Grubbing anchoring integrative grub-anchor winch

A technology of bolter and bolter, which is applied in the direction of cutting machinery, earth drilling and mining, etc. It can solve the problems of high labor intensity of manual bolting, reduce the work intensity of the operator, and waste time, so as to improve the rigidity and increase the Function, the effect of reducing the size of the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

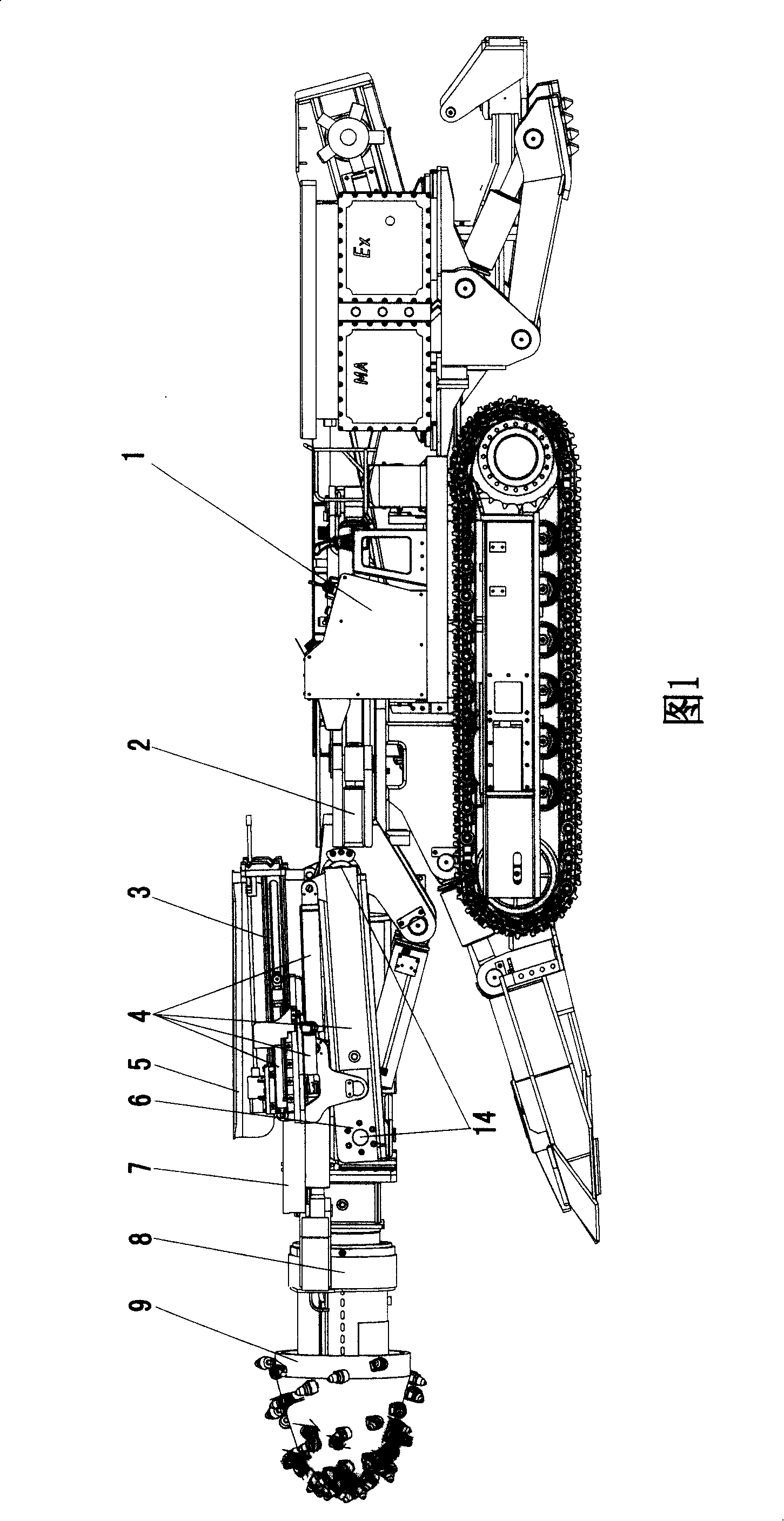

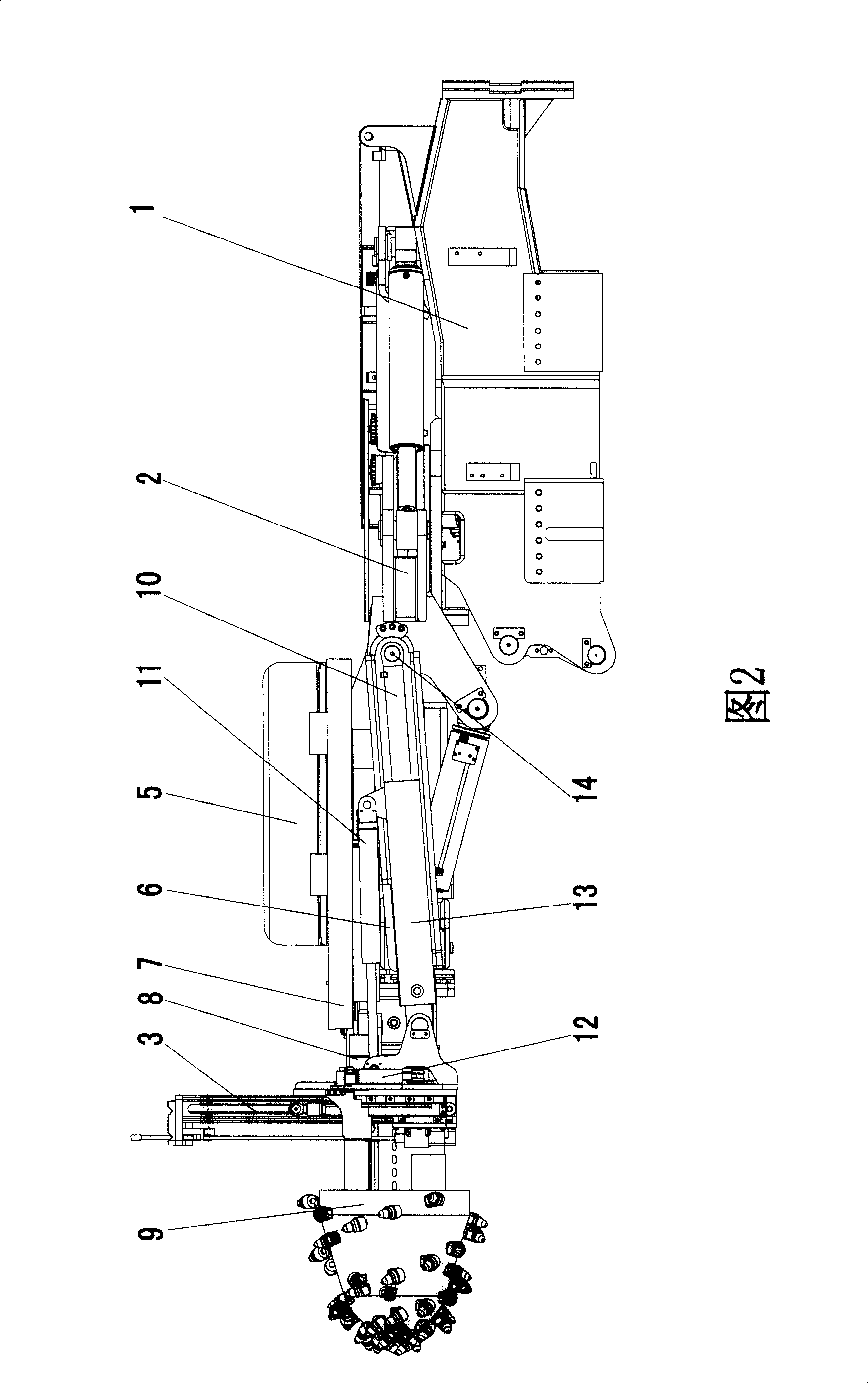

[0042] As shown in Fig. 1 and Fig. 2, the present invention is a bolter digging machine integrated with digging and bolting. The bolter miner is an integrated installation structure of a tunneling machine 1 and a bolter 3, and the bolter 3 is installed on the side of the cutting part 8. The bolter 3 is connected with the boring machine 1 through a rail 6 . In the figure, the cutting part 8 on the roadheader can rotate with the slewing table 2, the upper part of the cutting part 8 is provided with a cutting part guard plate 7, and the parts on both sides of the cutting part 8 are bolts with bolter guard plates 5 machine device, it performs lifting and swinging motion together with the cutting part 8 of the roadheader 1, plus the action function of its own hydraulic cylinder 4 (including: telescopic cylinder 10, vertical cylinder 11, rotating cylinder 12, etc.), to complete the roadway anchor Rod anchoring work.

[0043] In the working state of the bolter as shown in Figure 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com