Medical square tablet mashing equipment for pediatric department

A square and tablet technology, applied in the directions of feeding and oral medicine, grain processing, etc., can solve the problems of labor-intensive, inability to mash the tablets, etc., and achieve the effect of convenient operation and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

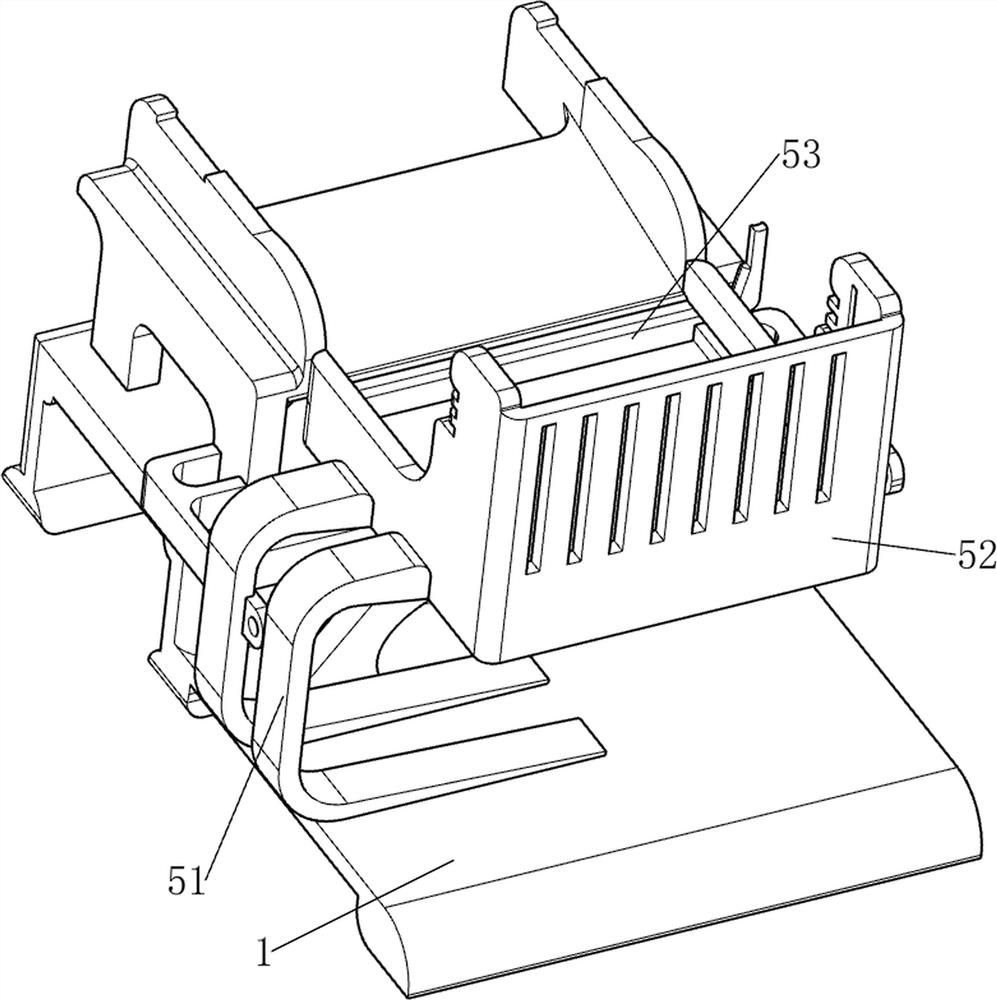

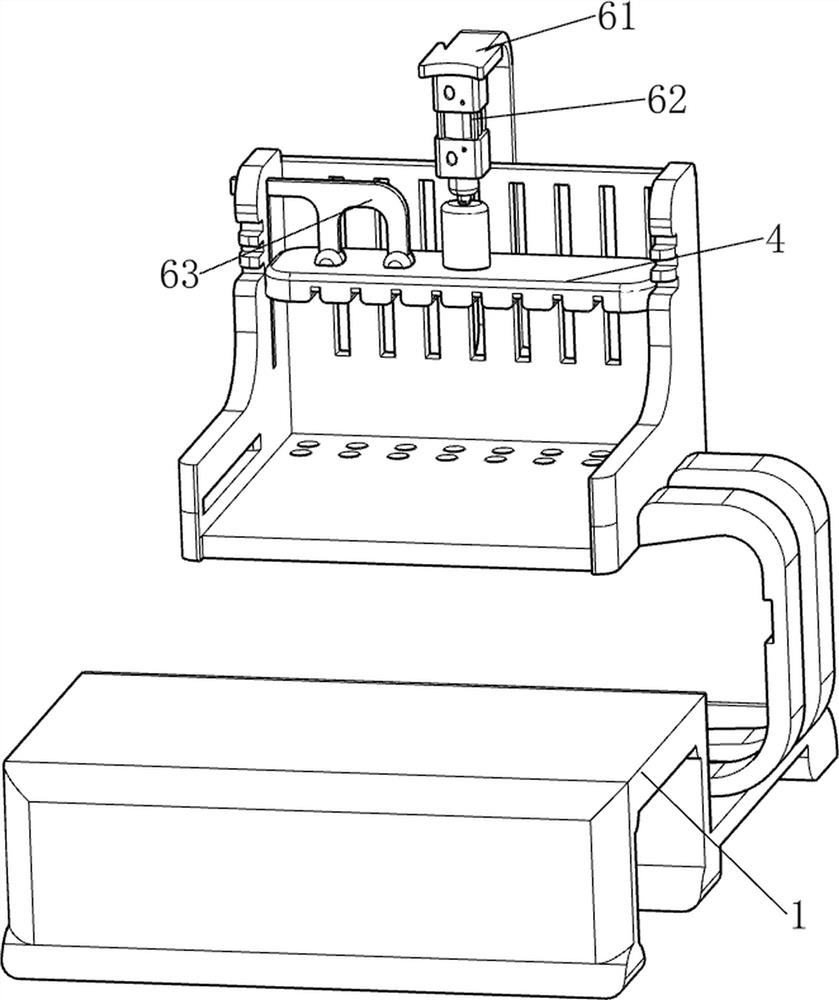

[0062] A medical pediatric crushing equipment for square pills, such as figure 1 As shown, it includes an underframe 1, a first supporting block 2, a second supporting block 3, an extruding block 4, a pushing mechanism 5 and an extruding mechanism 6, and the upper front side of the underframe 1 is provided with a first supporting block 2, A second support block 3 is provided between the upper rear side of the first support block 2 and the upper rear side of the underframe 1, and a pushing mechanism 5 is arranged between the underframe 1, the first support block 2 and the second support block 3. An extruding mechanism 6 is arranged on the material mechanism 5 , and an extruding block 4 is slidably arranged on the pushing mechanism 5 , and the extruding block 4 is fixedly connected with the extruding mechanism 6 .

[0063] When people need to smash square tablets, they can use this kind of equipment for crushing square tablets for medical use in pediatrics. First, people need to...

Embodiment 2

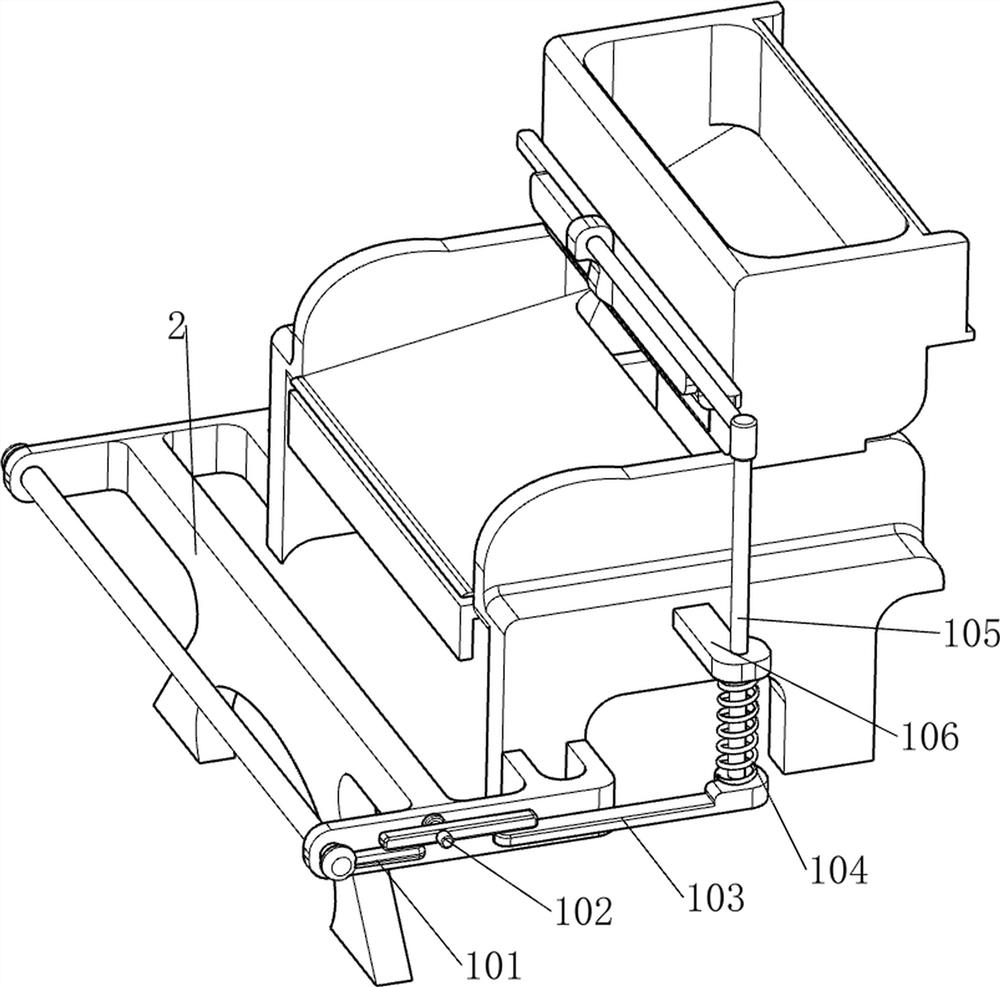

[0065] On the basis of Example 1, such as figure 2 with image 3 As shown, the pusher mechanism 5 includes a first support frame 51, a pusher frame 52 and a pusher block 53. Two first support frames 51 are arranged on the left front side of the bottom frame 1, and the first support frame 51 on the rear side is upper left. The side is connected with the first support block 2, and a pusher frame 52 is arranged between the right sides of the upper parts of the two first support frames 51, and the rear side of the pusher frame 52 is slidingly provided with a pusher block 53, and the pusher block 53 is connected to the second The support block 3 is slidably connected.

[0066]After the tablet rolls onto the pusher frame 52, people need to push the pusher block 53 to slide forward, and the pusher block 53 can push the tablet to the bottom of the extrusion block 4 to realize the effect of pushing the material. Pull the pushing block 53 and slide back to reset.

[0067] The extrud...

Embodiment 3

[0070] On the basis of Example 2, such as Figure 4-Figure 7 As shown, a blanking mechanism 7 is also included, and the blanking mechanism 7 includes a blanking frame 71, a first sliding sleeve 72, a first spring 73 and a stopper 74, and the rear side of the second support block 3 is provided with a blanking frame 71, the left and right sides of the front part of the blanking frame 71 are provided with the first sliding sleeve 72, and the sliding type between the two first sliding sleeves 72 is provided with a stopper 74, and the top of the left and right sides of the stopper 74 is connected with the first sliding sleeve on the same side. First springs 73 are connected between the sliding sleeves 72 .

[0071] People can pour a large amount of tablets into the blanking frame 71, so that the tablets fall onto the second support block 3, and thus fall onto the pusher frame 52 to realize the effect of blanking. When blanking is not required, people can It is necessary to manuall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com