Electric heater of low-pressure casting machine

A low-pressure casting and heater technology, applied in the field of low-pressure casting electromechanical heaters and low-pressure casting machines, can solve the problems of high price of nickel-chromium alloy electric heating elements, affecting the actual function of the radiant tube 1, and unfavorable maintenance and repair of electric heaters. Light weight, compact structure, the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

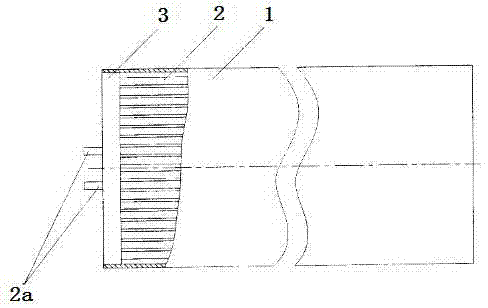

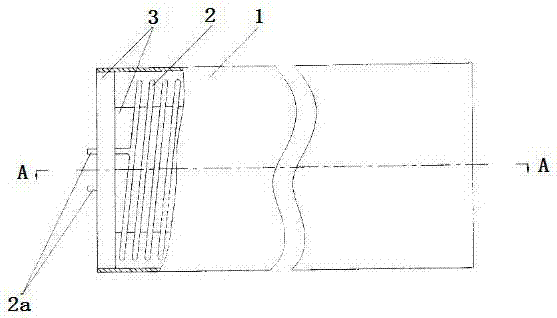

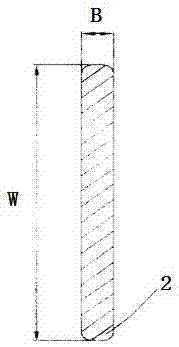

[0014] like figure 2 As shown, the low-pressure casting electromechanical heater of this embodiment is mainly composed of a radiant tube 1, an electric heating element 2 and an insulating frame 3, and is integrally installed in a holding furnace. The cross-section of the electric heating element 2 of the flat belt shape of the present invention is as image 3 As shown, the thickness B is in the range of 1-5mm, and the width W is in the range of 8-50mm. In this embodiment, a flat strip heating element 2 with a thickness B of 2.5mm and a width W of 20mm is used. Aluminum electrothermal alloys can also be used Ocr21Al6Nb, Ocr27Al7Mo2 and other grades of iron-chromium-aluminum electrothermal alloy materials. The electric heating element 2 is spirally wound on the ceramic heat-resistant insulating frame 3, and its power connector 2a passes through the end face of one end of the insulating frame 3, and is connected with a 220-volt AC power supply. In this embodiment, the radiant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com