Heating cable

A technology of heating cables and heating conductors, applied in the direction of electrical components, heating element shapes, magnetic field/electric field shielding, etc., can solve the problems of low leakage protection, low heat utilization rate, unfavorable large-area laying, etc., and achieve a safety factor Improvement, reduction of time, and the effect of temperature stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

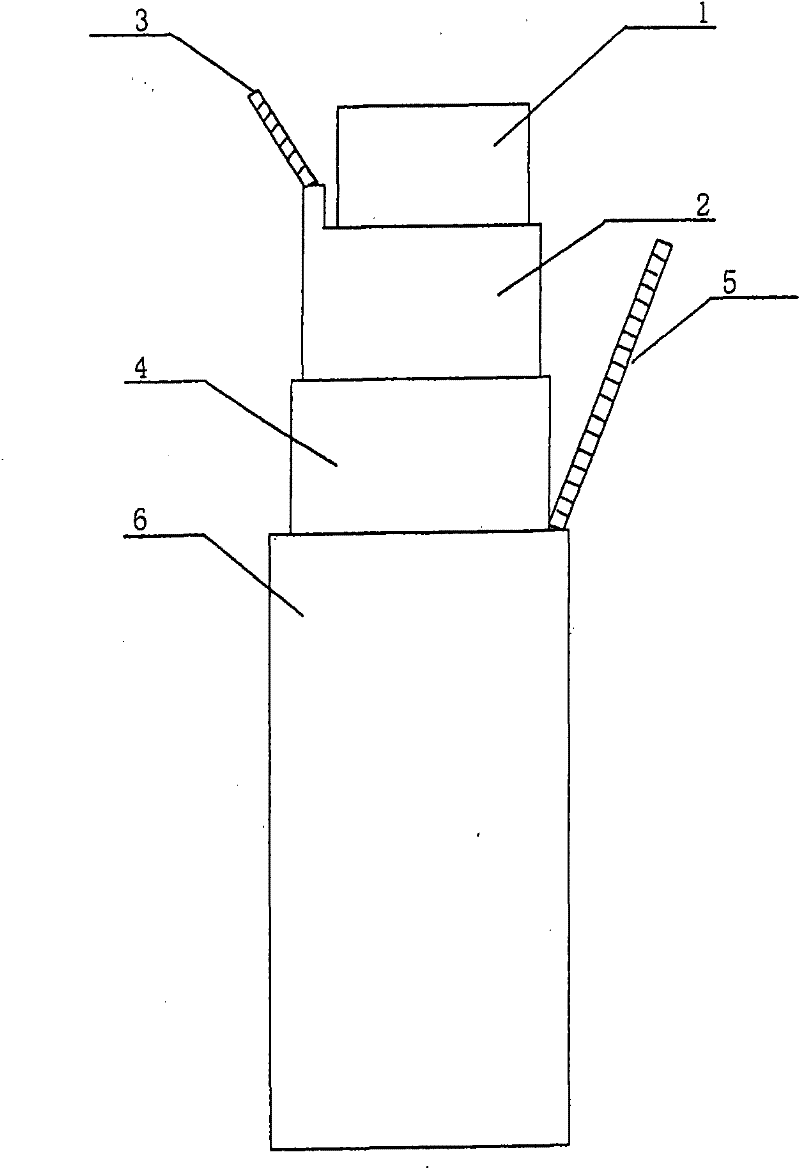

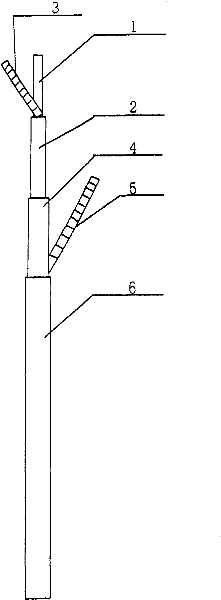

[0048] Such as figure 1 , figure 2 As shown, it is a heating cable with double ground wires and shielding.

[0049] A single row of ultra-thin chrome-aluminum or chromium-nickel alloy steel strip conductor 1, inner insulation layer 2, insulating layer connected ground wire 3, shielding 4, ground wire 5 between the shielding layer and the outer sheath, and outer sheath 6.

[0050] Use width mm×thickness mm=25×0.02 alloy steel strips containing 21% chromium, 6% aluminum or 20% chromium and 35% nickel as the conductor 1, and use flame-retardant polyvinyl chloride with a thickness of 0.3-0.5mm Plastic or cross-linked polyethylene plastic or fluorine plastic or silicone rubber plastic as the inner insulating layer 2, and a 7 / 0.2mm diameter copper stranded wire is installed in one piece next to the insulating layer as the ground wire 3, and the thickness is 0.02 ~ 0.05mm lamination film Aluminum foil material or 0.01-0.05mm laminated copper foil is used as the shielding layer 4, ...

Embodiment 2

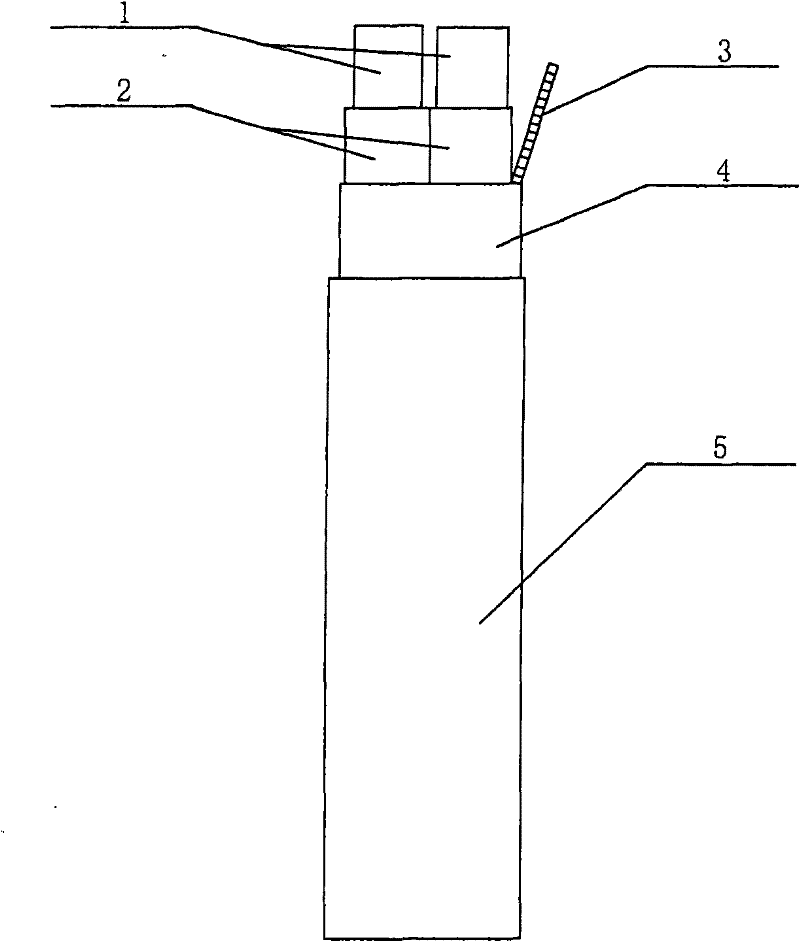

[0062] Such as image 3 , Figure 4 As shown, a heating cable with one ground wire and two heating conductors.

[0063] Double-row ultra-thin chrome-aluminum or chromium-nickel alloy steel strip conductor 1, insulation layer 2, ground wire 3, laminated copper foil shield 4, and outer sheath 5.

[0064] Two strips of width mm×thickness mm=4×0.05 are used side by side, and alloy steel strips containing 21% chromium, 6% aluminum or 20% chromium and 35% nickel are used as conductors 1, and resistance wires with a thickness of 0.3-0.5mm are used. Fired polyvinyl chloride plastic or cross-linked polyethylene plastic or fluorine plastic or silicone rubber plastic as the inner insulating layer 2, install a copper strand with a diameter of 7 / 0.2mm as the ground wire 3 next to the insulating layer, and adopt a thickness of 0.02 to 0.05mm Laminated aluminum foil material or 0.01-0.05mm laminated copper foil is used as the shielding layer 4, and flame-retardant polyvinyl chloride plasti...

Embodiment 3

[0067] Such as Figure 5 , Figure 6 As shown, a heating cable with ground wire and shielding.

[0068] A single row of ultra-thin chromium-aluminum or chromium-nickel alloy steel strips is used for conductor 1, inner insulating layer 2, shielding 3, outer sheathing 4, and ground wire 5 between the shielding layer and the outer sheathing.

[0069] Use width mm×thickness mm=10×0.05 alloy steel strips containing 21% chromium, 6% aluminum or 20% chromium and 35% nickel as the conductor 1, and use flame-retardant polyvinyl chloride with a thickness of 0.3-0.5mm Plastic or cross-linked polyethylene plastic or fluoroplastic or silicon rubber plastic is used as the inner insulating layer 2, and the thickness of 0.02-0.05mm is used as the laminated aluminum foil material or 0.01-0.05mm laminated copper foil is used as the shielding layer 3, and the thickness is 0.3-0.3mm 0.5mm flame-retardant polyvinyl chloride plastic or fluorine plastic or silicon rubber plastic is used as the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com