Efficient positioning welding equipment for alloy steel for high-end equipment manufacturing

A technology for positioning welding and alloy steel, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of eye hazard and difficult quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

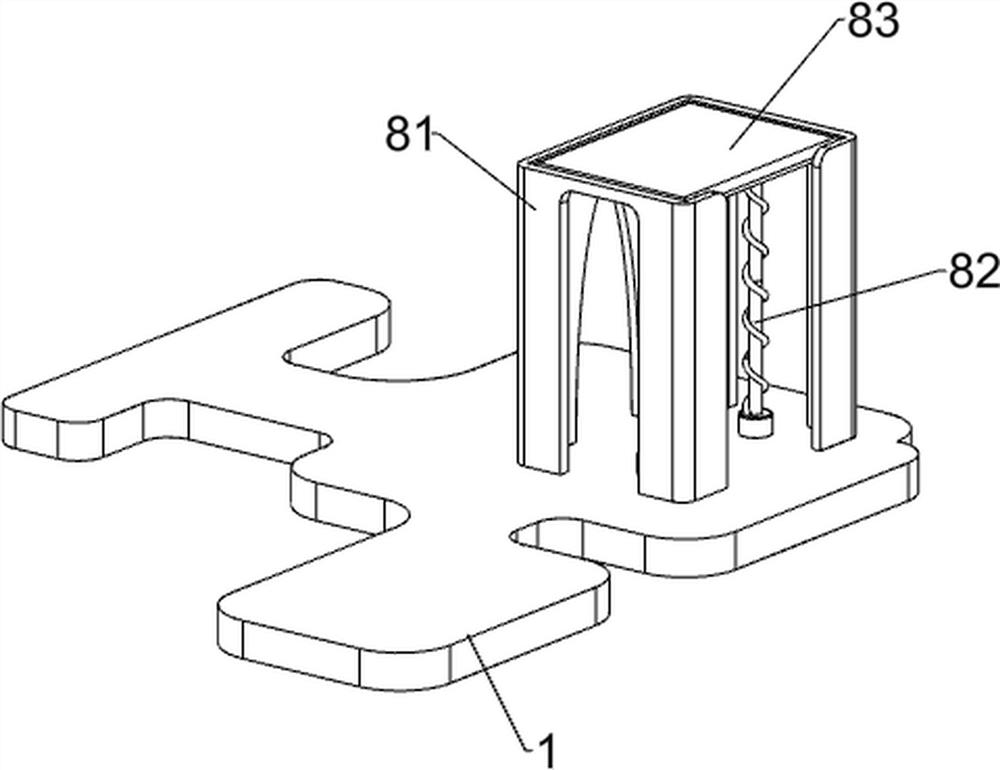

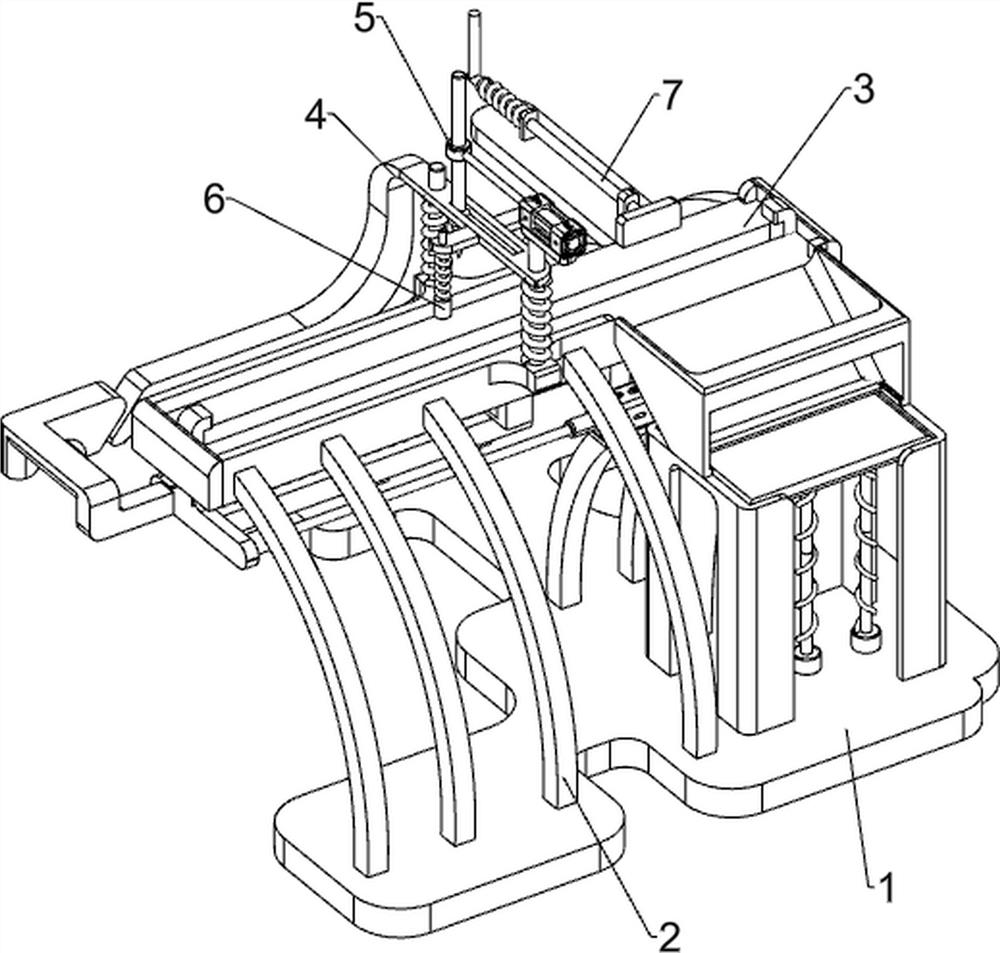

[0029] A high-end equipment manufacturing high-efficiency positioning welding equipment for alloy steel, such as figure 1 As shown, it includes a base plate 1, a bracket 2, a positioning mechanism 3, a pressing mechanism 4 and a welding mechanism 5. The base plate 1 is provided with a bracket 2, a positioning mechanism 3 is provided between the brackets 2, and a pressing mechanism 3 is provided in the middle of the positioning mechanism 3. Mechanism 4, a welding mechanism 5 is provided on the top of the left front side of the pressing mechanism 4 .

[0030] When people need to weld alloy steel, they can use this high-end equipment to manufacture high-efficiency positioning welding equipment for alloy steel. First, people need to put the alloy steel on the positioning mechanism 3, and then start the positioning mechanism 3, and the positioning mechanism 3 will drive The pressing mechanism 4 moves downwards, and then starts the welding mechanism 5. The welding mechanism 5 welds ...

Embodiment 2

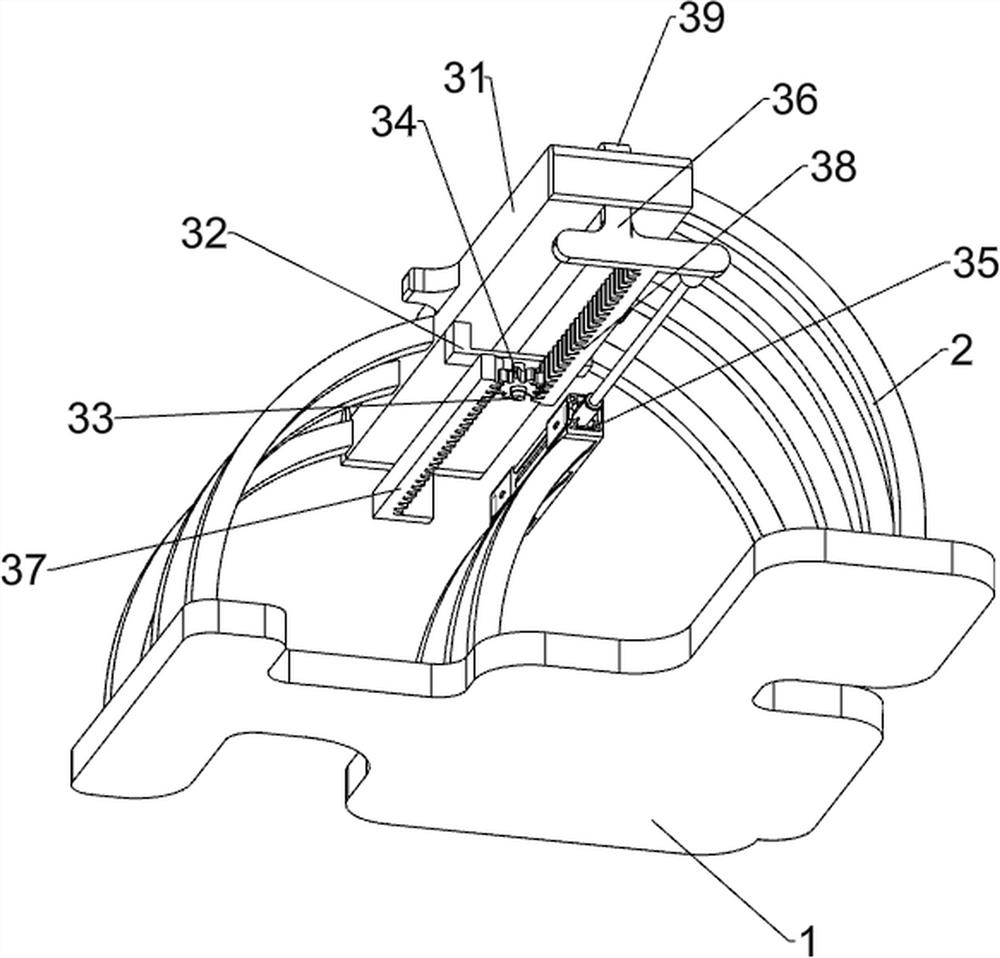

[0032] On the basis of Example 1, such as Figure 2-Figure 7 As shown, the positioning mechanism 3 includes a material holding plate 31, a mounting block 32, a rotating shaft 33, a spur gear 34, a first cylinder 35, a push plate 36, a first rack 37, a second rack 38 and a magnet 39. There is a material holding plate 31 between the side brackets 2, a mounting block 32 is provided at the middle bottom of the material holding plate 31, and a rotating shaft 33 is arranged at the middle bottom of the mounting block 32, and a spur gear 34 is provided on the rotating shaft 33. The middle support 2 The top is equipped with a first cylinder 35, the middle sliding type on the left side of the material holding plate 31 is provided with a push plate 36, the pushing plate 36 is connected with the telescopic rod of the first cylinder 35, and the middle sliding type on the right side of the material holding plate 31 is provided with a first tooth Bar 37, the upper right side of the first rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com