Coating device for researching vacuum spraying characteristics

A vacuum spraying and coating device technology, applied in the direction of spray discharge device, injection device, measuring device, etc., can solve the problems that it is difficult to prepare functionally gradient thin films and laminated films, the structure of testing instruments is complicated, and it is difficult to popularize and apply. Achieve the effects of small footprint, simple structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

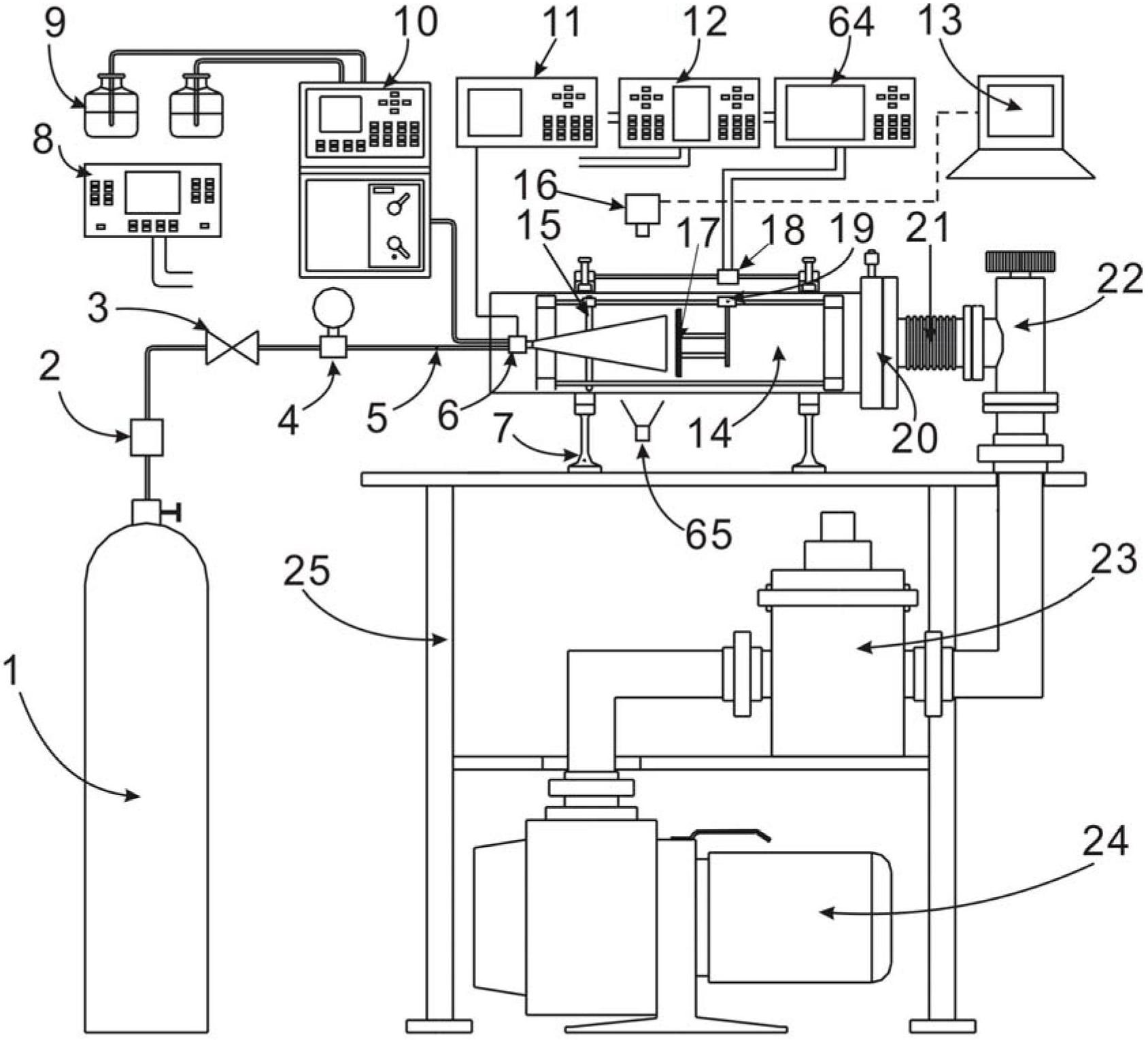

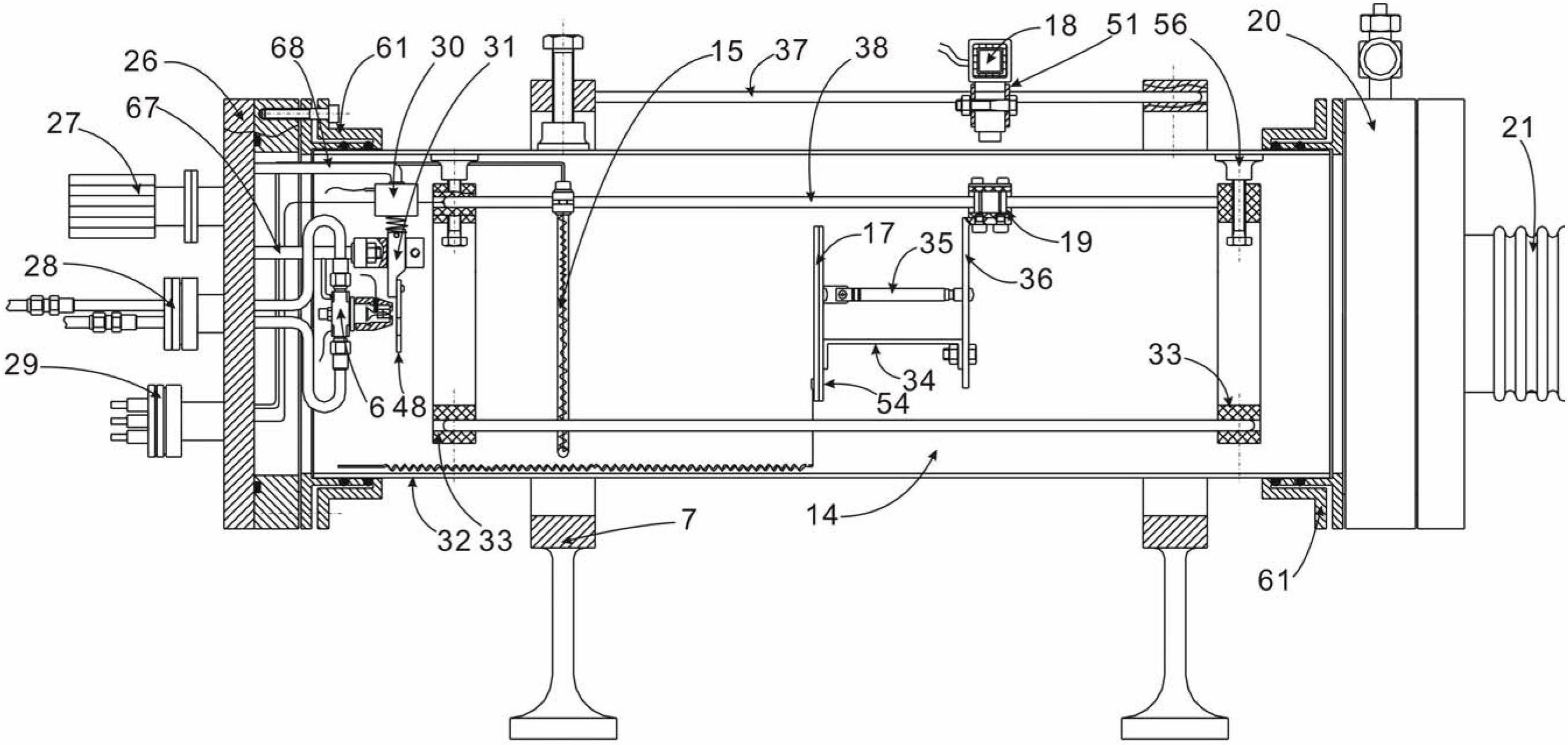

[0055] Embodiment 1: spray characteristics research

[0056] The above-mentioned coating device can adjust the atomization cone angle, spraying angle and spraying temperature under different conditions such as polymer concentration, gas-liquid flow ratio (pressure ratio), nozzle diameter, vacuum spray chamber pressure and temperature, distance between atomizing nozzle and substrate, substrate temperature, etc. The atomization characteristics such as beam width, jet penetration distance, rupture length, atomization velocity, droplet number density, droplet size and distribution are studied, and the influence of each spray parameter on the film forming quality is analyzed according to the atomization characteristics. The study of spray characteristics requires only an atomizing nozzle and a beaker filled with a polymer solution of known concentration and connected to the atomizing nozzle through a liquid chromatography pump. First, after completing step (1), replace the correspo...

Embodiment 2

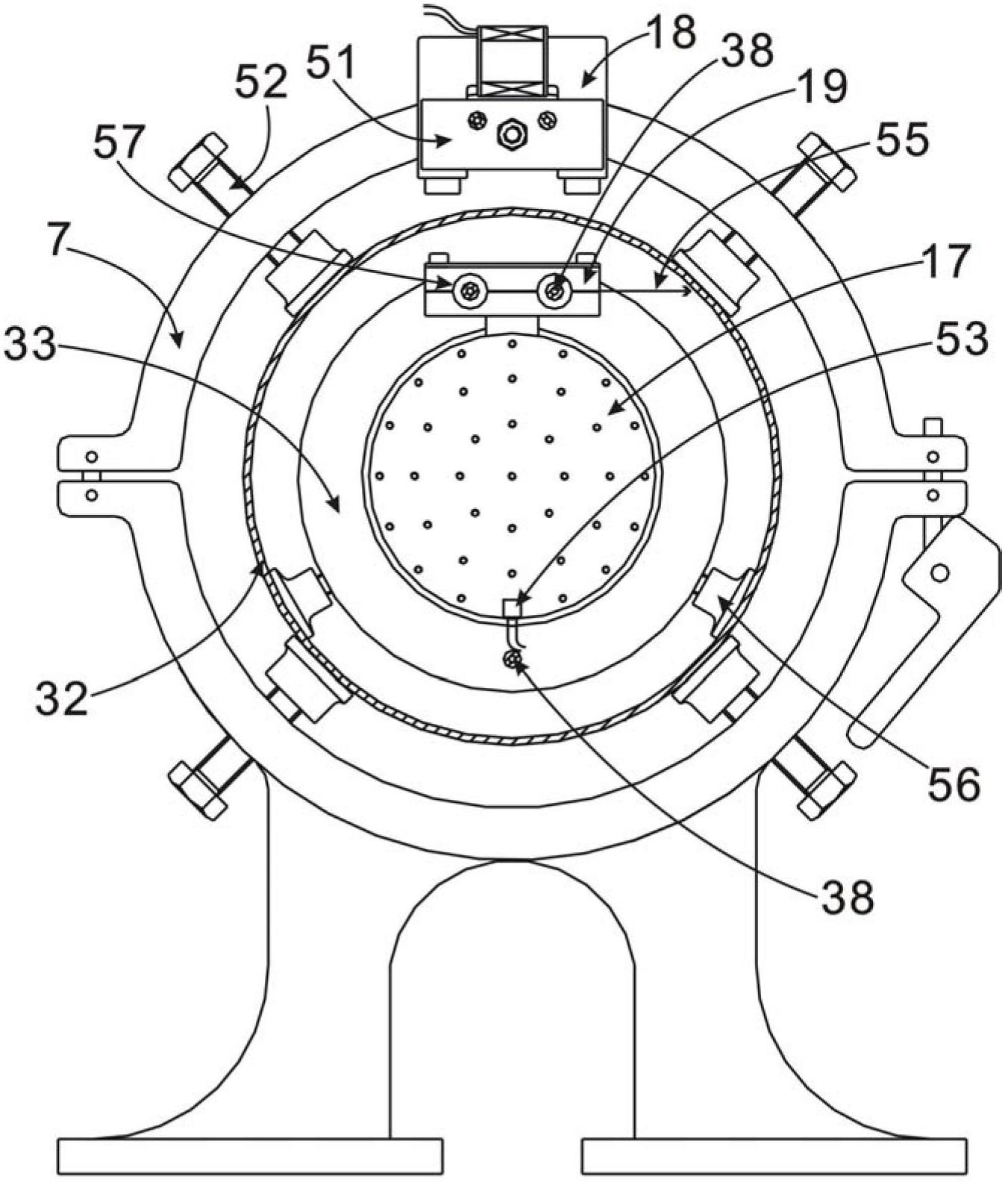

[0058] Embodiment 2: Preparation of polymer functionally gradient film

[0059] The preparation of functionally graded films requires only one atomizing nozzle and two beakers filled with different polymer solutions. After completing the above steps (1) and (2), first, adjust the electropermanent magnet on the outer guide rail of the spray chamber fixing frame to the set position, and the distance between the atomizing nozzle and the substrate holder can be determined by the position indicated by the scale; Secondly, carry out test spraying according to step (3). In the case of ensuring the spraying effect, program the HPLC liquid chromatography pump according to the experimental requirements, mix the two polymer solutions according to a certain concentration ratio, and transport them to Atomizing nozzle; then, turn on the controller of the heating device to make the infrared heating tube and the silicone rubber heater work, the temperature of the substrate is transmitted to t...

Embodiment 3

[0060] Embodiment 3: preparation of polymer laminated film

[0061] The preparation of the polymer laminated film requires two atomizing nozzles and two beakers, and the two beakers are filled with different polymer solutions, which are respectively fed into different HPLC liquid chromatography pumps. After completing the above steps (1) and (2), firstly, adjust the electropermanent magnet to the set position, and the distance between the atomizing nozzle and the substrate is determined by the position indicated by the scale; secondly, perform test spraying according to step (3) , in the case of maintaining the spraying effect, program the HPLC liquid chromatography pump as required to realize spraying of different polymer solutions from different atomizing nozzles in different time periods; then, turn on and adjust the controller of the heating device to make the injection process The temperature and the temperature of the substrate reach the experimental set value; finally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com