Engine hole type oil nozzle single-hole extruding and grinding device and use method

A technology for grinding devices and fuel injectors, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve the problem of inability to repair and evaluate the shape and structure of a single nozzle hole, and the inability to uniform flow rate of a single nozzle hole Performance testing and other issues to achieve the effects of reducing fuel consumption and harmful gas emissions, improving combustion and emission processes, and improving mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

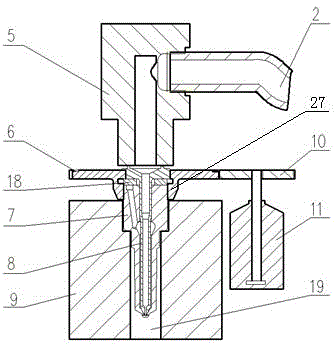

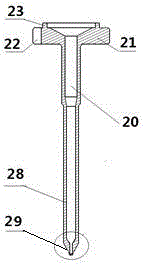

[0038] The fuel injector body 7 to be ground in the present invention is a prior art, and the fuel injector body 7 is fixed on the nozzle seat 9 with an emptying pipeline 19 inside. Such as Image 6 with Figure 7As shown, the bottom of the injector body 7 is provided with several injector holes 26 . The spray holes 26 of the fuel injectors may be arranged in a single layer uniformly distributed along the axial direction, or distributed in a single layer but with different inclination angles, or distributed in multiple layers. The single-hole squeezing and grinding device of the engine hole type fuel injector of the present invention is applicable to all above-mentioned arrangement modes of the spray hole 26 of the fuel injector.

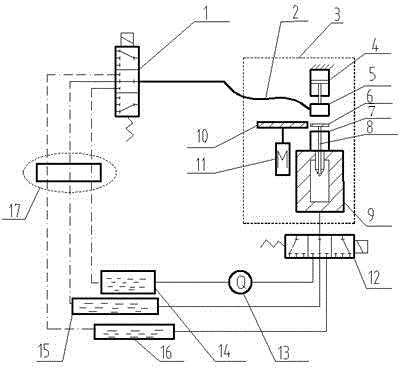

[0039] Such as figure 1 As shown, a single-hole squeezing and grinding device for an engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com