Moisture-resistant double-drawing polypropylene pearl label base film and preparation method thereof

A double-drawn polypropylene, polypropylene technology, applied in the directions of labels, chemical instruments and methods, flat products, etc., can solve problems such as label collapse, and achieve the effect of good moisture resistance and good moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The moisture-resistant double-drawn polypropylene pearl label base film of the present embodiment and its preparation method are as follows:

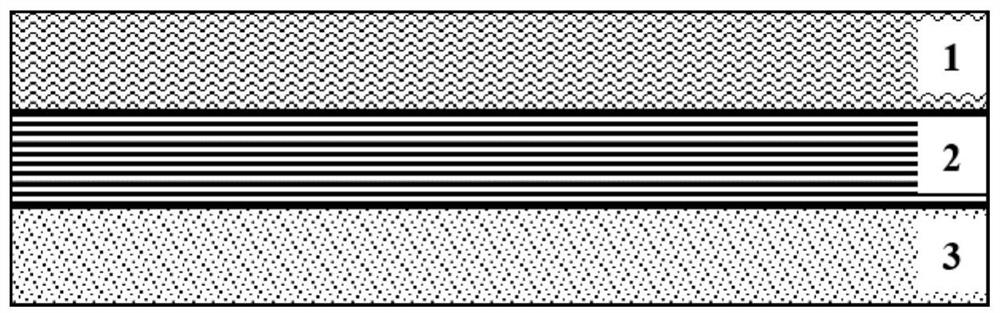

[0047] The moisture-proof double-drawing polypropylene pearl label base film of the present embodiment is as follows: figure 1 shown.

[0048] (1) Prepare raw materials:

[0049] The first surface layer 1: get 75wt% through twin-screw blending process and the resin of granulation (the resin comprises high-density polyethylene, ethylene propylene butene terpolymer, high density polyethylene, ethylene propylene butene terpolymer The weight ratio of the product is 45:55, wherein the melt index of HDPE is 0.03g / 10min, the MFR of ethylene propylene butene copolymer is 7g / 10min), 25wt% ethylene norbornene copolymer (Nippon Polyplastics 8007F, Tg 78℃, MVR is 1cm 3 / 10min) and mix evenly to obtain the first surface layer 1 resin.

[0050] Core layer 2: take 86.5wt% L5D98C polypropylene resin (manufacturer is China National Petroleum ...

Embodiment 2

[0055] The moisture-resistant double-drawn polypropylene pearl label base film of the present embodiment and its preparation method are as follows:

[0056] The moisture-proof double-drawing polypropylene pearl label base film of the present embodiment is as follows: figure 1 shown.

[0057] (1) Prepare raw materials:

[0058] The first surface layer 1, the second surface layer 3: take 70wt% respectively through the twin-screw blending processing and granulated resin (the resin includes high-density polyethylene, ethylene propylene butene terpolymer, high-density polyethylene, ethylene Propylene butene terpolymer wherein the weight ratio is 45:55, wherein the melt index of HDPE is 0.03g / 10min, the MFR of ethylene propylene butene copolymer is 7g / 10min), 30wt% ethylene norbornene copolymer ( Polyplastics 9056F, Tg is 65°C, MVR is 1cm 3 / 10min), and mix evenly to obtain the first surface layer 1 and the second surface layer 3 resins with the same formulation.

[0059] Core l...

Embodiment 3

[0063] The moisture-resistant double-drawn polypropylene pearl label base film of the present embodiment and its preparation method are as follows:

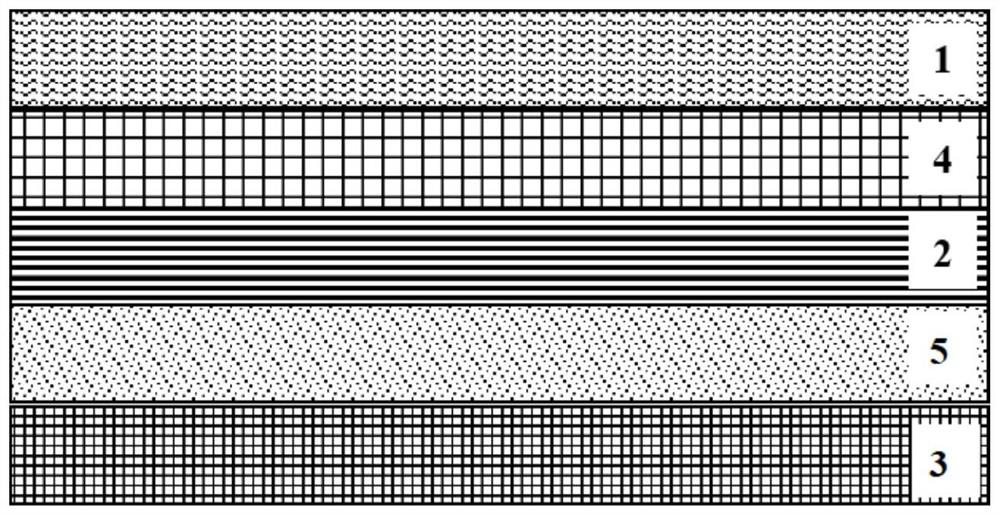

[0064] The moisture-proof double-drawing polypropylene pearl label base film of the present embodiment is as follows: image 3 shown.

[0065] (1) Prepare raw materials:

[0066] The first surface layer 1: take 65wt% of the resin (the resin includes high-density polyethylene, ethylene propylene butene terpolymer, high density polyethylene, ethylene propylene butene terpolymer) through twin-screw blending and granulation The weight ratio of the product is 45:55, wherein the melt index of HDPE is 0.03g / 10min, the MFR of ethylene propylene butene copolymer is 7g / 10min), 35wt% of the ethylene norbornene copolymer (Baoli Japan 8007F , Tg is 78℃, MVR is 1cm 3 / 10min), and mix evenly to obtain the first surface layer 1 resin.

[0067] Core layer 2: take 78.5wt% L5D98C polypropylene resin (the manufacturer is China National Petroleum C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com