Aluminum scrap loader

A technology for aluminum shavings and shavings, applied in the field of car loader, can solve the problems of wasting space, laboring, easy arm soreness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A car loader for aluminum shavings, such as figure 1 As shown, it includes a first support frame 1, a second fixed connecting rod 2, a chip rack 3, a thinning mechanism 4 and an accelerated discharge mechanism 5, and a second fixed connecting rod 2 is provided on the front side of the first supporting frame 1 , A chip rack 3 is connected between the top of the first support frame 1 and the second fixed connecting rod 2, the chip rack 3 is provided with a thinning mechanism 4, and the top of the chip rack 3 is provided with an accelerated discharge mechanism 5.

[0063] When people need to load aluminum scraps into cars, they can use this loader. First, put the aluminum scraps from the chip rack 3, and the aluminum scraps will slide down obliquely and pass through the finer mechanism 4 for crushing and thinning, and then pass through Accelerate the discharge mechanism 5 to push the aluminum chips forward, accelerate the rapid discharge of the aluminum chips to the car, r...

Embodiment 2

[0065] On the basis of Example 1, such as figure 2 and image 3 As shown, the thinning mechanism 4 includes a long gear set 41, a rotating shaft 42, a breaker 43 and a fixed ring sleeve 44, and the upper and lower parts of the chip loading rack 3 are internally rotated to be provided with a rotating shaft 42, and the two rotating shafts 42 left A long gear set 41 is provided between the sides, a breaker 43 is provided on the rotating shaft 42, and a fixed ring sleeve 44 is provided at the right end of the rotating shaft 42 .

[0066] When the aluminum chips pass through the pulverizer 43, the long gear set 41 is manually rotated, and the long gear set 41 drives the upper and lower pulverizers 43 to rotate continuously through the rotating shaft 42, and the pulverizer 43 grinds and refines the aluminum chips to reduce aluminum Crumbs occupy more space due to their irregular volume.

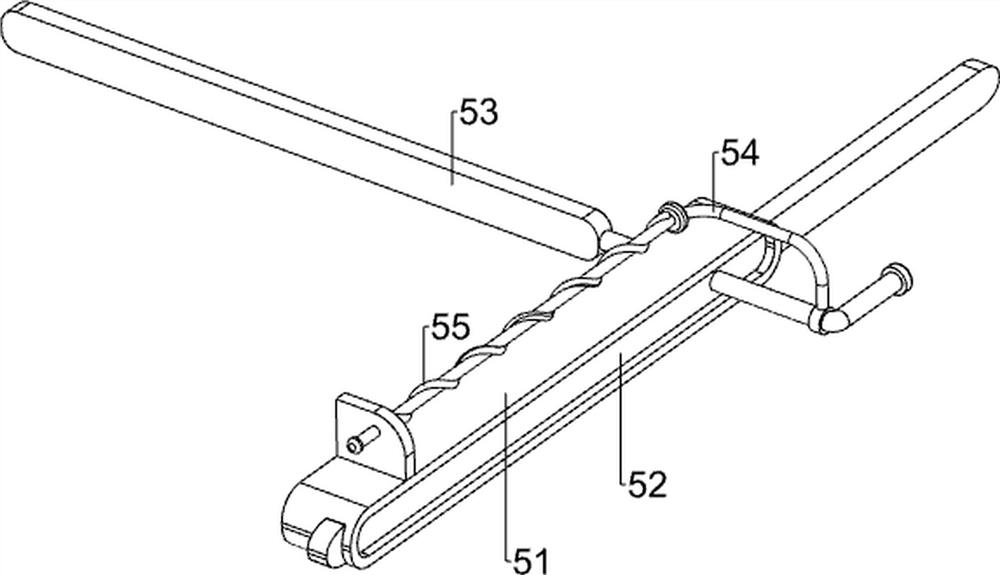

[0067]Accelerate the discharge mechanism 5 and include the first stabilizer 51, the sliding ...

Embodiment 3

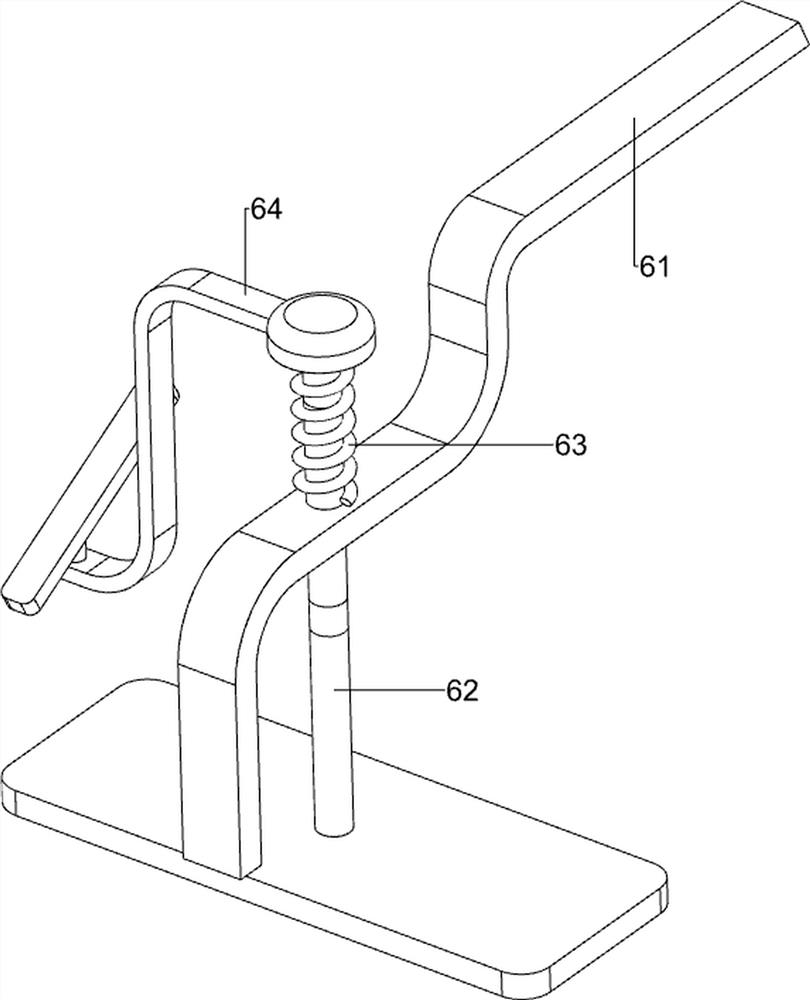

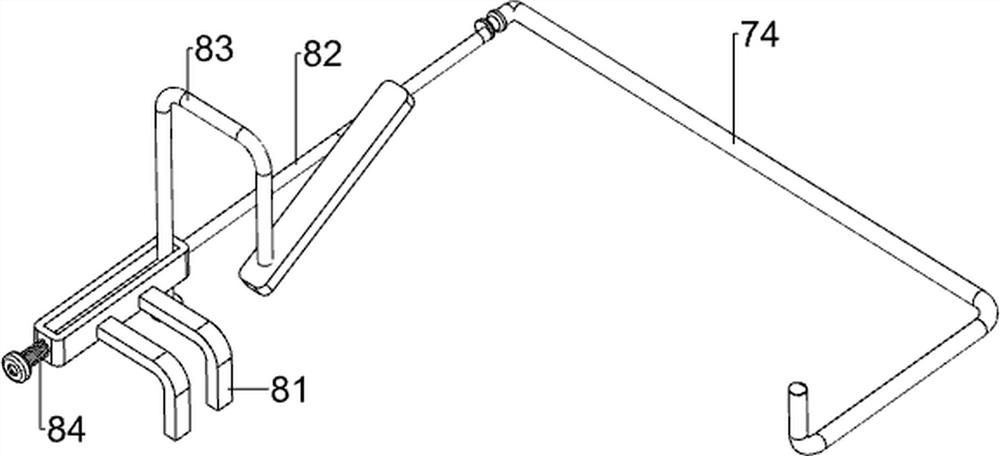

[0070] On the basis of Example 2, such as Figure 4-7 As shown, a compression mechanism 6 is also included, and the compression mechanism 6 includes a third fixed rod 61, a presser 62, a second spring 63 and a first rectangular frame 64, and the front side of the top of the chip rack 3 is provided with a third fixed Rod 61, on the third fixed rod 61 sliding type is provided with press-down device 62, and the bottom of press-down device 62 is positioned in the chip loading frame 3, and the second spring 63 is wound around the top of press-down device 62, and the top of second spring 63 and press down connected to the device 62, the bottom end of the second spring 63 is connected to the third fixed rod 61, and the top of the press device 62 is provided with a first rectangular frame 64.

[0071] After the aluminum shavings are thinned, before the feeder 53 is pushed forward, people press down the first rectangular frame 64, and the first rectangular frame 64 drives the presser 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com