Frame plate bending device for new energy automobile

A new energy vehicle, bending device technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of manpower consumption, and achieve the effect of reducing manpower consumption, easy operation of manpower, and manpower saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

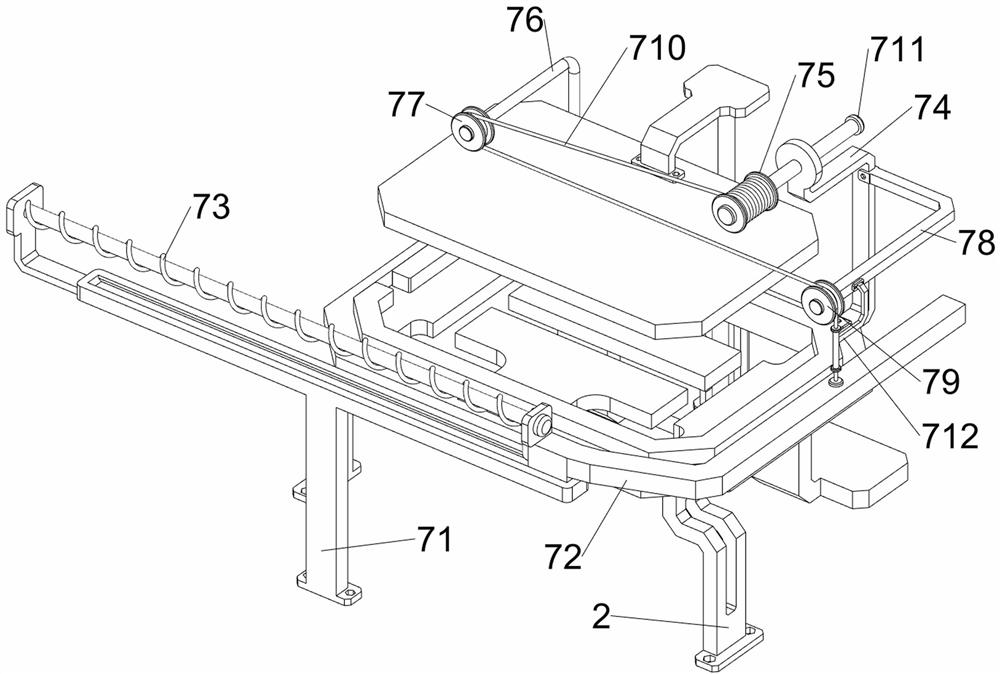

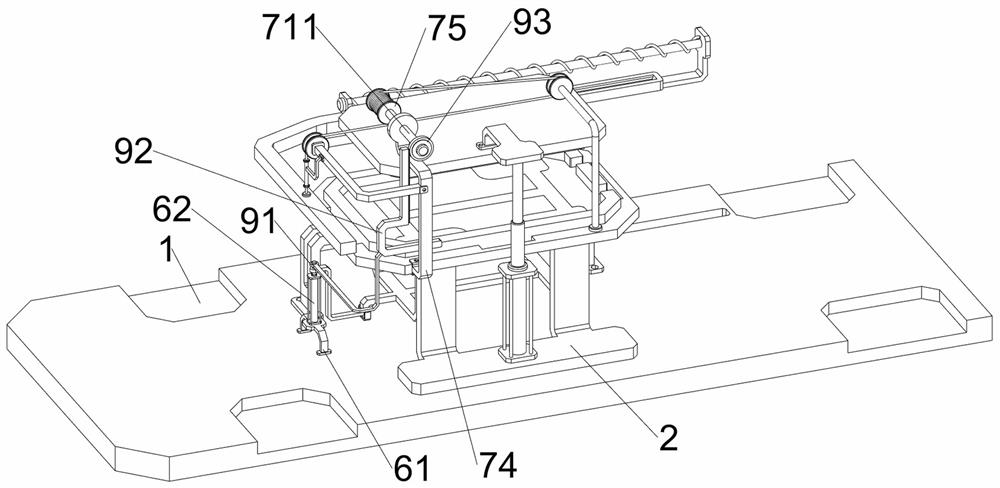

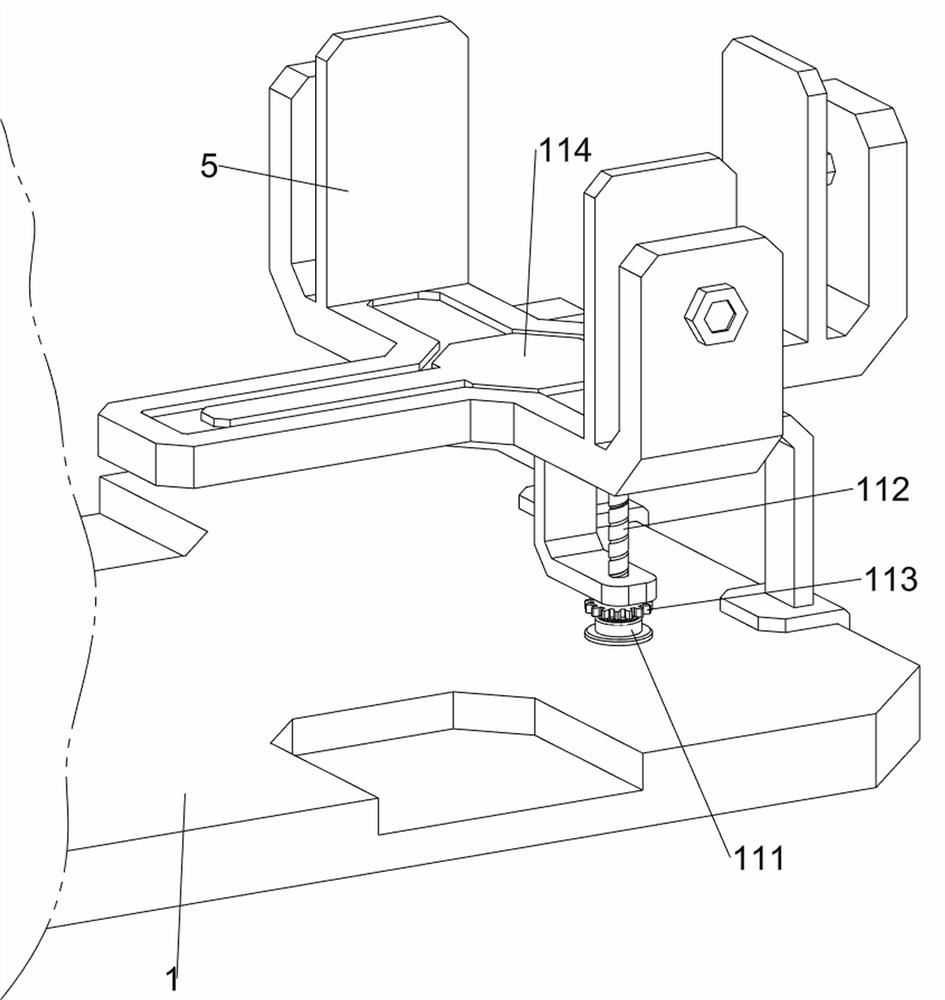

[0041] A bending device for new energy vehicle frame plates, such as Figure 1-5 As shown, it includes a base plate 1, a material setting table 2, a first cylinder 3, a bending plate 4, a storage rack 5, a material ejecting mechanism 6 and a material pushing mechanism 7, and a material setting table 2 is connected in the middle of the top of the bottom plate 1. Platform 2 is used to place frame plates, and a first air cylinder 3 is installed on the rear side of the material placing table 2, and a bending plate 4 is connected to the telescopic rod of the first air cylinder 3, which is used to bend the frame plates. The curved plate 4 is located above the material setting table 2, and the top right side of the bottom plate 1 is connected with a storage rack 5, the storage rack 5 is used to store the frame plate, and a lifting mechanism 6 is provided between the bottom plate 1 and the material setting table 2, and the material lifting mechanism 6 It is used to push out the bent f...

Embodiment 2

[0046] On the basis of Example 1, such as figure 1 , Figure 6 , Figure 7 and Figure 8 As shown, a positioning mechanism 8 is also included. The positioning mechanism 8 is used to position the frame plate. The positioning mechanism 8 includes a positioning plate 81, a first rack 82, a first gear 83, a second rack 84 and a third branch. Rod 85 is slidingly connected with a positioning plate 81 on the material setting table 2, and the positioning plate 81 is used to position the frame plate. The position of the bar 82 is connected with a third pole 85, and the third pole 85 is connected with a first gear 83 in a rotational manner, and the rear side of the bottom of the bending plate 4 is connected with a second rack 84, and the first rack 82 is connected with the first gear The left side of the gear 83 meshes, and the second rack 84 descends to mesh with the left side of the first gear 83 .

[0047] The bending plate 4 drives the second tooth bar 84 to move downward when m...

Embodiment 3

[0051] On the basis of Example 2, such as figure 1 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, a collection mechanism 10 is also included, and the collection mechanism 10 is used to collect the bent frame plates. The collection mechanism 10 includes a third support plate 101, a collection frame 102, a second guide rail 103, a third rack 104, The second spring 105, the first bearing seat 106, the second gear 107, the first threaded rod 108, the connecting plate 109 and the push rod 1010; There is a first bearing seat 106, the first bearing seat 106 is rotationally connected with a first threaded rod 108, the bottom of the first threaded rod 108 is connected with a second gear 107, and the first threaded rod 108 is threadedly connected with a connecting plate 109, The front side of connecting plate 109 is connected with collecting frame 102, and collecting frame 102 is used for collecting the frame plate after bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com