Arch-shaped toothed nail forming device for rice and wheat thresher roller

A forming device and thresher technology, which is applied in the field of bow-shaped nail forming device for rice and wheat thresher drum, can solve the problems of low work efficiency, low processing precision, bending of multiple tooth nails, etc., and achieve the collection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

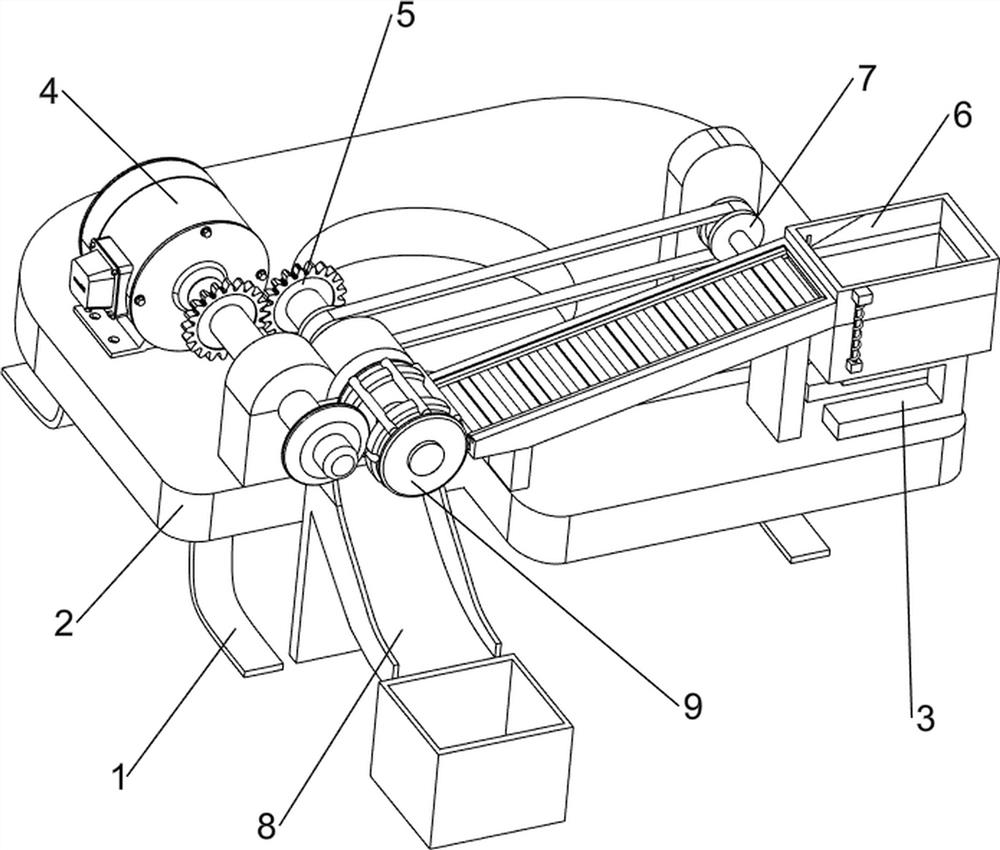

[0026] A bow-shaped tooth nail forming device for a rice and wheat thresher drum, such as Figure 1-Figure 3 As shown, it includes a tripod 1, a workbench 2, a mounting frame 3, a bending mechanism 4 and a feeding mechanism 5, four tripods 1 are evenly arranged at the bottom of the workbench 2, and two mounting brackets are arranged on the top of the right side of the workbench 2. Frame 3, the top of the left side of the workbench 2 is provided with a bending mechanism 4, and the top of the left side of the workbench 2 is provided with a feeding mechanism 5.

[0027] When people want to bend the tooth nails into a bow shape, they can use this bow-shaped tooth nail forming device for the rice and wheat threshing machine drum. First, the user places the tooth nails on the feeding mechanism 5, and the teeth The nails are sent to the bending mechanism 4, and the bending mechanism 4 bends the tooth nails into a bow shape, thereby realizing the bending effect.

[0028] The bending ...

Embodiment 2

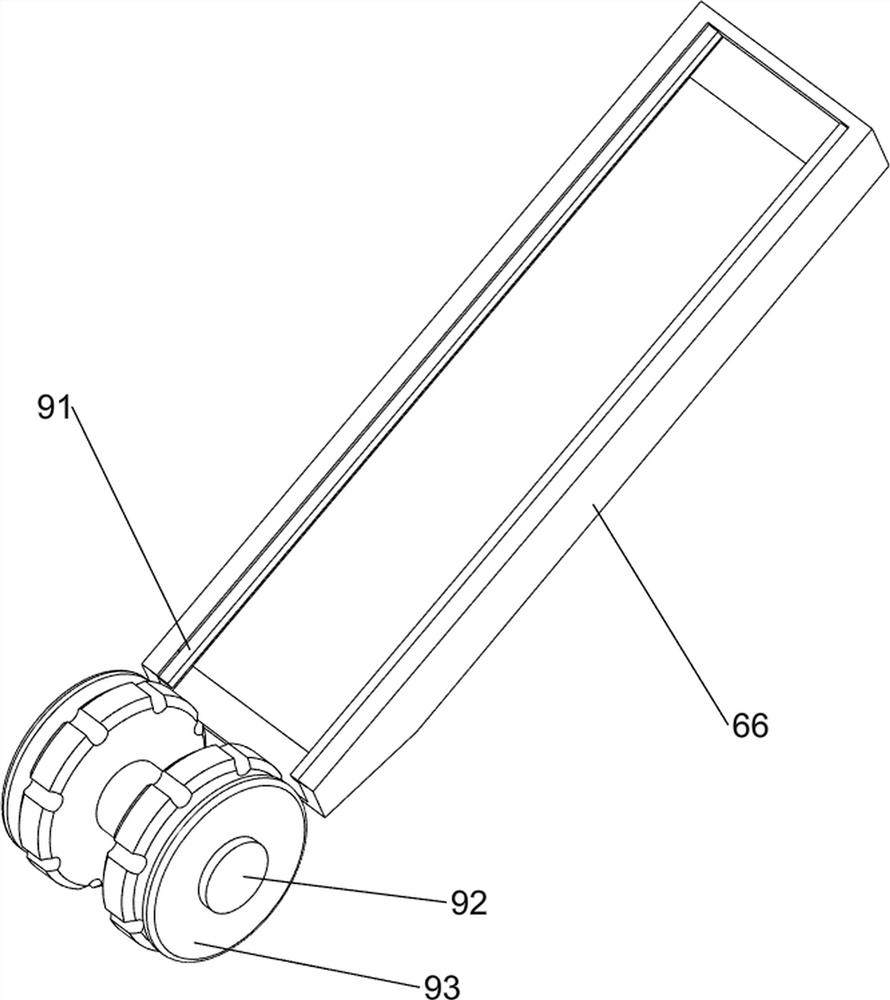

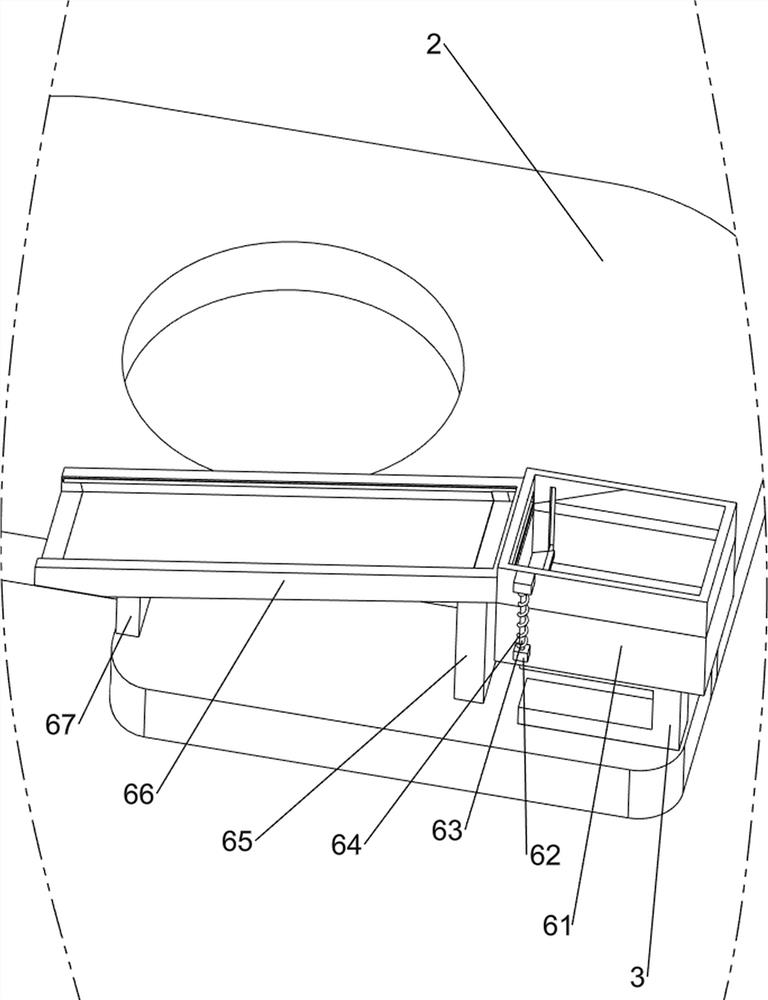

[0033] On the basis of Example 1, such as Figure 4-Figure 7 As shown, it also includes a blanking mechanism 6. The top of the right side of the workbench 2 is provided with a blanking mechanism 6. The blanking mechanism 6 includes a blanking box 61, a movable push plate 62, a slide bar 63, a spring 64, and a rear support block. 65, the blanking chute 66 and the front support block 67, the top of the two installation frames 3 is provided with a blanking box 61, the lower part of the blanking box 61 inner wall is slidingly provided with a movable push plate 62, and the top of the front side of the movable push plate 62 is provided with Slide bar 63, spring 64 is wound on the slide bar 63, and the top of spring 64 is connected with slide bar 63, and the bottom end of spring 64 is connected with movable push plate 62. A front support block 67 is provided on the side top, and a blanking chute 66 is provided between the rear support block 65 and the top of the front support block 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com