Labeling and marking method for inner wall of tube core

A tube core and labeling technology, applied in labeling machine, labeling, labeling and other directions, can solve the problems of high production cost and low work efficiency, and achieve the effect of improving efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

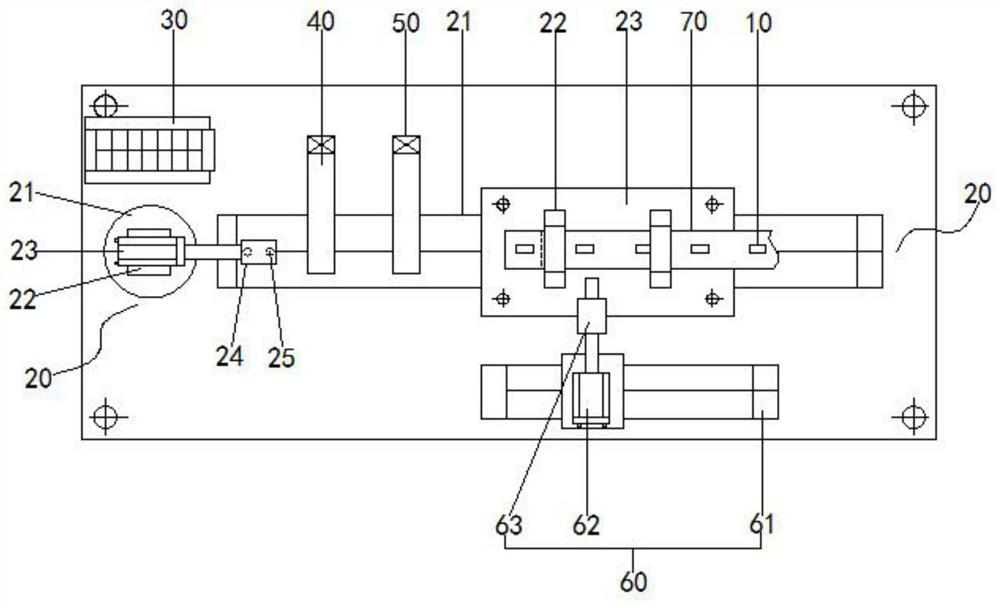

[0024] refer to Figure 1-3 , the method for labeling and marking the inner wall of the tube core specifically includes the following steps,

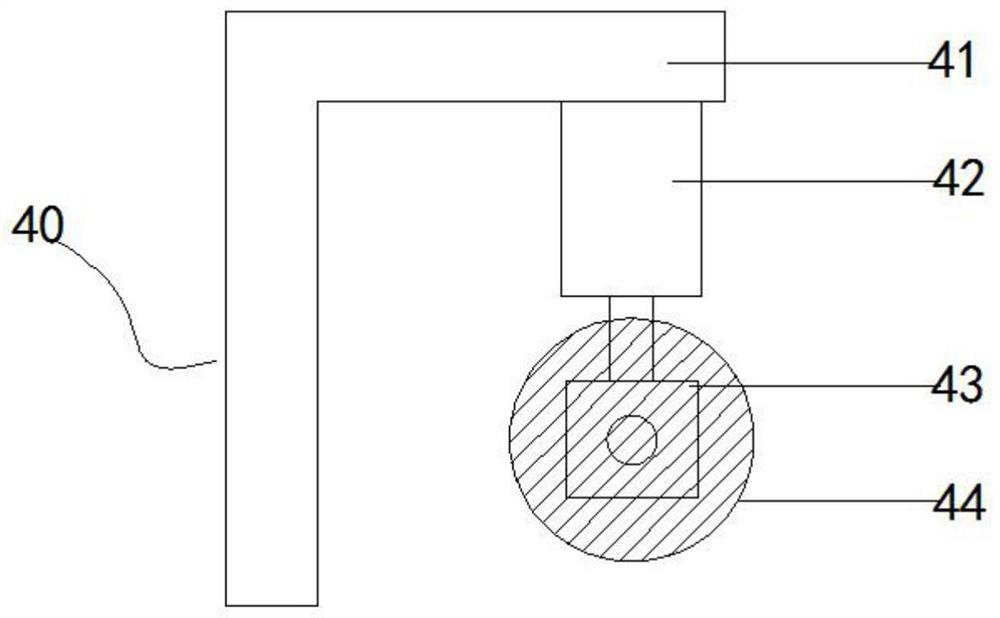

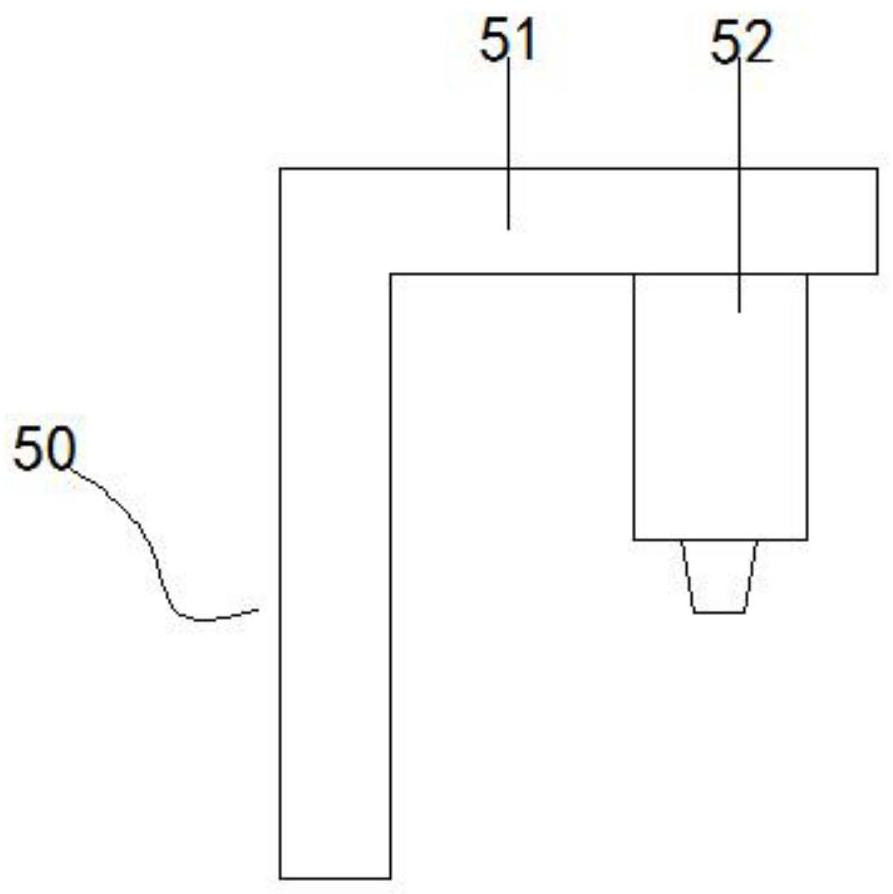

[0025] Step 1, place the tube core 70 with the avoidance holes 10 equidistantly formed on the upper surface on the reciprocating feeding device 20 (in use, the tube core referred to here can be made of PE / PP / PA / PA material tube core), and a labeling manipulator is provided at the conveying end of the reciprocating feeding device, and a die cutting machine 40 and a laser marking machine 50 are provided at the rear of one end of the reciprocating feeding device, and a labeling manipulator is provided at the rear of the labeling manipulator A label stripper 30 is provided (the label glassware is a known technology, and the present invention will not go into details here), and a die pulling and pulling device 60 is provided at the front of one end of the reciprocating feeding device;

[0026] Step 3, the reciprocating feeding device sends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com