Automatic plastic equipment for garden shear handle for garden pruning

A technology for gardening and scissors is applied in the field of automatic plastic equipment for gardening scissors for garden pruning, which can solve the problems of slow speed of scissors and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

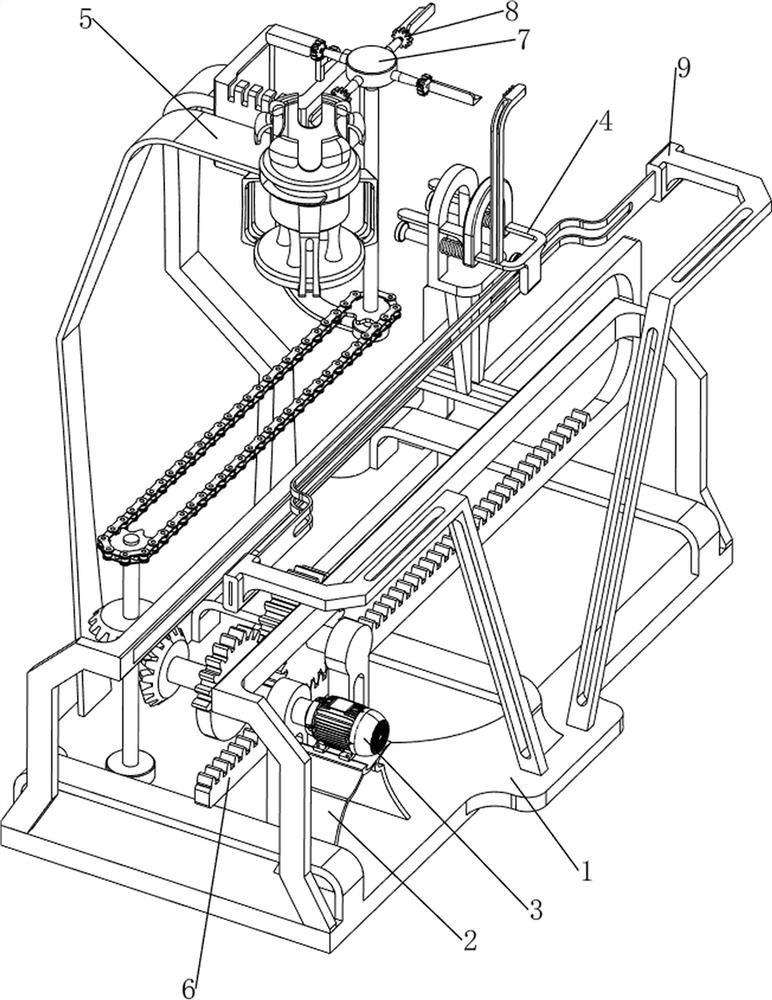

[0028] A kind of automatic plastic equipment with garden scissor handle for garden pruning, such as figure 1 As shown, it includes a base plate 1, a support frame 2, a motor 3, a clamping mechanism 4 and a feeding mechanism 5, a support frame 2 is provided on the left front side of the upper part of the base plate 1, a motor 3 is provided on the upper part of the support frame 2, and a motor 3 is provided on the upper part of the base plate 1. The clamping mechanism 4 is provided with a blanking mechanism 5 on the rear side of the upper part of the bottom plate 1 .

[0029] When the user needs to make plastic scissor handles, this equipment can be used. Firstly, the mold is placed in the clamping mechanism 4 for fixing, and then the clamping mechanism 4 is moved to directly below the blanking mechanism 5, and the mold is adjusted by the blanking mechanism 5. Carry out blanking, after the blanking is completed, just wait for the plastic to be completed.

Embodiment 2

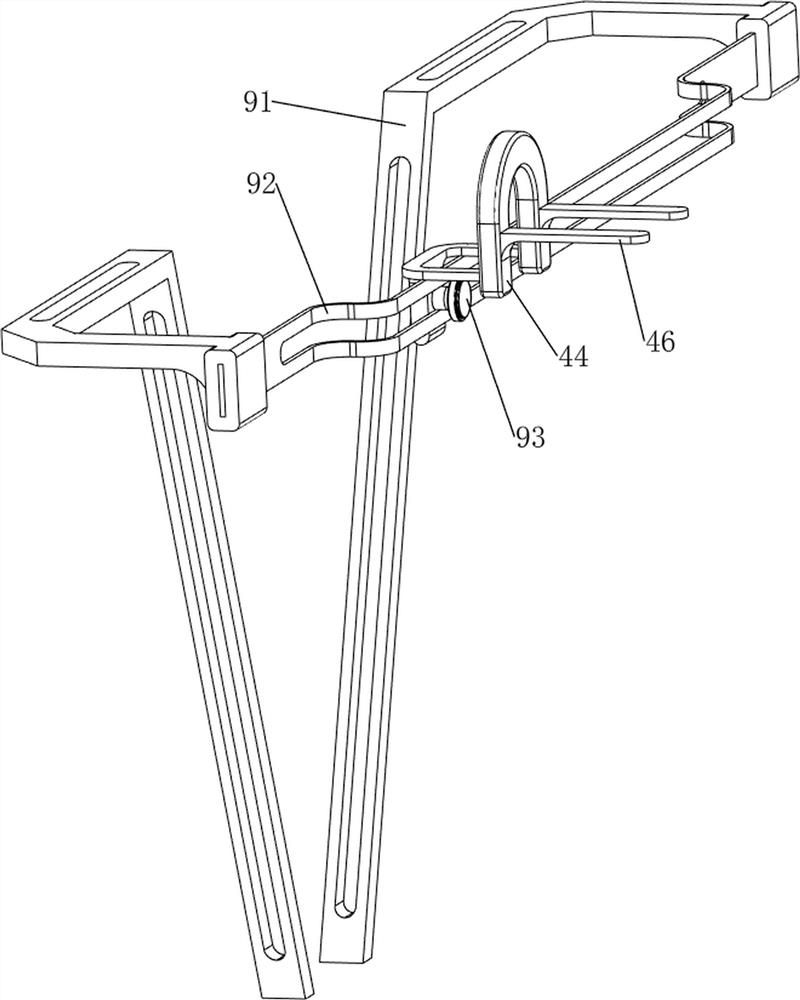

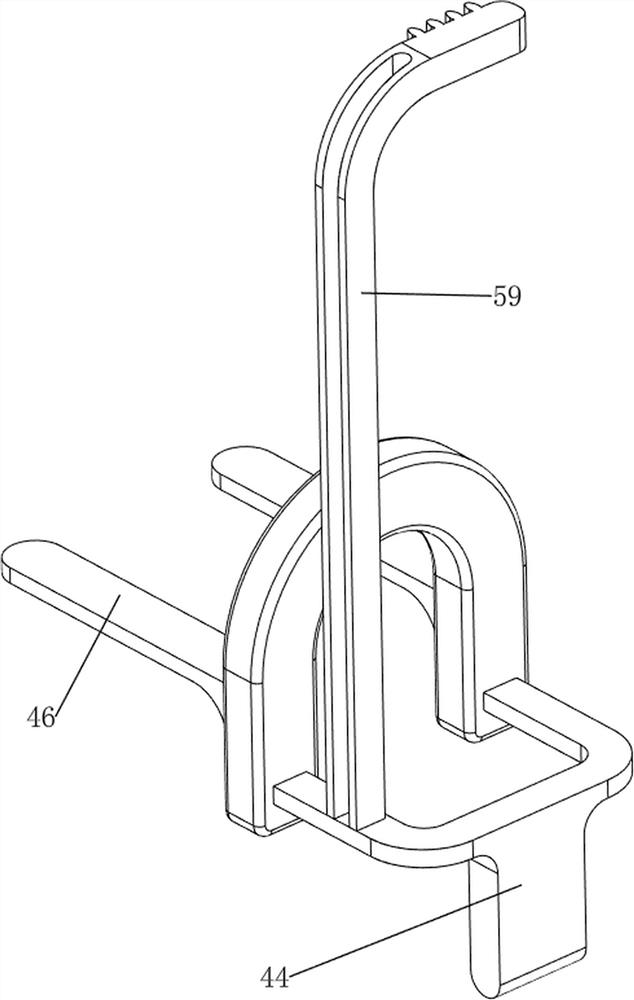

[0031] On the basis of Example 1, such as Figure 2-4 As shown, the clamping mechanism 4 includes a square slide rail 41, a first slider 42, a fixing fixture 43, a pressure plate 44, a telescopic assembly 45 and a first pallet 46, and the upper part of the bottom plate 1 is symmetrically provided with a square slide rail 41, A first slide block 42 is slidably provided between the square slide rails 41, a fixing fixture 43 is provided on the top of the first slide block 42, a first supporting plate 46 is slidably provided on the fixing fixture 43, and a Pressing plate 44, fixed fixture 43 slide type is provided with telescopic assembly 45, and telescopic assembly 45 is made up of connecting rod and compression spring, and connecting rod is slidably connected with fixing fixture 43, and compression spring is connected with fixing fixture 43 and first supporting plate 46, The telescopic assembly 45 is connected with the pressing plate 44 .

[0032] The user pulls the pressing pl...

Embodiment 3

[0036] On the basis of Example 2, such as Figure 5-8As shown, the feeding mechanism 6 also includes a first fixed column 61, a second rotating shaft 62, a missing gear 63, a second fixed column 64, a third rotating shaft 65, a second spur gear 66 and a second rack 67, and the bottom plate 1. A first fixed column 61 is provided on the left front side of the upper part, and a second rotating shaft 62 is rotatably provided on the first fixed column 61. The second rotating shaft 62 is connected with the output shaft of the motor 3. A missing gear 63 is provided on the second rotating shaft 62. The left front side of the bottom plate 1 top is provided with a second fixed column 64, on which the second fixed column 64 is rotatably provided with a third rotating shaft 65, on which the third rotating shaft 65 is provided with a second spur gear 66, the second spur gear 66 and the missing gear 63 Cooperating, the second rack 67 is connected to the first slider 42 , and the second rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com