Automatic material digging equipment for workshop processing

An automatic, workshop technology, used in metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problems of iron block damage, uneven manual operation force, easy to scratch hands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

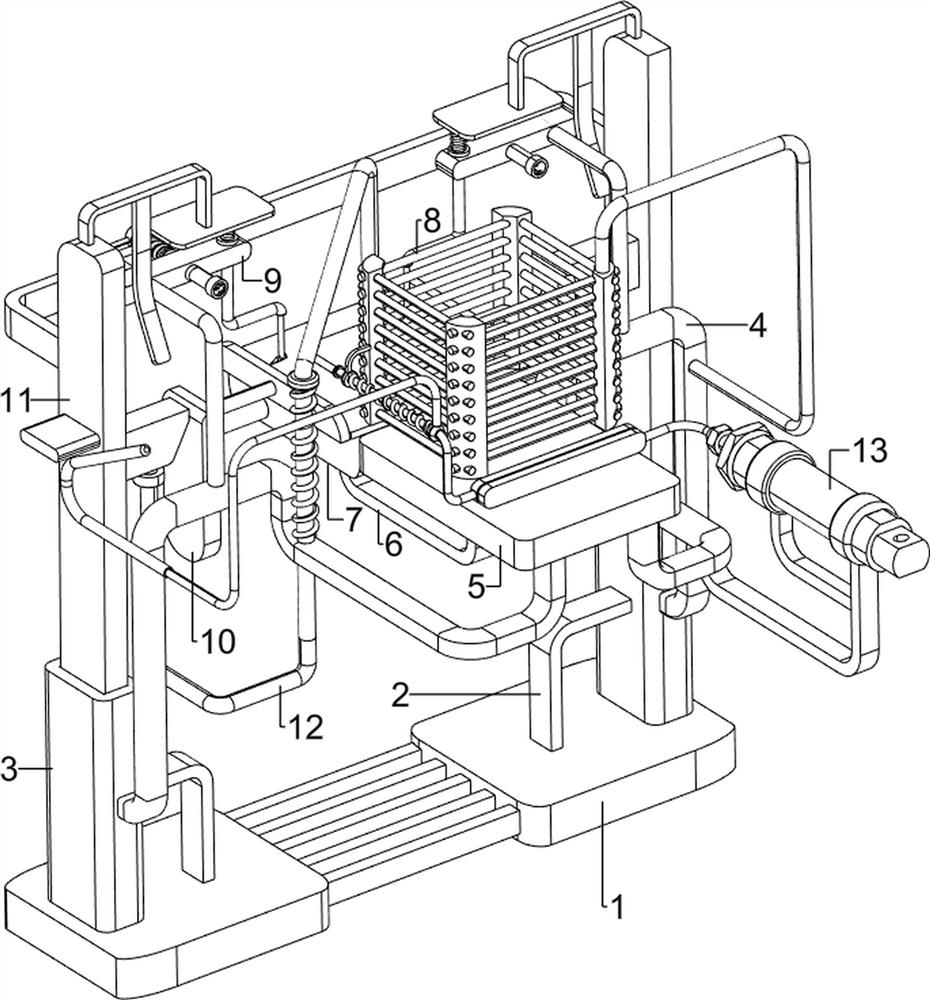

[0064] A kind of automatic digging equipment for workshop processing, such as figure 1As shown, it includes a first support plate 1, a first support frame 2, a telescopic sleeve 3, a fixed connecting frame 4, a second support plate 5, a second support frame 6, a third support plate 7, a pushing mechanism 8, and a Material mechanism 9, clamping mechanism 10 and auxiliary mechanism 11, first support plate 1 left and right sides are symmetrically provided with first support frame 2, first support plate 1 left and right sides are all provided with telescopic sleeve 3, telescopic sleeve 3 inner side and The outer side of the first support frame 2 is connected, and the middle of the front side of the telescopic sleeve 3 on both sides is symmetrically provided with a fixed connecting frame 4, and a second supporting plate 5 is arranged between the fixed connecting frames 4 on both sides, and the middle of the bottom of the second supporting plate 5 is left and right Both sides are pr...

Embodiment 2

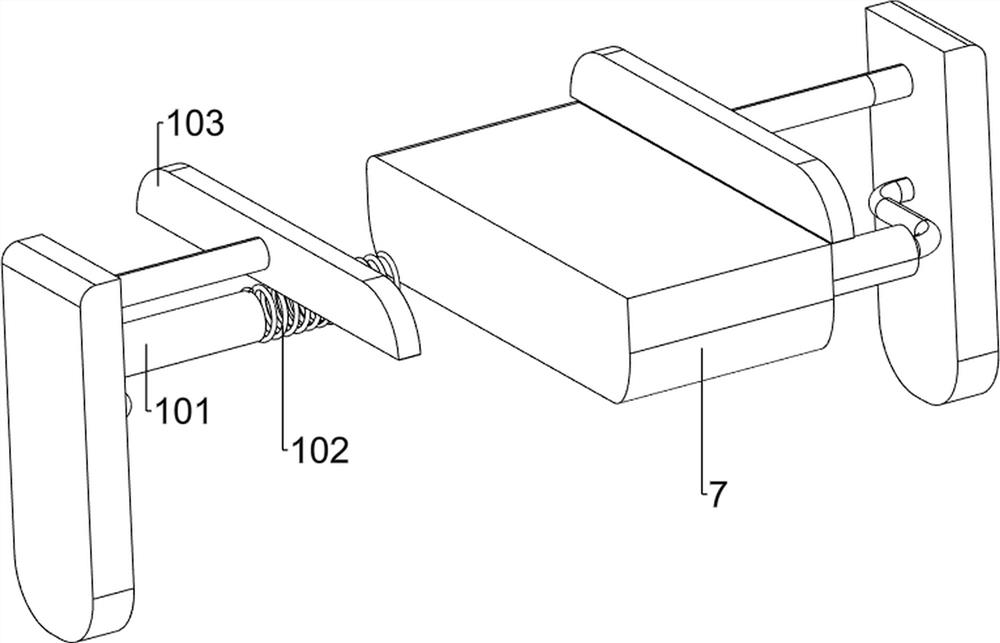

[0067] On the basis of Example 1, such as Figure 2-Figure 5 As shown, the pusher mechanism 8 includes a discharge frame 81, a third support frame 82, a pusher 83, a first spring 84 and a first cylindrical rod 85, and the upper side of the right side of the fixed engagement frame 4 right is provided with a release Material frame 81, the middle of discharging frame 81 left rear side is provided with the 3rd bracing frame 82, and the 3rd bracing frame 82 left side lower side sliding type is provided with pusher 83, and pusher 83 front left upper side is provided with first Cylindrical rod 85, the first spring 84 is wound around the rear side of the upper left part of the pusher 83, and the two ends of the first spring 84 are respectively connected with the first cylindrical rod 85 and the third support frame 82.

[0068] People put the iron block that needs to be pulled out into the feeding frame 81, and the iron block falls on the second support plate 5, and then people manuall...

Embodiment 3

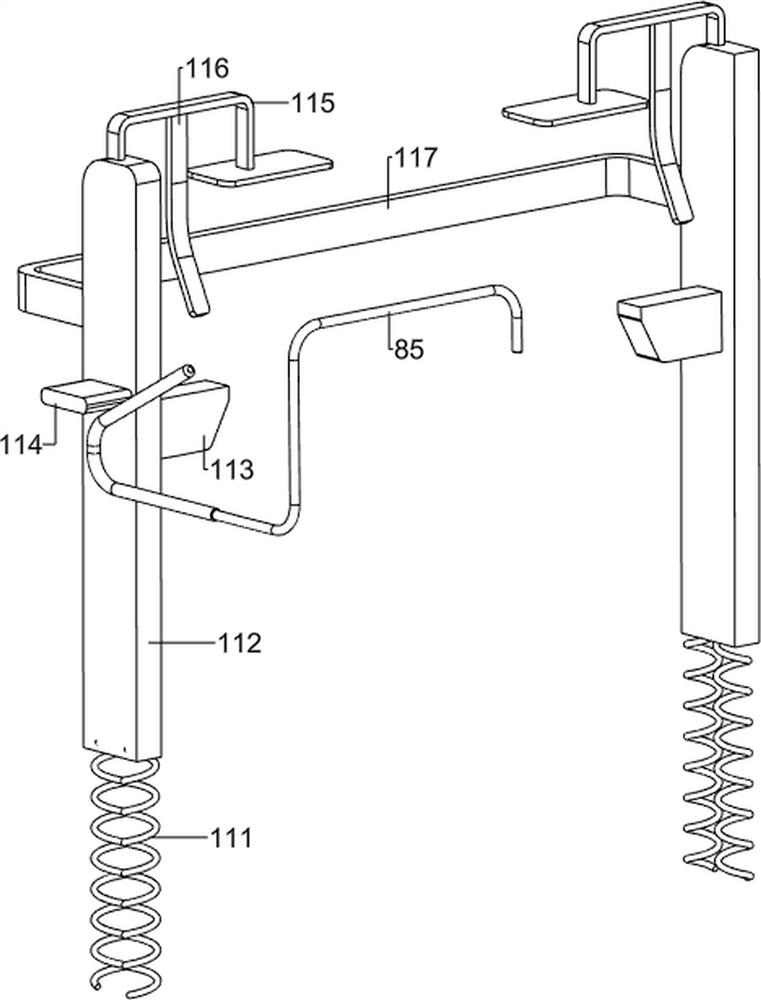

[0076] On the basis of Example 2, such as Image 6 , Figure 7 As shown, it also includes a pressing mechanism 12, and the pressing mechanism 12 includes a round piece bar 121, a pressure-assisting block 122 and a sixth spring 123, and the fixed connecting frame 4 top right rear side sliding type on the left side is provided with a round piece bar 121, the round bar 121 cooperates with the lower pressure block 113 on the left side, the top of the right side of the round bar 121 is provided with an auxiliary pressing block 122, and the upper side of the right side of the round bar 121 is wound with a sixth spring 123, and the sixth spring 123 has two The ends are respectively connected with the round bar 121 and the fixed adapter frame 4.

[0077] When the lower pressing block 113 moves downward, the lower pressing block 113 drives the round bar 121 to move downward, and the sixth spring 123 is compressed, thereby driving the auxiliary pressing block 122 to move downward, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com