Partition plate high-precision grooving equipment for building decoration

A kind of grooving equipment and high-precision technology, which is used in forming/shaping machines, wood processing appliances, manufacturing tools, etc., can solve the problems of prone to grooving deviation, inability to quickly clean wood dust and other problems, and achieve the effect of avoiding sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

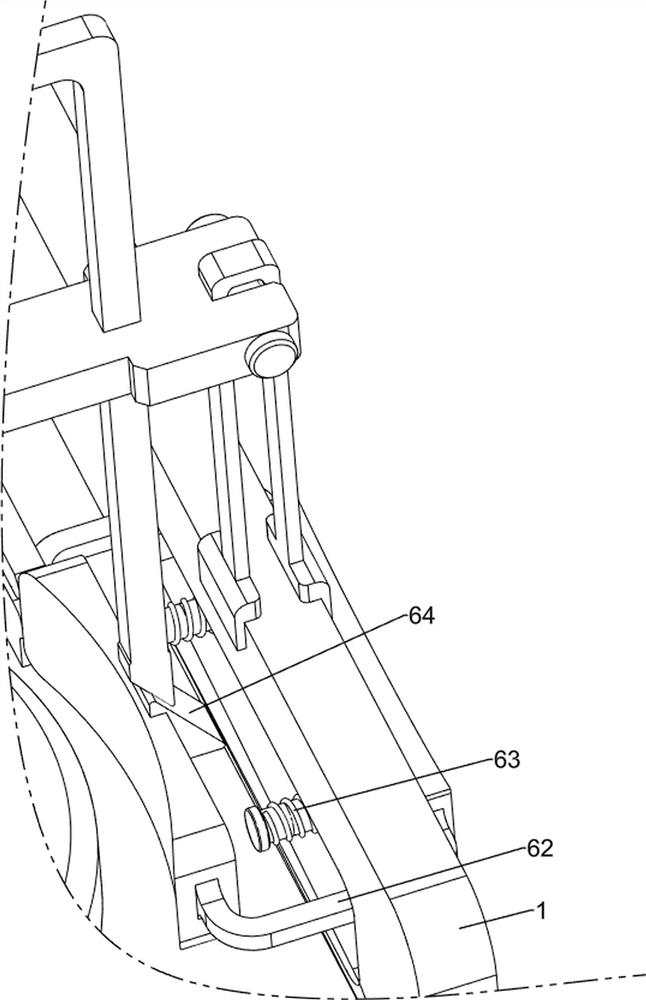

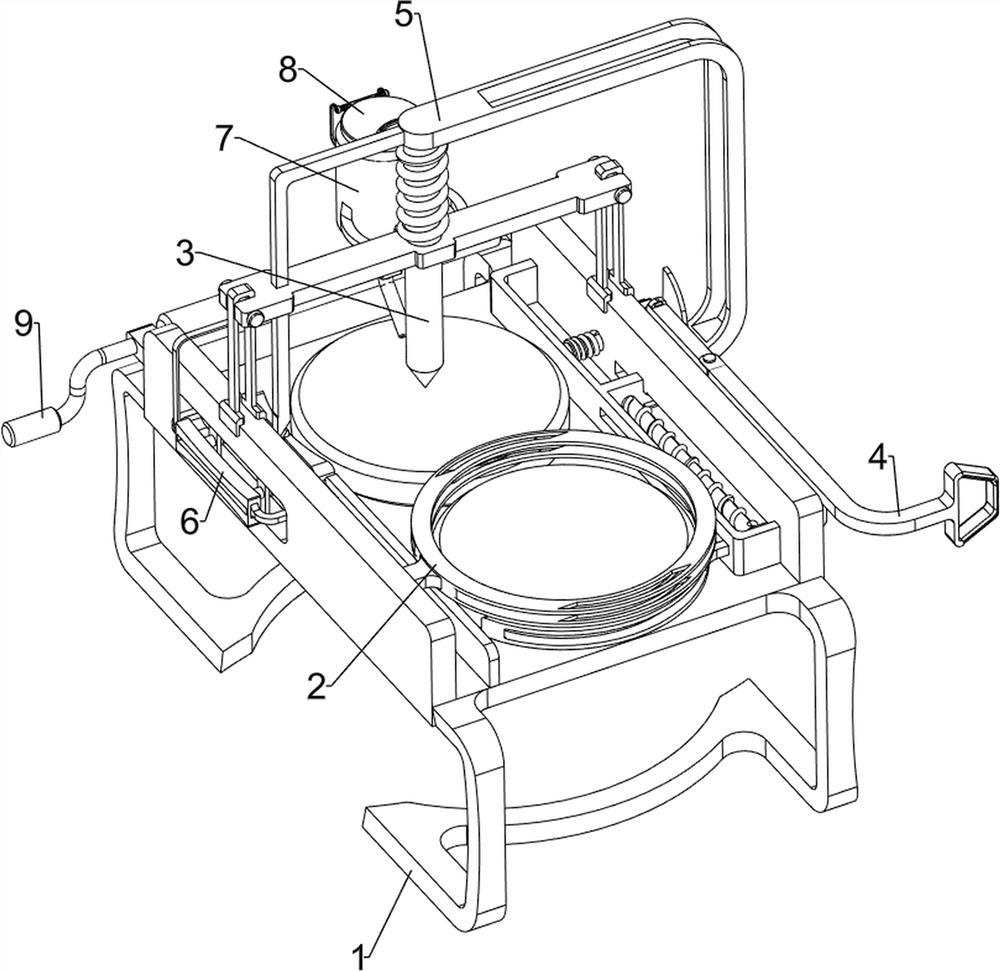

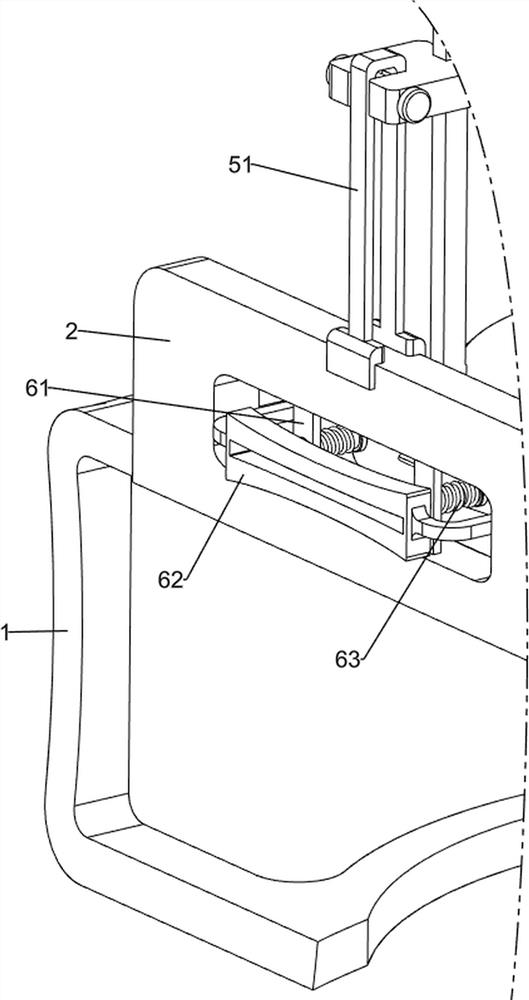

[0070] A high-precision slotting equipment for partitions used in building decoration, such as Figure 1-12 As shown, it includes a first support base 1, a positioning frame 2, a slotter 3, a pushing mechanism 4, a pressing mechanism 5, a clamping mechanism 6 and a cooling mechanism 7, and the upper side of the left part of the first support base 1 is provided with Positioning frame 2, first support base 1 upper middle right side is provided with down-pressing mechanism 5, and down-pressing mechanism 5 is provided with slotter 3, and first support base 1 left side inner upper side is provided with pusher mechanism 4, the first A clamping mechanism 6 is arranged on the inner right rear side of the upper part of the supporting base 1 , and a cooling mechanism 7 is arranged on the pressing mechanism 5 , and the cooling mechanism 7 cooperates with the clamping mechanism 6 .

[0071] In the construction of building decoration, when people need to slot the partition, this high-preci...

Embodiment 2

[0081] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 13-16 As shown, the opening and closing mechanism 8 is also included. The opening and closing mechanism 8 includes a first fixed mount 81, an opening and closing plate 82 and a torsion spring 83. Rotation between a fixed frame 81 upper side is provided with opening and closing plate 82, and opening and closing plate 82 contacts and cooperates with water storage tank 71, and opening and closing plate 82 right side front and back two parts are all wound with torsion spring 83, and torsion spring 83 two ends are connected with same side respectively. The first fixed frame 81 is connected with the opening and closing plate 82.

[0082] People first manually flip the opening and closing plate 82 to the right. At this time, the torsion spring 83 is twisted and deformed, so that the opening and closing plate 82 is opened, and clean water can be poured into the water storage tank 71, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com