Agricultural organic fertilizer dehydration equipment

A technology for dehydration equipment and organic fertilizers. It is applied in lighting and heating equipment, drying solid materials, and drying solid materials without heating. It can solve the problems of manual cutting, inability to perform extrusion dehydration, and inability to discharge materials multiple times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

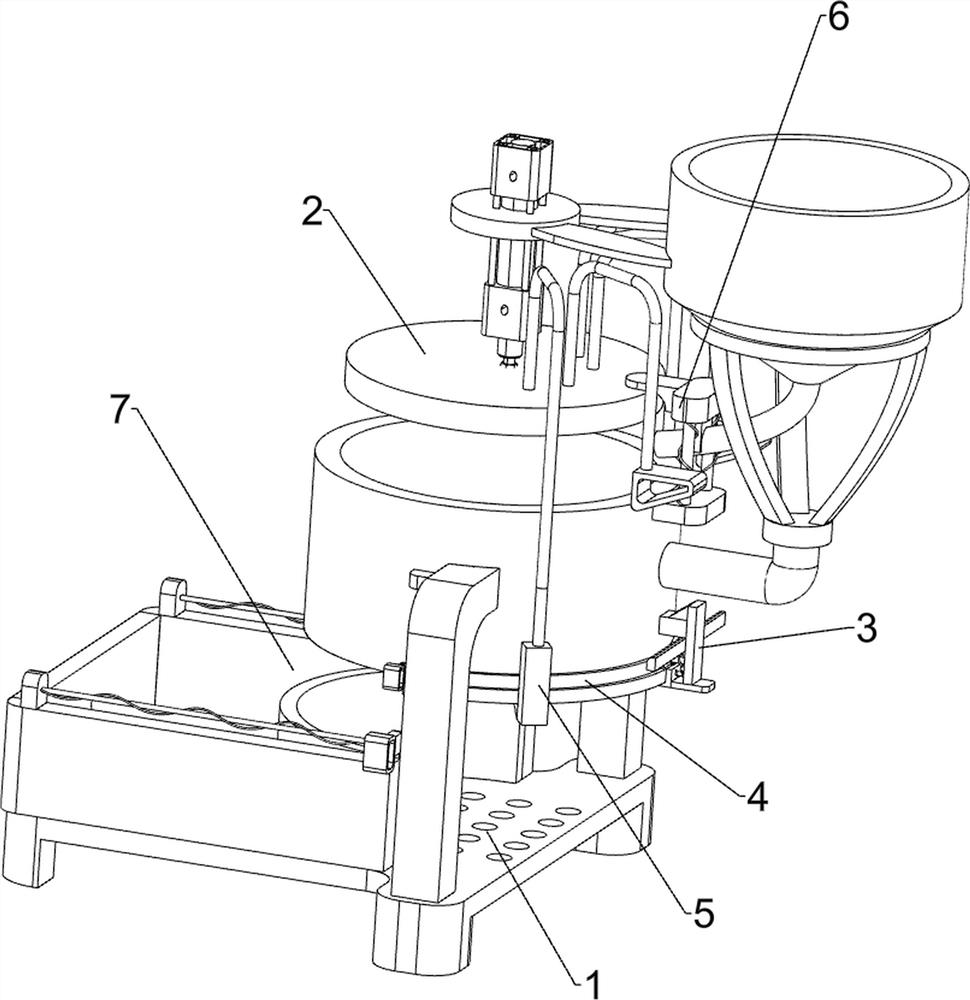

[0065] A kind of agricultural organic fertilizer dehydration equipment, such as figure 1 As shown, it includes a frame 1, an extrusion dehydration mechanism 2 and a discharge mechanism 3. The extrusion dehydration mechanism 2 is provided on the upper rear side of the frame 1, and the discharge mechanism 3 is provided on the upper rear side of the frame 1.

[0066] When people want to dehydrate organic fertilizers, they can use this agricultural organic fertilizer dehydration equipment. First, the user pours the organic fertilizers on the frame 1, starts the extrusion dehydration mechanism 2, and the extrusion dehydration mechanism 2 is used to dehydrate the organic fertilizers. Extrusion dehydration is carried out, and after the extrusion dehydration is completed, the organic fertilizer is pushed out through the discharge mechanism 3, and the extrusion dehydration mechanism 2 is closed.

Embodiment 2

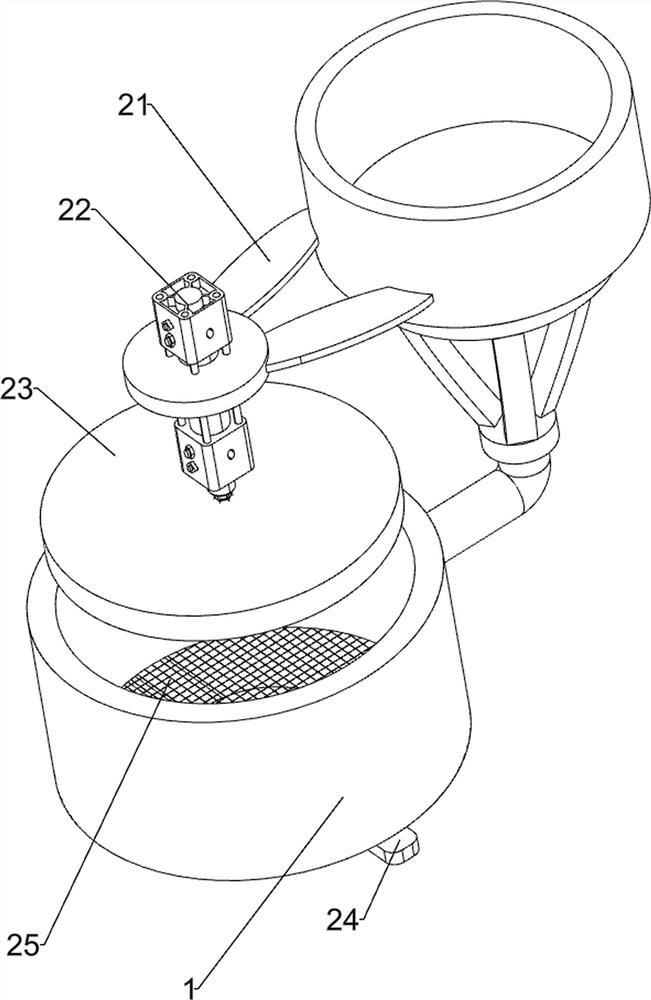

[0068] On the basis of Example 1, such as figure 2 and image 3Shown, extrusion dehydration mechanism 2 comprises first support plate 21, cylinder 22, pressing plate 23, second support plate 24 and filter screen 25, and frame 1 upper rear side top is provided with first support plate 21, the first support Plate 21 middle part is equipped with cylinder 22, and cylinder 22 telescoping rods are connected with pressing plate 23, and frame 1 is provided with second support plate 24 by discharging mechanism 3 sliding type, and filter screen 25 is installed on the second support plate 24.

[0069] The user starts the cylinder 22, and the telescopic rod of the cylinder 22 extends downward, thereby driving the pressure plate 23 to move downward, and squeezes and dehydrates the organic fertilizer. After completion, the user controls the telescopic rod of the cylinder 22 to shorten upwards, thereby driving the pressing plate 23 to move upwards, so that the pressing plate 23 is away fro...

Embodiment 3

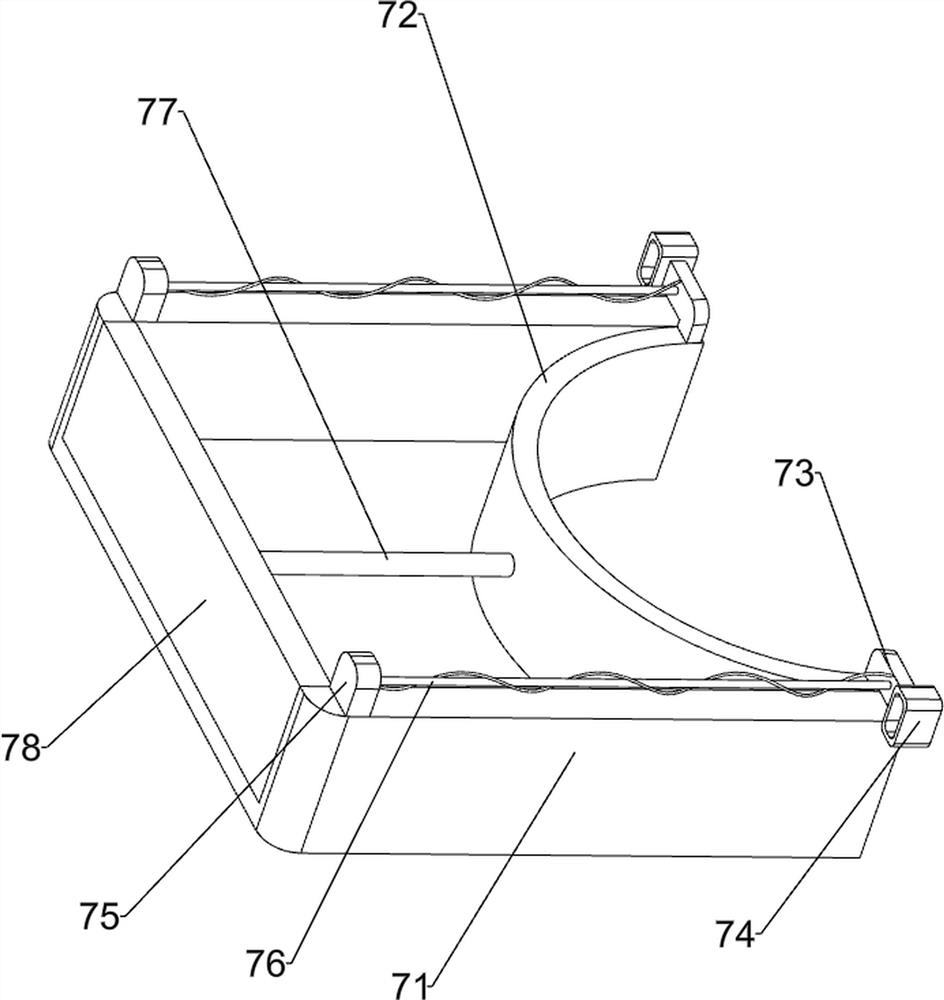

[0073] On the basis of Example 2, such as Figure 4-Figure 7 As shown, a scraper mechanism 4 is also included. The scraper mechanism 4 is arranged on the top of the arc-shaped connecting plate 35. The scraper mechanism 4 includes a first arc-shaped scraper 41, a first handle 42, a third telescopic assembly 43 and a first Three fixed blocks 44, the first arc scraper 41 is provided on the top of the arc connecting plate 35, the first handle 42 is provided on the left and right sides of the first arc scraper 41, and the first arc scraper 41 rear side middle part is provided with There is a third fixed block 44 , and a third telescopic assembly 43 is connected between the third fixed block 44 and the first connecting block 38 .

[0074] When the organic fertilizer is dehydrated, push the first handle 42 forward, thereby driving the first arc-shaped scraper 41 to move forward, and then drive the third fixed block 44 to move forward, and the third telescopic assembly 43 is extended,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com