Multilayer thin film and its preparation method and time temperature indicating device

A multi-layer thin film and thin film technology, applied in thermometers, measuring devices, chemical instruments and methods, etc., can solve the problems of unable to meet the timing requirements of time and temperature indicators, poor penetration effect of phase change materials, and inconspicuous micropore characteristics, etc. Achieve the effect of firm bonding, good gas-liquid barrier performance, and improved affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

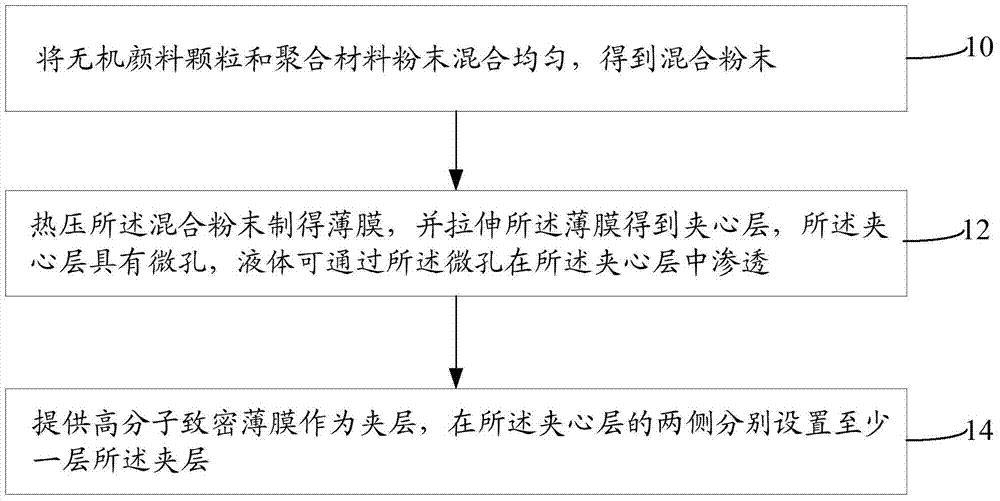

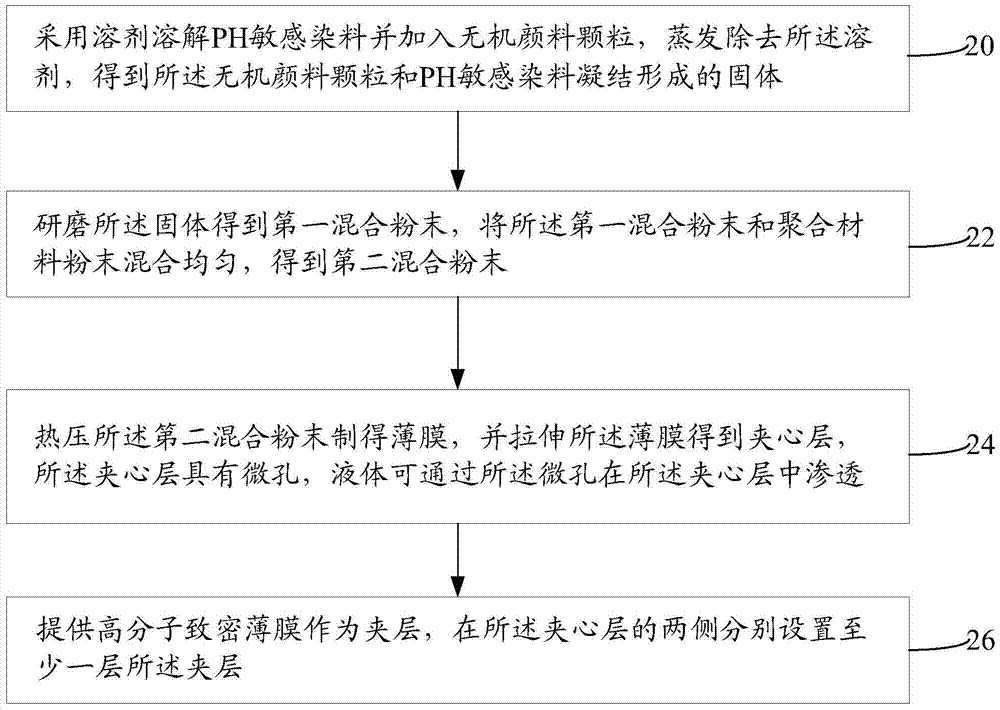

[0039] The invention also provides a method for preparing a multilayer film, with reference to figure 1 In one embodiment, the preparation method of the multilayer film includes:

[0040] Step 10. Mix the inorganic pigment particles and the polymer material powder uniformly to obtain a mixed powder. Among them, the inorganic pigment particles and the polymer material powder are preferably mixed by grinding until the color is uniform.

[0041] Step 12: Hot-press the mixed powder to prepare a film, and stretch the film to obtain a sandwich layer. The sandwich layer has micropores through which liquid can penetrate into the sandwich layer. Among them, hot pressing preferably uses a hot plate to heat the mixed powder in a molten state for 5 minutes under a pressure of 5 tons, and then stretch the film after cooling to a certain extent.

[0042] Step 14. Provide a dense polymer film as an interlayer, and at least one interlayer is provided on both sides of the sandwich layer. Among them...

Embodiment 1

[0054] S1. Provide inorganic pigment particles;

[0055] Select nano-level hydrophobic silica powder as the inorganic pigment particles, and silica has the characteristics of low cost, safety and easy handling.

[0056] S2, prepare the sandwich layer;

[0057] Add 0.4g of hydrophobic nano-silica powder to 2.0~4.0g of low-density polyethylene powder material, grind the above two powders until the color is uniform, and then use a hot plate to grind the ground powder under a pressure of 5 tons. After being hot pressed at ℃ for 5 minutes and cooled to a certain degree, the film was biaxially stretched to prepare a low density polyethylene microporous film with a thickness of 0.1 mm.

[0058] S3. Preparation of multilayer film;

[0059] Select the PET film and BOPP film with a thickness of 15um as the interlayer respectively. According to the sequence of PET film / low density polyethylene microporous film / BOPP film, through co-extrusion or compounding, a white three-layer with a thickness of...

Embodiment 2

[0061] S1. Provide inorganic pigment particles;

[0062] Select nano-level hydrophobic Prussian blue pigment as the inorganic pigment particles.

[0063] S2, prepare the sandwich layer;

[0064] In order to match the hydrophobic inorganic pigment particles, polyethylene with hydrophobic characteristics is selected as the sandwich layer material of this embodiment;

[0065] Add 0.2g of hydrophobic Prussian blue pigment particles to 2.0~4.0g of medium density polyethylene powder material, grind the above two powders until the color is uniform, and then use a hot plate to grind the ground powder at 115°C under a pressure of 5 tons. After hot pressing for 5 minutes and cooling to a certain extent, the film is biaxially stretched to prepare a blue medium density polyethylene microporous film with a thickness of 0.15 mm.

[0066] S3. Preparation of multilayer film;

[0067] The PVC film and LDPE film with a thickness of 15um are respectively selected as the interlayer, according to the order ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com