A railway track mobile maintenance workshop

A technology for repairing workshops and railway tracks, applied in tracks, laying tracks, railway transportation, etc., can solve the problems of low efficiency and high work intensity, and achieve the effects of reducing space occupation, increasing operating intervals, and reasonable design.

Active Publication Date: 2022-05-31

CHINA RAILWAY CONSTR HEAVY IND

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In recent years, rail transportation has achieved rapid development in China. The national railway operating mileage has exceeded 120,000 kilometers. With the long-term use of railway track lines, the demand for inspection and maintenance of railway lines is increasing. Fixed equipment toggle equipment, relying on manual transportation, high work intensity and low efficiency; there is no integrated equipment for the maintenance of railway track lines and fasteners in the industry, so a railway track mobile maintenance workshop is urgently needed in the industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

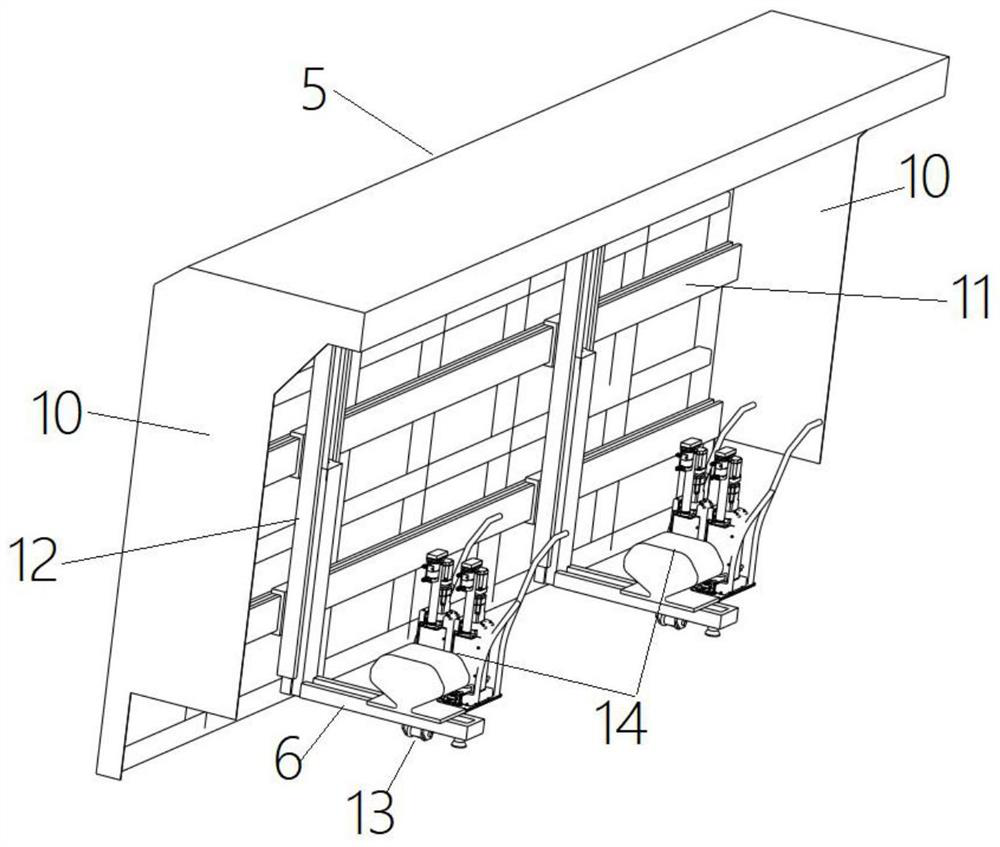

[0034] The application device a kind of two side walls used for the orbital mobile maintenance workshop to be slidably connected to the vehicle body using a telescopic sleeve,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

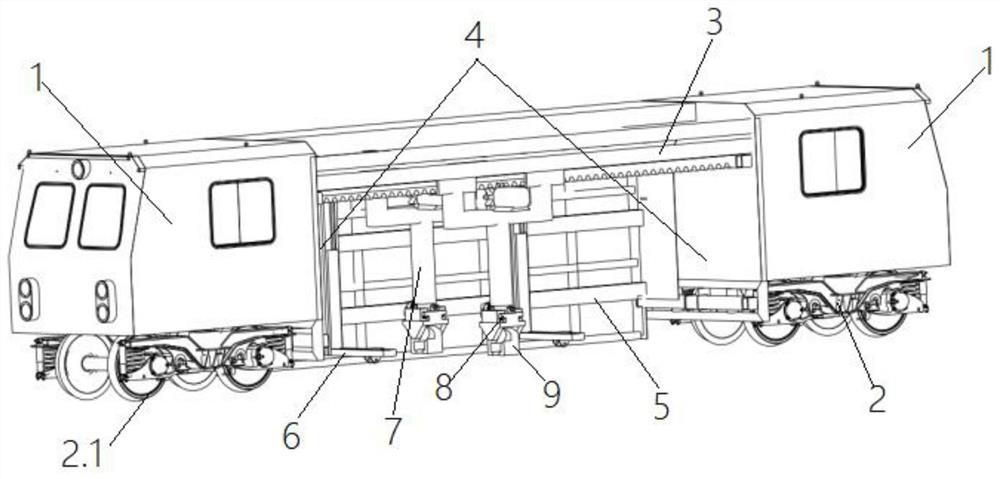

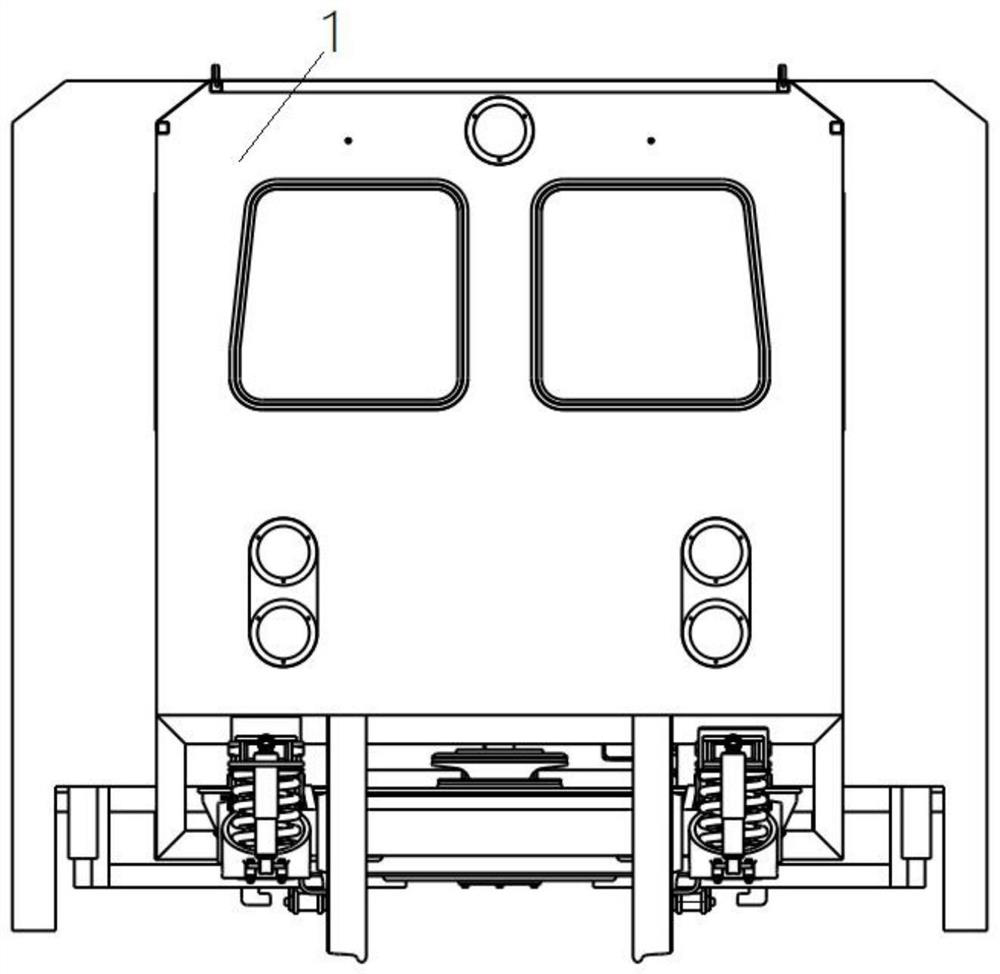

The invention provides a railway track mobile maintenance workshop, which includes a car body, a side wall, a bolt tightening device and a lifting device; Both cabs can control the driving of the maintenance workshop. The cabs at both ends are connected by frame beams at the upper ends, and the cabs at both ends are hollow, providing installation space for bolt tightening devices and lifting devices and operating space for staff, which is convenient for manual labor. Operation operation, at the same time, the bolt tightening device uses the first sliding module and the second sliding module on the side wall to realize the position movement along the length direction and height direction of the vehicle body, and realizes the vehicle body movement by using the first chute set on the first bracket. The position moves in the width direction of the body, and the three directions are coordinated to move to the fastener of the rail to loosen or tighten the bolt; and use the pulling device at the end of the telescopic bracket to lift the rail to realize the position adjustment of the railway track and the replacement of the fastener.

Description

A railway track mobile maintenance workshop technical field The present invention relates to the maintenance technical field of railway track lines, be specifically related to a kind of railway track mobile maintenance vehicle between. Background technique [0002] In recent years, rail transit has achieved rapid development in China, and the national railway operating mileage has exceeded 120,000 kilometers. With the long-term application of railway track lines, the demand for railway line inspection and maintenance is increasing. At present, the maintenance of rails and fasteners is usually Using small fastening equipment to move the equipment, relying on manual moving and transportation, the work intensity is high and the efficiency is low; there is no one in the industry for iron An integrated equipment for the maintenance of rails and fasteners for road and rail lines, so the industry is in urgent need of a mobile repair workshop for railway tracks. SUMMARY OF T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01B29/16E01B31/18

CPCE01B29/16E01B31/18Y02T30/00

Inventor 刘飞香罗建利胡斌张明朱震寰乔宗原

Owner CHINA RAILWAY CONSTR HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com