Downward-pressing type clay tile forming device

A molding device and clay technology, applied in the direction of unloading device, molding head, ceramic molding machine, etc., can solve the problems of unsafe, labor-intensive pressing down and cutting and modifying, etc., and achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

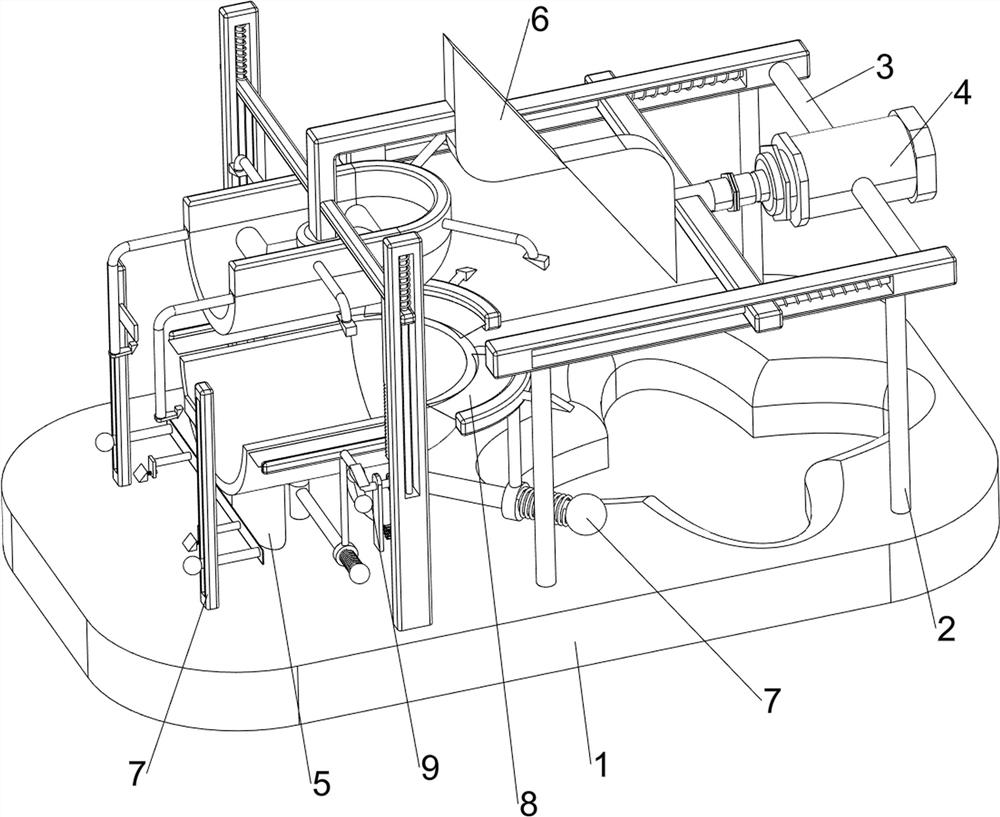

[0024] A press-down clay tile forming device, such as figure 1 As shown, it includes a base 1, a support column 2, a first connection block 3, a cylinder 4, a mold 5 and a pressing mechanism 6, two support columns 2 are arranged on the front and rear sides of the base 1, and the left side of the base 1 is provided with There is a mold 5, a pressing mechanism 6 is provided between the tops of the four supporting columns 2 and on the left side of the base 1, the right side of the pressing mechanism 6 is connected with a first connecting block 3, and the middle part of the first connecting block 3 is equipped with a cylinder 4, The cylinder 4 is connected with the pressing mechanism 6 .

[0025] When people need to shape clay tiles, they can use this molding device. First, people put the clay into the mold 5, then open the cylinder 4, and the cylinder 4 drives the pressing mechanism 6 to press down the clay. After molding, people take off the mold. The clay tile is manually modi...

Embodiment 2

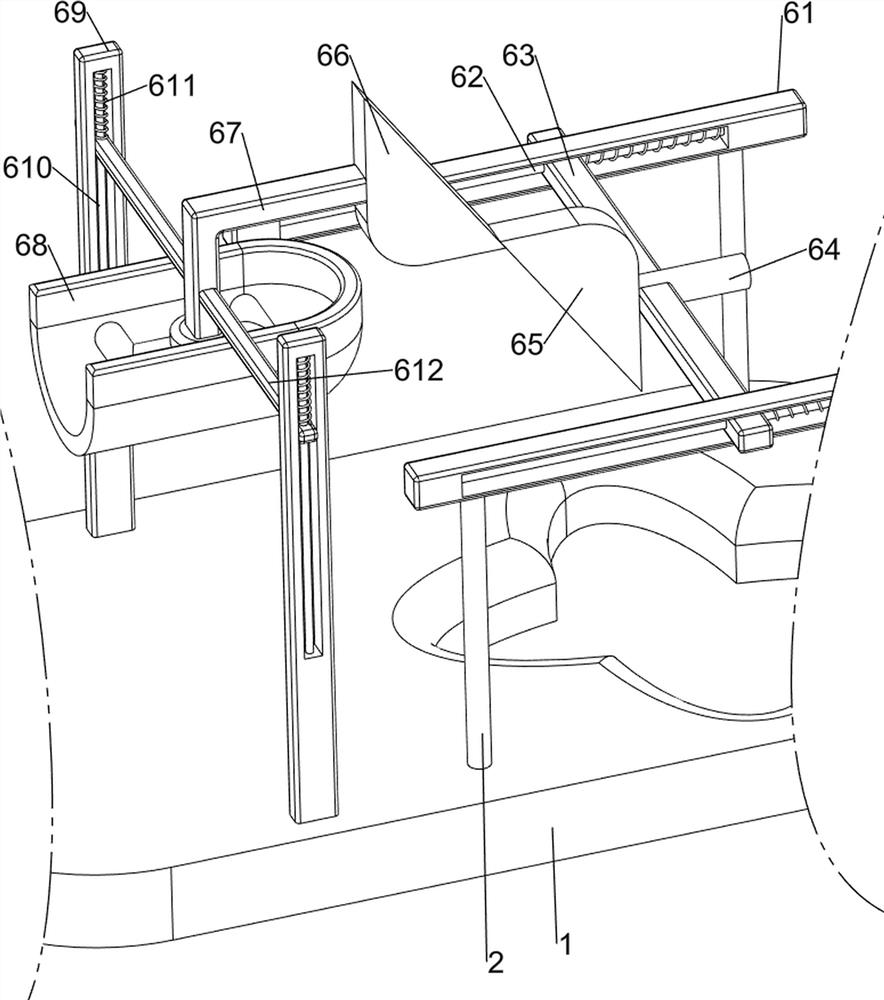

[0027] On the basis of Example 1, such as figure 2 As shown, the pressing mechanism 6 includes a first guide rail 61, a first guide rod 62, a first slide block 63, a second connecting block 64, a first wedge block 65, a second wedge block 66, a third connecting block 67, Press block 68, the second guide rail 69, the second guide bar 610, the first spring 611 and the second slide block 612, are connected with the first guide rail 61 between the tops of the two support columns 2 on the front and rear sides, the two first The right side of the guide rail 61 is connected by the first connecting block 3, and the first guide rod 62 is provided in the two first guide rails 61, and the first slide block 63 is slidably connected between the two first guide rods 62. The middle part of the block 63 is provided with a second connecting block 64, and the left part of the second connecting block 64 is provided with a first wedge-shaped block 65, and the left and right sides of the base 1 a...

Embodiment 3

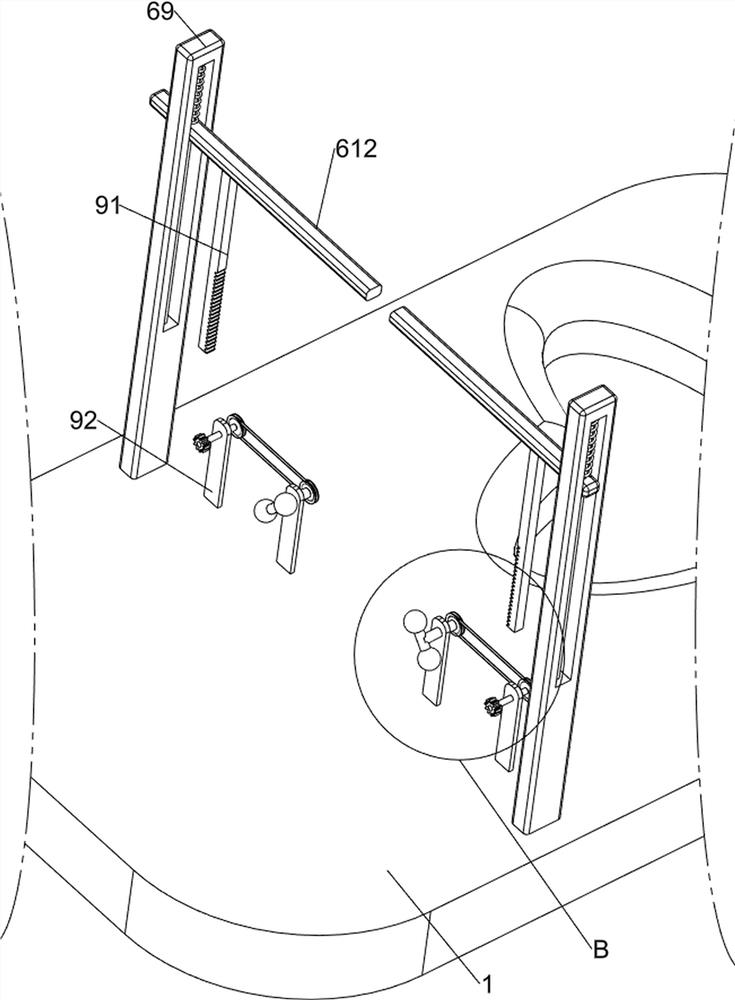

[0030] On the basis of Example 2, such as image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a vertical cutting mechanism 7 is also included, and the vertical cutting mechanism 7 is provided on the pressing block 68 and on the left side of the base 1. The vertical cutting mechanism 7 includes a first blade 71, a fourth connecting block 72, and a third wedge block 73. , the third slide rail 74, the third guide rod 75, the second spring 76, the third slide block 77, the second blade 78, the fifth connecting block 79, the fourth guide rod 710, the third spring 711 and the fourth wedge block 712, the first blade 71 is provided on the front and rear walls of the right side of the briquetting block 68, the fourth connecting block 72 is provided on the front and rear sides of the left wall of the briquetting block 68, and the third wedge-shaped block is provided at the bottom of the two fourth connecting blocks 72 73, the base 1 is provided with a third slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com