Auxiliary cutting treatment device for longitudinal cutting line

A processing device and slitting line technology, which is applied in woodworking safety devices, forming/shaping machines, springs/shock absorbers, etc., can solve the problems of large cutting errors of plank deviation and great danger to operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

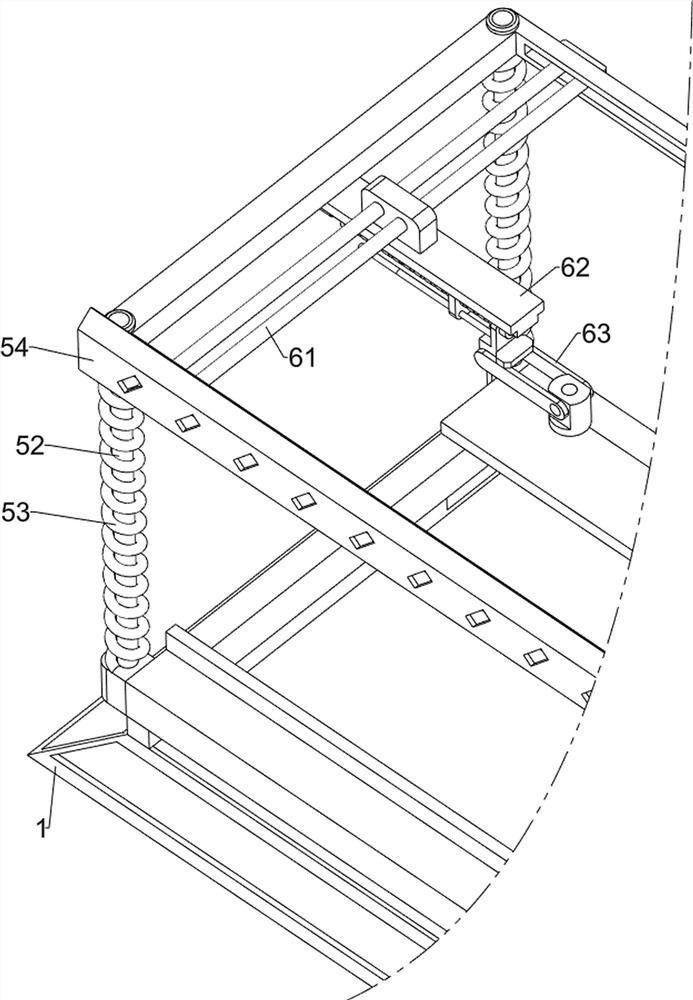

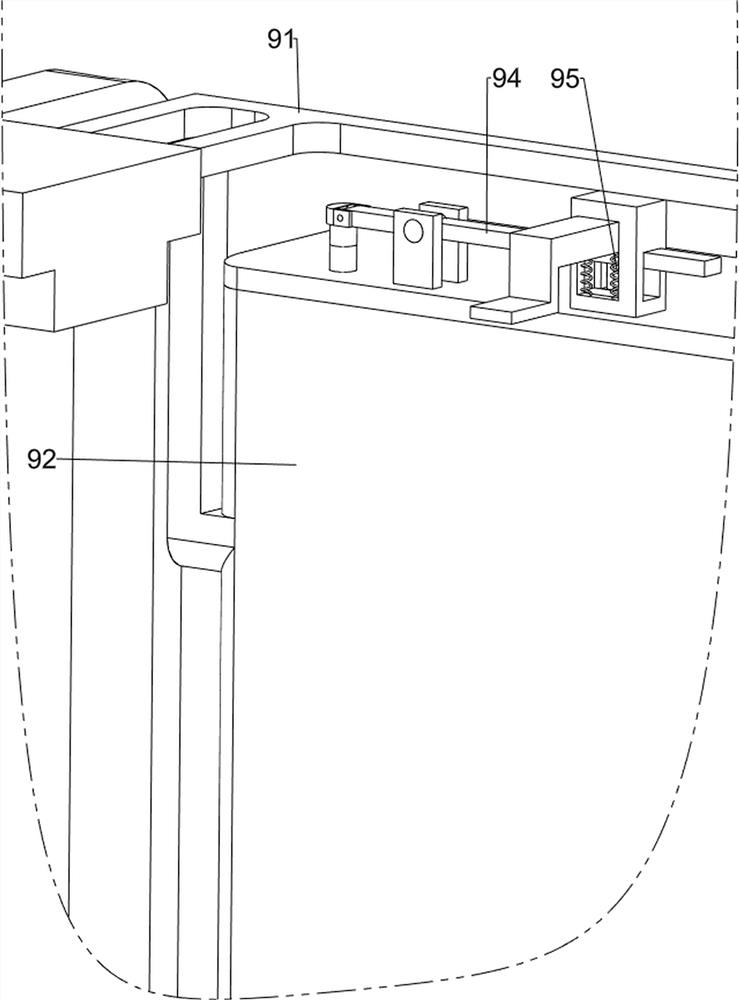

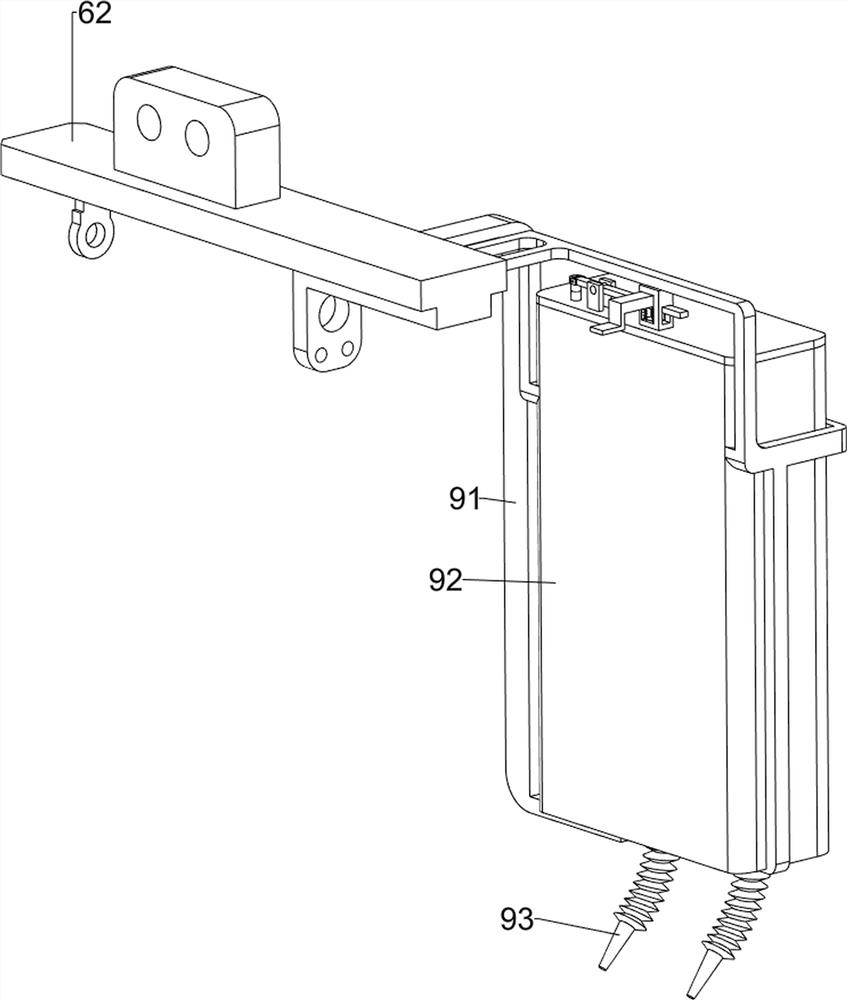

[0078] A slitting line auxiliary cutting processing device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 15 As shown, it includes a support frame 1, a motor 2, a cutting knife 3, a clamping mechanism 4, a lifting mechanism 5, a distance adjustment mechanism 6, a cutting angle adjustment mechanism 7 and a shock absorbing mechanism 10, and the support frame 1 is provided with a clamping mechanism 4. There is a lifting mechanism 5 on the top of the support frame 1, and the lifting mechanism 5 cooperates with the clamping mechanism 4. The lifting mechanism 5 is provided with a distance adjustment mechanism 6, and the distance adjustment mechanism 6 is provided with a cutting angle adjustment mechanism 7. 7 is provided with shock absorbing mechanism 10, and shock absorbing mechanism 10 cooperates with distance adjustment mechanism 6, and shock absorbing mechanism 10 is provided with ...

Embodiment 2

[0091] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, it also includes a pressing mechanism 8, and the pressing mechanism 8 includes a fixed frame 81, a moving frame 82, a fourth spring 83, a rack bar 84, a fifth spring 85 and a gear rod 86, and the second sliding frame 62 front The left side of the part is provided with a fixed frame 81, and the rear side sliding type in the fixed frame 81 is provided with a movable frame 82, and a fourth spring 83 is wound on the movable frame 82, and the two ends of the fourth spring 83 are connected with the fixed frame 81 and the movable frame 82 respectively. Connection, fixed frame 81 top sliding type is provided with rack bar 84, and the rear end of rack bar 84 contacts and cooperates with moving frame 82, is connected with the fifth spring 85 between the middle part of rack bar 84 and fixed frame 81, and the front of fixed frame 81 The side-rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com