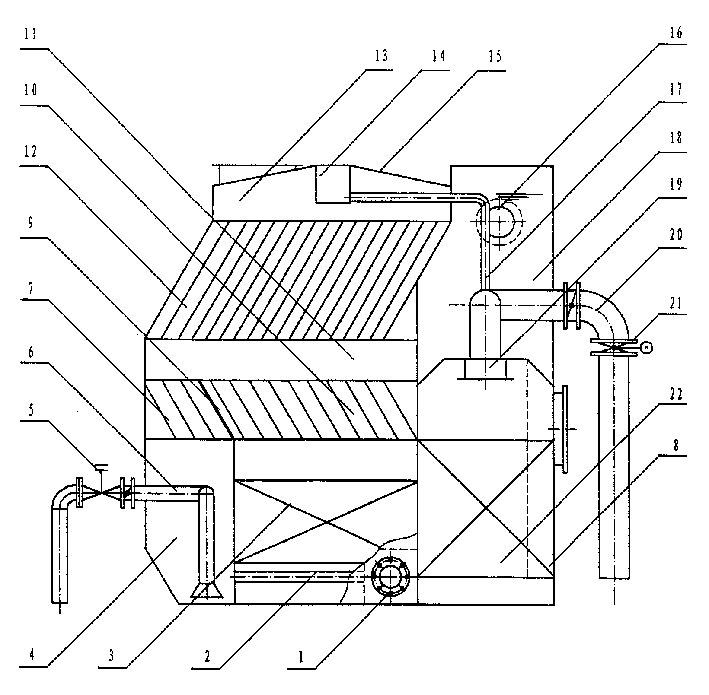

[0010] Fully-enclosed pressure-bearing and high-efficiency integrated water purification device, the reaction zone (3) is in the middle of the bottom of the body (15), and the water inlet pipe (1) installed at the bottom corner of the reaction zone (3) passes through the water distribution pipe (2) and the reaction zone (3) The water is connected, and the distance between the water distribution pipes (2) decreases gradually from the water inlet end to the end. The reaction area (3) with built-in spherical packing is on both sides of the sludge area (4) and the filter area (22). A mud discharge pipe (6) with a solenoid valve (5) is provided in the zone (4), and the solenoid valve (5) is connected to the signal of the electric control system, and the inclined pipe diversion zone (10) is arranged in the reaction zone (3) Above, the inclined tube mud collection area (7) is set above the sludge area (4), and the inclined tube diversion area (10) and the inclined tube mud collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com