A slitting line auxiliary cutting processing device

A processing device and slitting line technology, which is applied in woodworking safety devices, forming/shaping machines, springs/shock absorbers, etc., can solve the problems of large cutting errors of plank deviation and great danger to operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

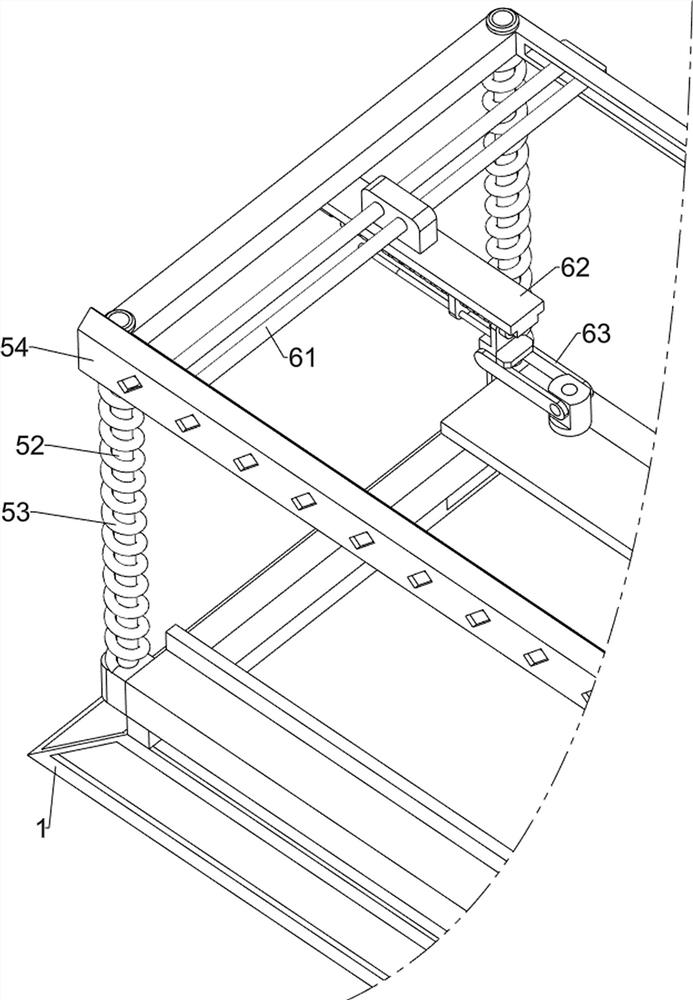

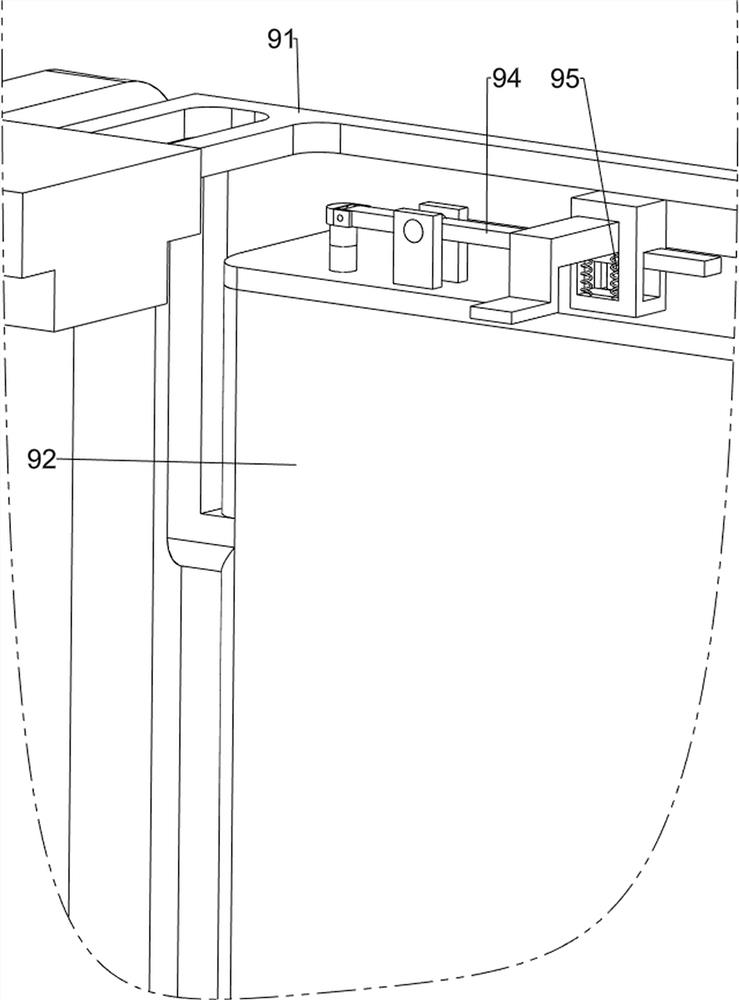

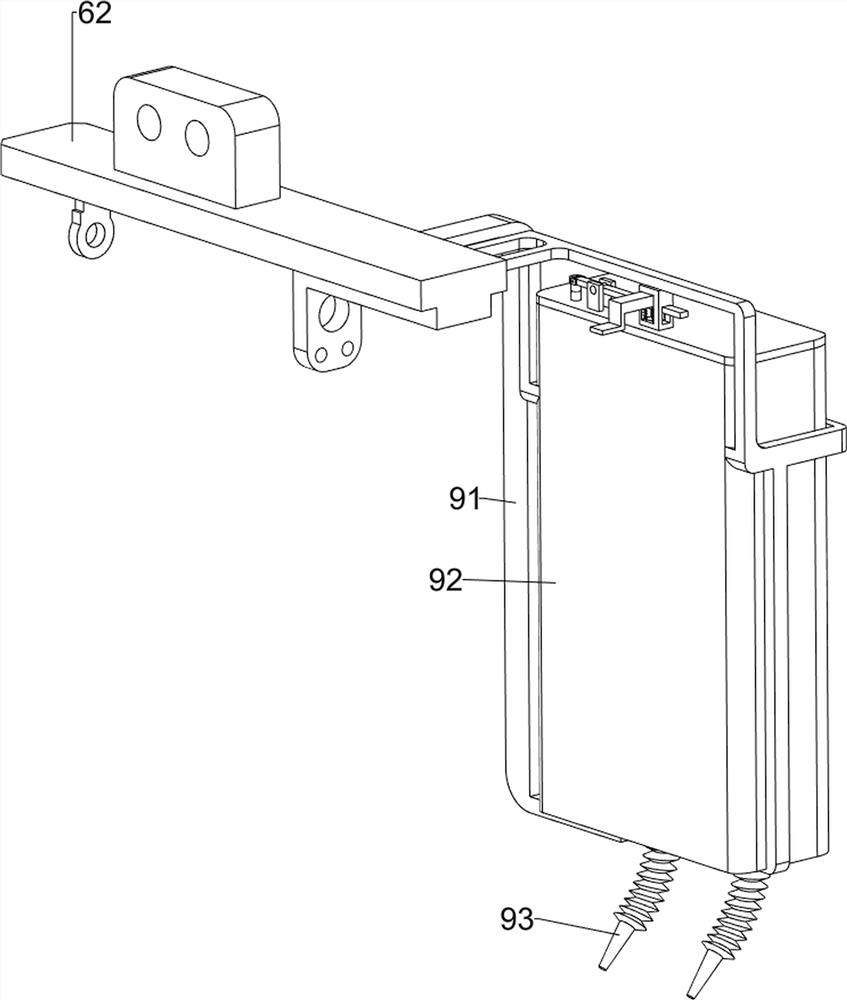

[0078] A slitting line auxiliary cutting processing device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 15 As shown, it includes a support frame 1, a motor 2, a cutting knife 3, a clamping mechanism 4, a lifting mechanism 5, a distance adjustment mechanism 6, a cutting angle adjustment mechanism 7 and a damping mechanism 10. The support frame 1 is provided with a clamping mechanism 4. The top of the support frame 1 is provided with a lifting mechanism 5. The lifting mechanism 5 cooperates with the clamping mechanism 4. The lifting mechanism 5 is provided with a distance adjusting mechanism 6. 7 is provided with a damping mechanism 10, the damping mechanism 10 cooperates with the distance adjusting mechanism 6, the damping mechanism 10 is provided with a motor 2, the motor 2 cooperates with the angle-cutting adjusting mechanism 7, and the right end of the output shaft of the mot...

Embodiment 2

[0091] On the basis of Example 1, as figure 1 , figure 2 , image 3 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, it also includes a pressing mechanism 8. The pressing mechanism 8 includes a fixed frame 81, a moving frame 82, a fourth spring 83, a rack rod 84, a fifth spring 85 and a gear rod 86. The front of the second sliding frame 62 A fixed frame 81 is provided on the left side of the front part, and a movable frame 82 is slidably provided on the rear side of the fixed frame 81. A fourth spring 83 is wound around the movable frame 82. The top of the fixed frame 81 is slidably provided with a rack rod 84 , the rear end of the rack rod 84 is in contact with the moving frame 82 , and a fifth spring 85 is connected between the middle of the rack rod 84 and the fixed frame 81 . The side-rotating type is provided with a gear rod 86 , the gear rod 86 meshes with the rack rod 84 , and the gear rod 86 cooperates with the connecting shaft 75 .

[0092] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com