Method and apparatus for testing spraying characteristic of secondary cooling nozzle of continuous casting

A technology for nozzle spraying and characteristic testing, which is used in the testing of measuring devices, machine/structural components, and fluid pressure measurement. The effect of increasing the degree of automation

Inactive Publication Date: 2006-06-21

CHONGQING UNIV +1

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of this test method is that there are many sensors, large investment, high maintenance work and maintenance costs, and there are also problems that data accuracy and comparability are affected due to errors between the sensors themselves.

[0005] In addition, the existing nozzle water flow density distribution and impact pressure distribution tests are all carried out on two different sets of devices. Whether the determination of the two detection parameters can be completed on the same device and at the same time overcome the shortcomings of the existing detection methods is an important issue of the present invention. Problems to be Solved by Patents

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

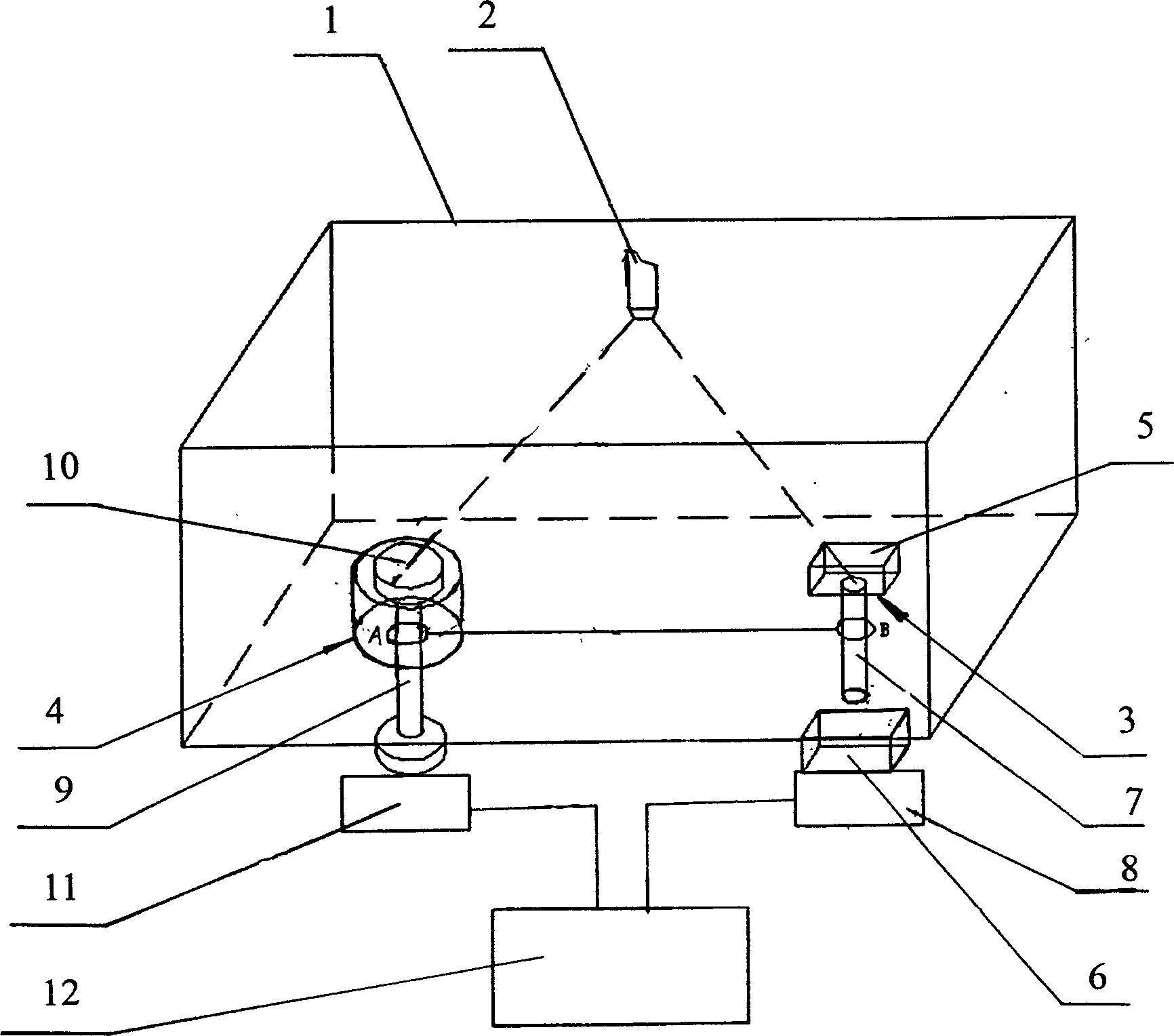

[0029] Embodiment one: below with concrete instrument, test method etc. describe in detail (referring to figure 1 )

[0030] The basic configuration of the present invention is selected as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

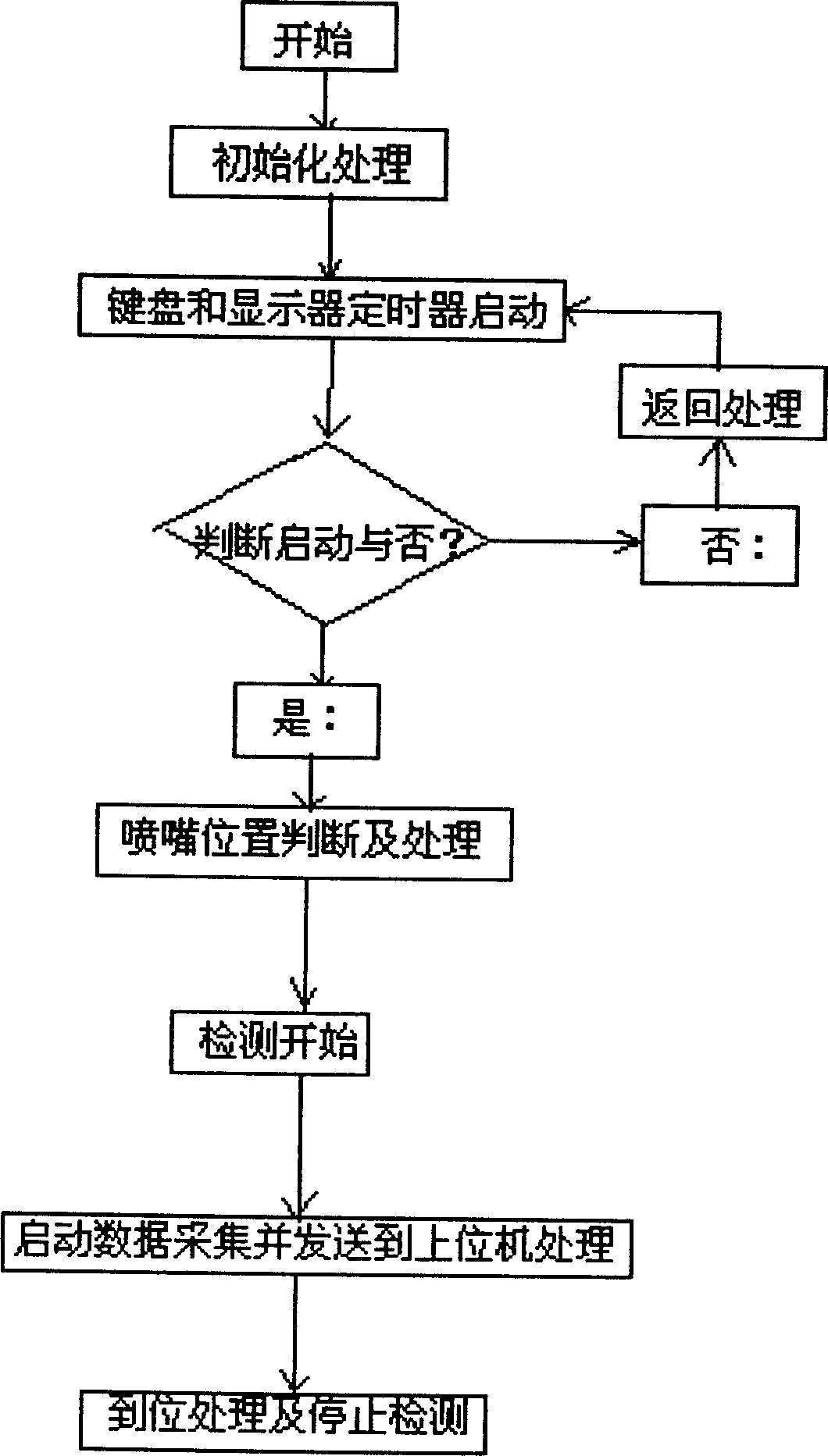

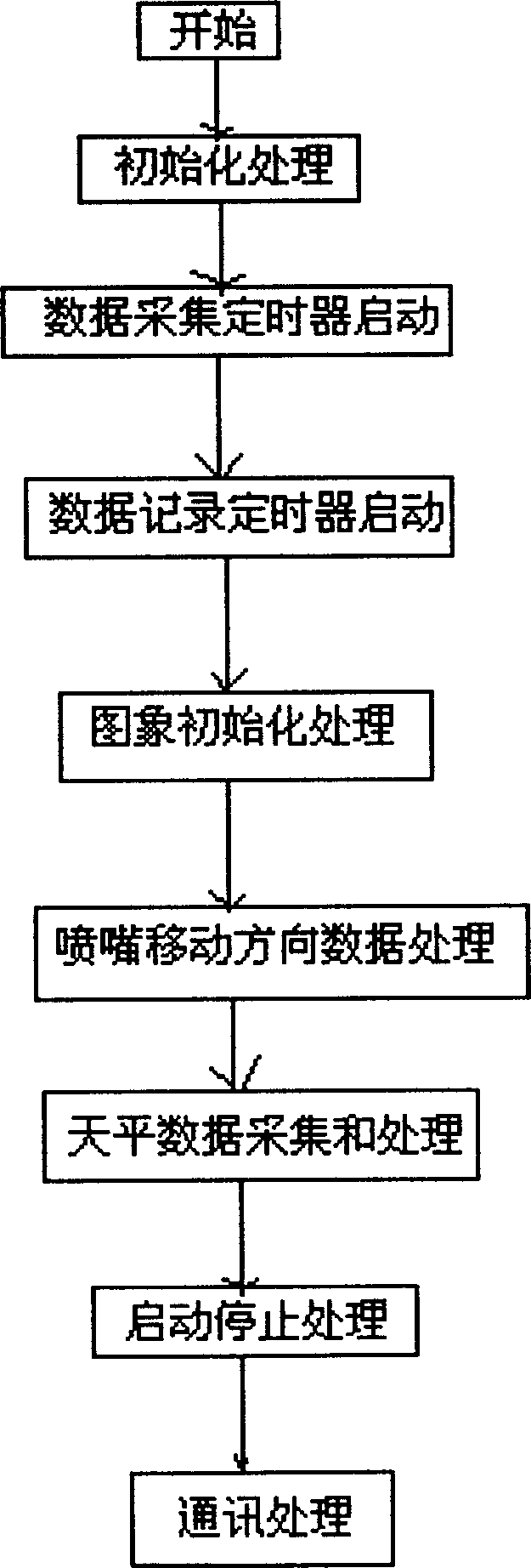

The invention discloses a spray character test method and device of continuous casting two-cold-sprayer, which comprise the following steps: 1. the moving sprayer sprays water through the water-spray quality sensor and water-spray bunch pressure sensor on the downward moving gathering point; 2. the water-spray quality sensor and water-spray bunch pressure sensor transmits the real-time gathered spray quantity and increment and spray bunch pressure value to the computer; 3. the computer calculates the flow density value and bunch pressure value according to the setting parameter and program, which generates the distribution graph of spray flow density and bunch pressure. The entire course can be controlled by computer automatically, which improves the automatic degree greatly to finish the test by one person. The test result can be printed at the report pattern, which displays the distribution graph of spray flow density and bunch pressure.

Description

technical field [0001] The invention relates to a performance detection method and a detection device of a continuous casting secondary cooling nozzle, which is suitable for detecting the water flow density distribution and impact pressure distribution characteristics of the air-water nozzle spray of the continuous casting secondary cooling nozzle. Background technique [0002] The continuous steel casting process is the cooling and solidification process of molten steel. It is a heat transfer process that takes away the superheat, solidification latent heat and waste heat of liquid steel in a suitable way to solidify molten steel into solid steel; The main measure is to take the above three kinds of heat away through external water cooling. In the cooling and solidification process of the continuous casting slab, the cooling and solidification in the secondary cooling zone is the central link of the slab solidification. Among the various heat transfer methods in the second...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M99/00G01L7/00G01L9/00G01N15/00

Inventor 文光华施金良唐萍贾碧

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com