Air displacement stepless regulating method for reciprocating-piston compressor

A compressor exhaust, reciprocating piston technology, applied in mechanical equipment, machines/engines, liquid variable-capacity machinery, etc., can solve the problems of weakening amplitude and speeding up the frequency of fluctuations, so as to reduce pressure fluctuations, increase reliability, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] With a speed of 980r / min and a rated displacement of 3m 3 / min single-stage air compressor as an example. Implementing the present invention requires an actuator and a control system that can press open the suction valve, and the control system operates as follows:

[0034] (1) Determine the characteristic parameter N of the actuator, which means that the actuator completes a complete set of actions, including pressing-holding-release, the minimum number of work cycles experienced, so N is determined by the response speed of the specific actuator. The characteristic parameter of the actuator in this embodiment is N=10, so a working unit is composed of 10 working cycles.

[0035] (2) The maximum displacement of the compressor at full load is Qm=3m 3 / min.

[0036] (3) Assume that the actual production required displacement Qr = 2.4m 3 / min, the duty cycle is:

[0037] R%=[Qr / Qm×100]%=[2.4 / 3×100]%=80%

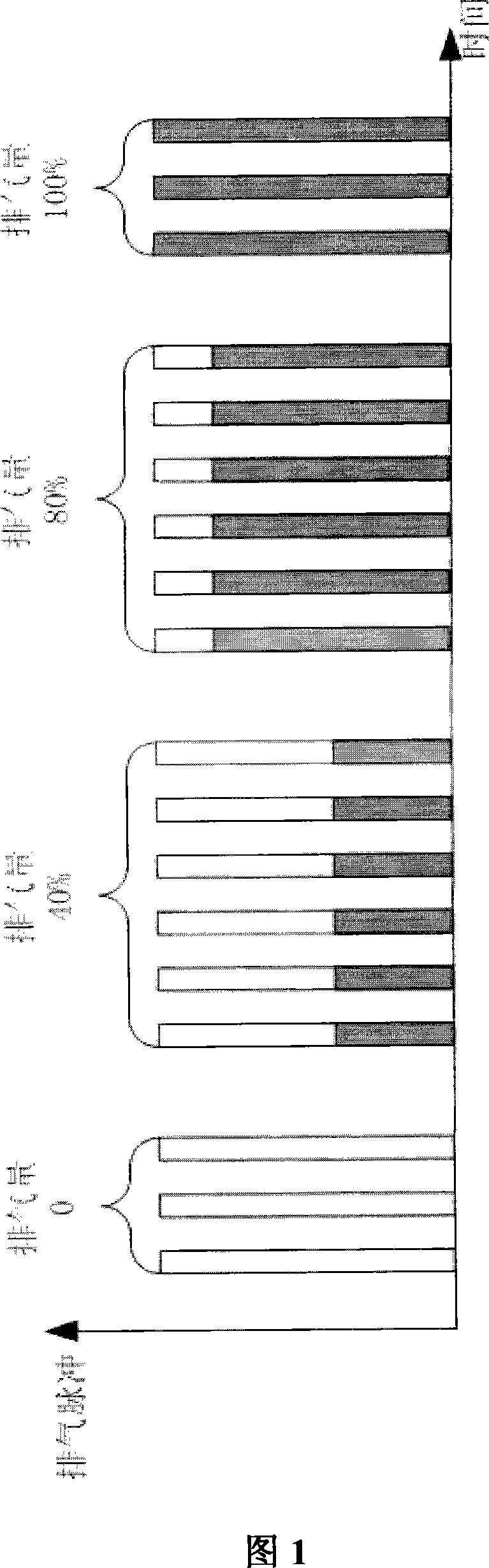

[0038] (4) The actuator operates in the following way: with 100...

Embodiment 2

[0045] In Embodiment 1, 100 working units are taken as a control cycle, and the control cycle can be adjusted when a higher requirement is placed on the uniformity of the exhaust gas. The operation steps are as follows:

[0046] Steps (1), (2) are the same as in Example 1.

[0047] Step (3) still assumes that the actual production exhaust volume Qr=2.4m 3 / min, the duty cycle is:

[0048] R%=[Qr / Qm×100]%=[2.4 / 3×100]%=80%

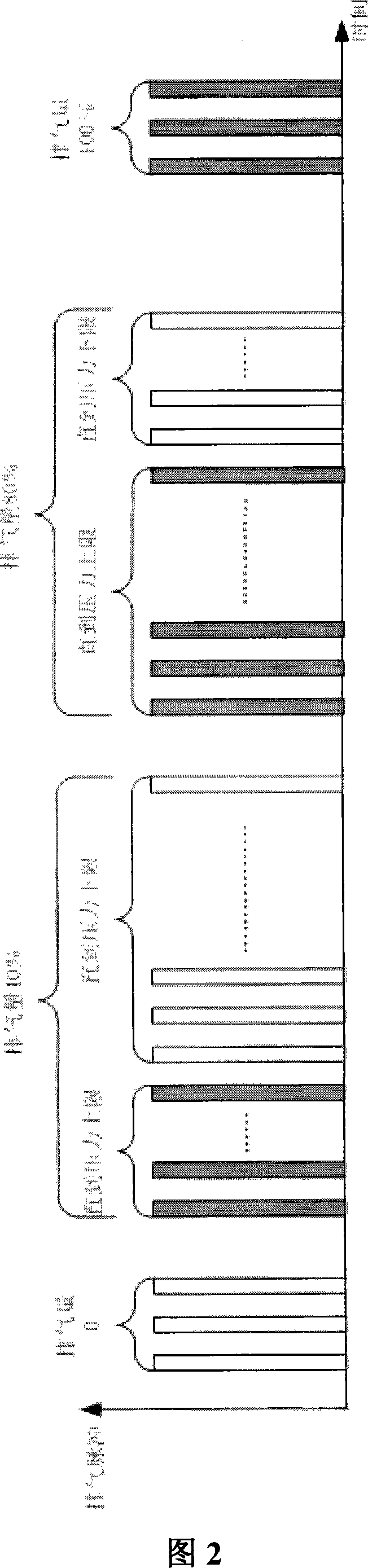

[0049] (4) The actuator operates in the following manner: with 40 work cycles as a control cycle, 32 loading work units are executed first, and then 8 no-load work units are executed; the loading work unit accounts for 80% of the control cycle, and compression The machine still works according to the duty cycle.

[0050] (5) If the gas volume required for production has not changed, repeat the above step (4); if it needs to be changed, perform steps (3) to (4) to calculate with the new required gas volume.

[0051] For example, if the required gas volum...

Embodiment 3

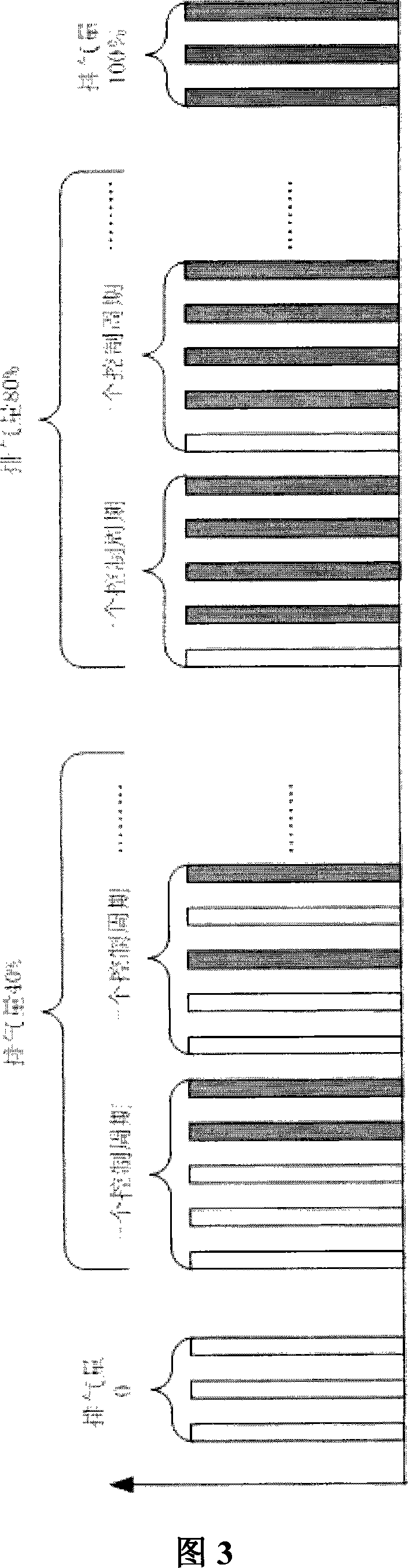

[0056] Take a certain L-13 / 7-250 natural gas compressor as an example, the speed is 740r / min, and the rated displacement is 780m 3 / h, divided into 3 levels, a total of 3 cylinders, which are respectively cylinder 1, cylinder 2 and cylinder 3 according to the process. Implementing the present invention requires a centralized control system, and each of the three cylinders is equipped with an actuator that can press open the suction valve, and the centralized control system operates as follows:

[0057] (1) Determine the characteristic parameters N1, N2, and N3 of each actuator, which means that each actuator independently completes a complete set of actions, including the minimum number of work cycles experienced by pressing-holding-release, so N1~N3 is determined by the specific implementation The agency's speed of response will determine. The characteristic parameters of the actuator in this embodiment are N1=10, N2=20, N3=25.

[0058] (2) The maximum displacement of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com