Black tea making device for food processing

A production device and food processing technology, applied in food forming, application, food science, etc., can solve the problems of slow work progress, easy delay of production progress, increased labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

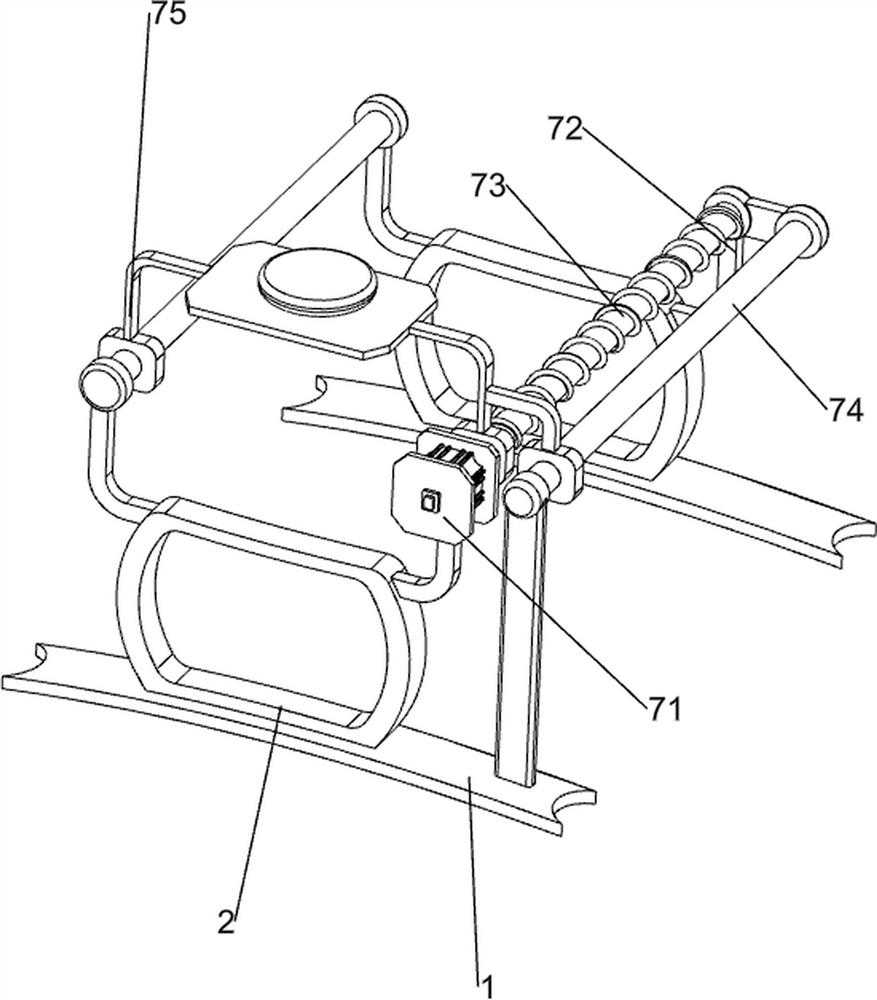

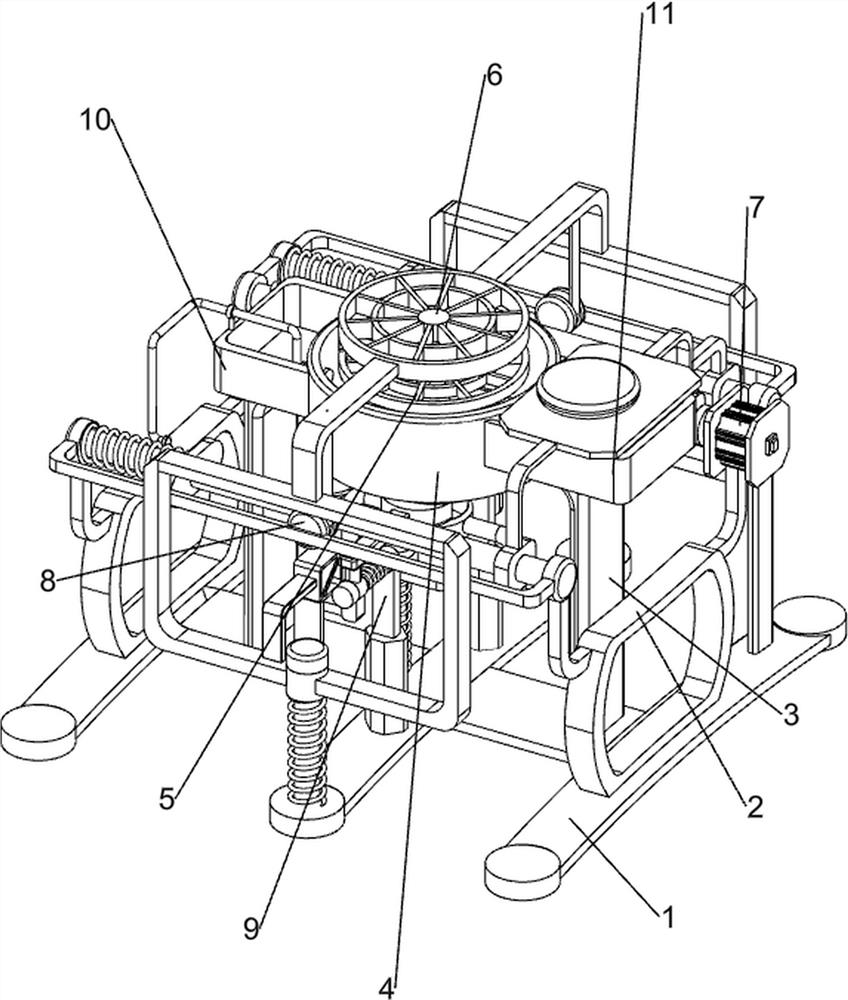

[0069] like Figure 1-4 As shown, a food processing device for black tea production includes a support base plate 1, a support block 2, a support column 3, a working barrel 4, a feeding mechanism 5, a pressing mechanism 6 and a material pushing mechanism 7, and the support base plate 1 is The left and right sides are all provided with supporting blocks 2, the left and right sides on the supporting base plate 1 are all provided with supporting columns 3, a working bucket 4 is arranged between the two supporting columns 3 tops, and a feeding mechanism 5 is arranged on the supporting base plate 1, and the lower The material mechanism 5 passes through the working bucket 4, and a material pressing mechanism 6 is provided in the middle of the support base plate 1, and a material pushing mechanism 7 is provided between the support base plate 1 and the support block 2.

[0070] The unloading mechanism 5 includes a first connecting rod 51, a first sliding plate 52, a first spring 53 an...

Embodiment 2

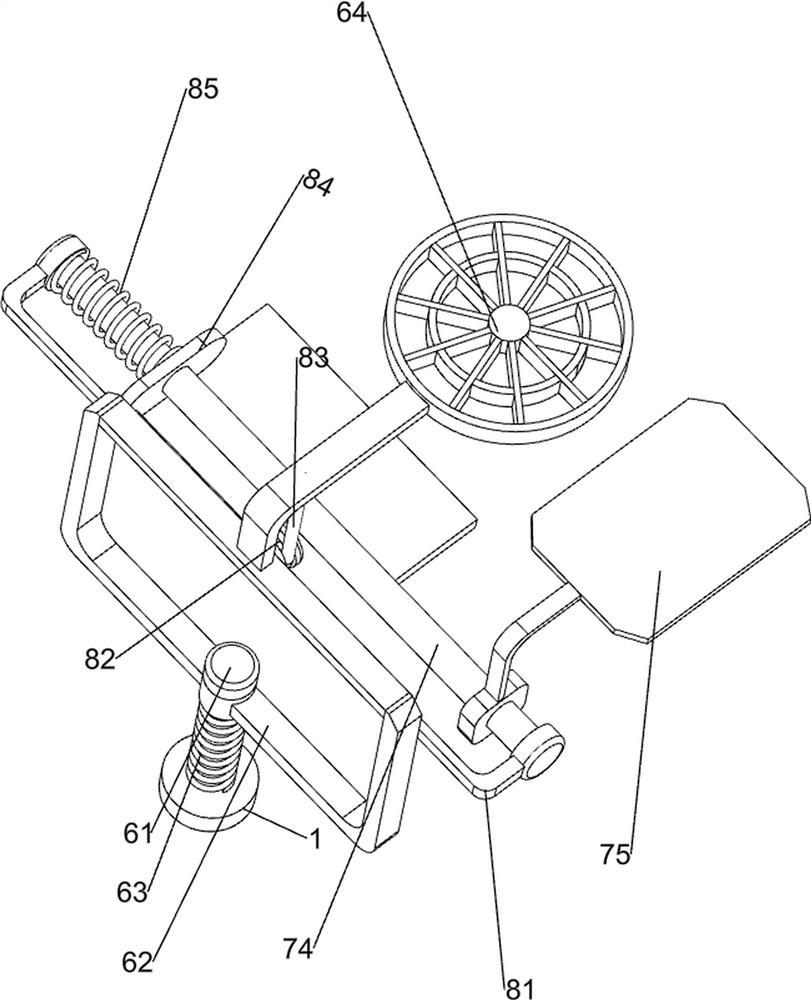

[0078] like figure 1 and Figure 5-8 Shown, also comprise automatic driving mechanism 8, and automatic driving mechanism 8 includes the 4th connecting rod 81, reel 82, stay cord 83, moving plate 84 and the 3rd spring 85, two slide bars 74 outer sides are all provided with The fourth connecting rod 81, the middle inner side of two fourth connecting rods 81 is provided with a reel 82, and the left side of the two slide bars 74 is slidingly provided with a moving plate 84, and the outer sides of the right part of the two moving plates 84 are respectively connected with the same The second sliding plate 62 on the side is connected with a stay cord 83, and the stay cord 83 is slidably connected with the reel 82 on the same side, and the left side of the two slide bars 74 is wound with a third spring 85, and the two ends of the third spring 85 are respectively It is connected with the moving plate 84 and the slide bar 74.

[0079] Also includes a discharge mechanism 9, the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com