Time temperature indicator and manufacturing method thereof

A technology for indicating devices, time and temperature, applied in thermometers, measuring devices, thermometers with physical/chemical changes, etc., can solve the problem of inability to meet the timing requirements of time and temperature indicators, the characteristics of micropores in the moving medium layer are not obvious, phase change materials Poor penetration effect and other problems, to avoid failure of time indication function, improve affinity, and good penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

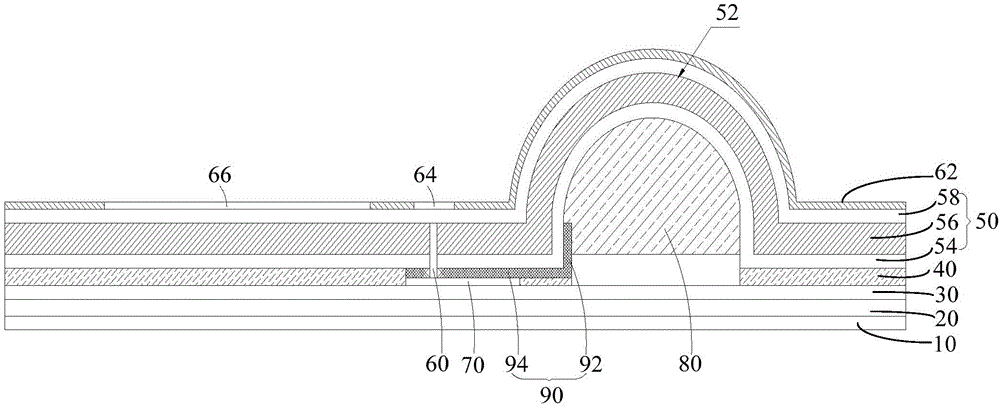

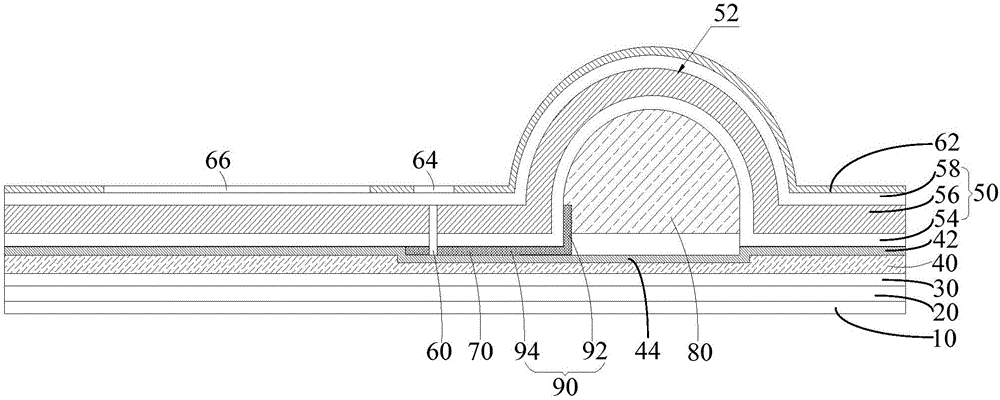

[0072] refer to image 3 , in terms of structure, the structure of the time temperature indicating device of embodiment 1 is the same as image 3 The structure of the embodiment shown in is the same;

[0073] In terms of material, the release layer 10 is release paper; the adhesive layer 20 is acrylic resin; the base layer 30 is aluminum foil; the adhesive layer 40 is hot melt adhesive; the anti-solvent layer 42 is unstretched high-density polyethylene film; the lower interlayer 54 is unstretched high-density polyethylene; the sandwich layer 56 is a medium-density polyethylene filled with white hydrophobic silicon dioxide, and its initial color is white; the upper interlayer 58 is PET; the ink layer 62 is Ink; barrier layer 90 is hot stamping anodized aluminum; phase change material 80 is a mixture of pelargonic acid and No. 4 Sudan Red with a freezing point of 11°C.

[0074] The working principle of the time temperature indicating device is:

[0075] Before pressing to act...

Embodiment 2

[0078] refer to image 3 , in terms of structure, the structure of the time temperature indicating device of embodiment 2 is the same as image 3 The structure of the embodiment shown in is the same;

[0079] In terms of material, the release layer 10 is release paper; the adhesive layer 20 is acrylic resin; the base layer 30 is aluminum foil; the adhesive layer 40 is hot melt adhesive; the anti-solvent layer 42 is BOPP film; the lower interlayer 54 is BOPP film The sandwich layer 56 is medium density polyethylene filled with blue Prussian blue, and its initial color is blue; the upper interlayer 58 is a BOPP film; the ink layer 62 is ink; the barrier layer 90 is paraffin; the phase change material 80 has A mixture of lauryl alcohol and a red oil-soluble dye with a freezing point of 24°C.

[0080] The working principle of the time temperature indicating device is:

[0081] Before pressing to activate, the user can see the initial color (blue) of the sandwich layer 56 throug...

Embodiment 3

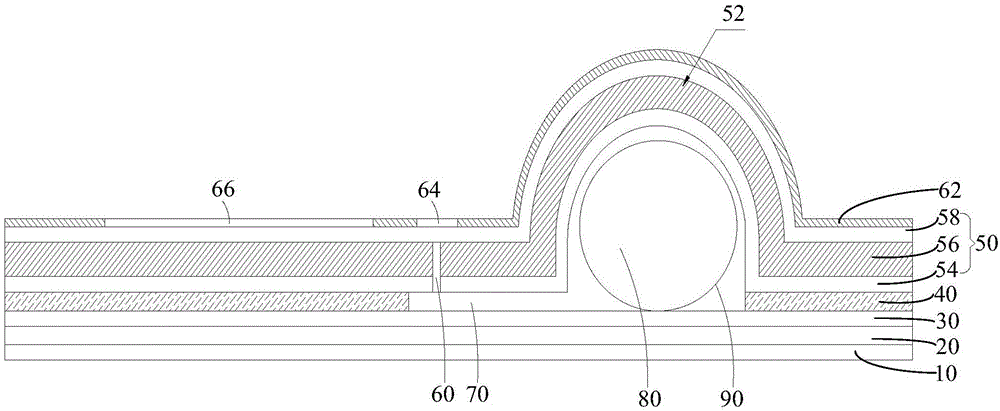

[0084] refer to figure 1 , in terms of structure, the structure of the time temperature indicating device of embodiment 3 is the same as figure 1 The structure of the embodiment shown in is the same;

[0085]In terms of material, the release layer 10 is release paper; the adhesive layer 20 is acrylic resin; the base layer 30 is aluminum foil; Background color, this background color corresponding time display window 66 is set; Lower interlayer 54 is PET; Sandwich layer 56 is the low-density polyethylene that is filled with inorganic pigment, and it is transparent film; Upper interlayer 58 is PET; Ink layer 62 is ink; The barrier layer 90 is silicone; the phase change material 80 is a mixture of lauryl alcohol and yellow oil-soluble dye with a freezing point of 24°C.

[0086] The working principle of the time temperature indicating device is:

[0087] Before pressing and activating, the user can see the printed background color (blue) on the transparent indicating layer 50 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com