Finned tube heater and its production method

A production method and technology of finned tubes, which are applied in the field of electric heating, can solve the problems of large surface load, high manufacturing cost and short service life of heaters, and achieve the effects of small surface load, saving raw materials and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

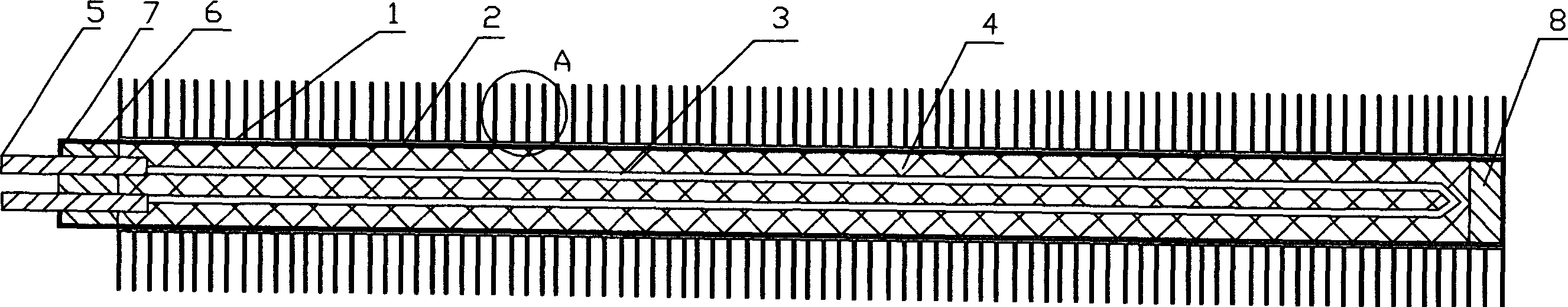

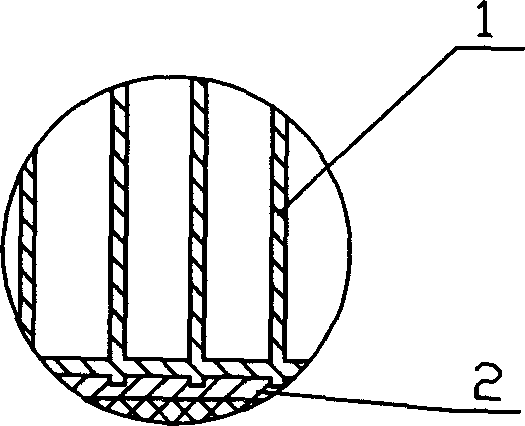

[0014] Such as figure 1 and figure 2 As shown, the present invention has a heating tube shell 2 made of a metal tube. In the heater shell 2, a heating element 3 is fixed by a fixing frame 6. A power terminal 5 is arranged at the left end of the heating tube shell 2. In the heater shell 2 2 is filled with insulating material 4, an insulating sealant 7 is filled at the port of the heater shell 2, a metal head 8 is installed at the right end of the heater shell 2, and a finned tube 1 is arranged on the outer surface of the heater shell 2, The lower part of the finned tube 1 is embedded in the heater shell 2, and the depth of the finned tube 1 embedded in the heater shell 2 is 0.1-0.5mm.

[0015] During manufacture, heating element 3 is fixed in a heater shell 2 that adopts metal tube to make, and said heating element 3 can adopt nickel-chromium alloy or cermet or resistance wire. The power terminal 5 is drawn out from the left end of the heating tube shell 2 and the port of th...

Embodiment 2

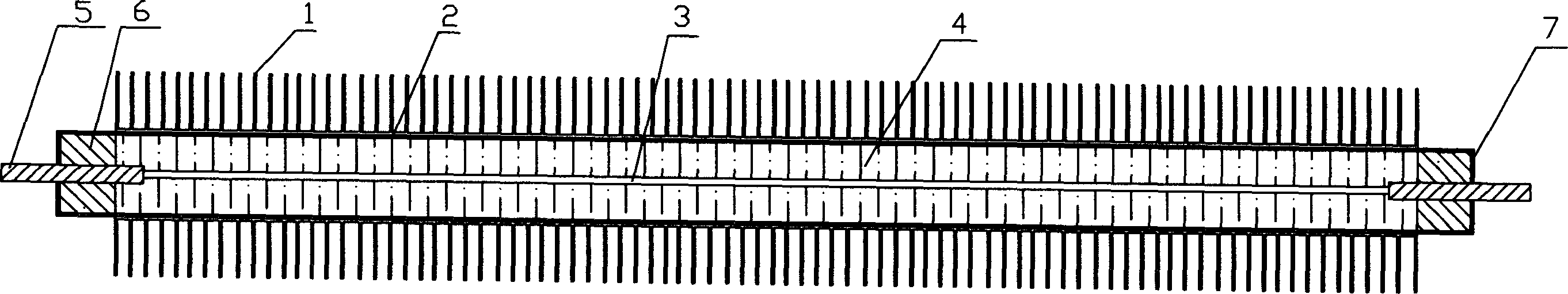

[0017] Such as image 3 As shown, the present invention has a heating tube casing 2 made of a metal tube, in which a heating element 3 is fixed by a fixing frame 6, and power connection terminals 5 are arranged at both ends of the heating tube casing 2, and in the heater casing 2 The shell 2 is filled with insulating material 4, the port of the heater shell 2 is filled with insulating sealant 7, and the outer surface of the heater shell 2 is provided with a finned tube 1, and the lower part of said finned tube 1 is embedded in the heating In the heater shell 2, the finned tube 1 is embedded in the heater shell 2 to a depth of 0.1-0.5 mm.

[0018] During manufacture, heating element 3 is fixed in a heater shell 2 that adopts metal tube to make, and said heating element 3 can adopt nickel-chromium alloy or cermet or resistance wire. The power terminal 5 is drawn out at both ends of the heating tube shell 2 and the port of the heater shell 2 is filled with insulating sealant 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com