Industrial steel pipe bending device

A bending device, industrial technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of failure to realize automatic discharge, and achieve the effect of reducing the time of manual receiving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

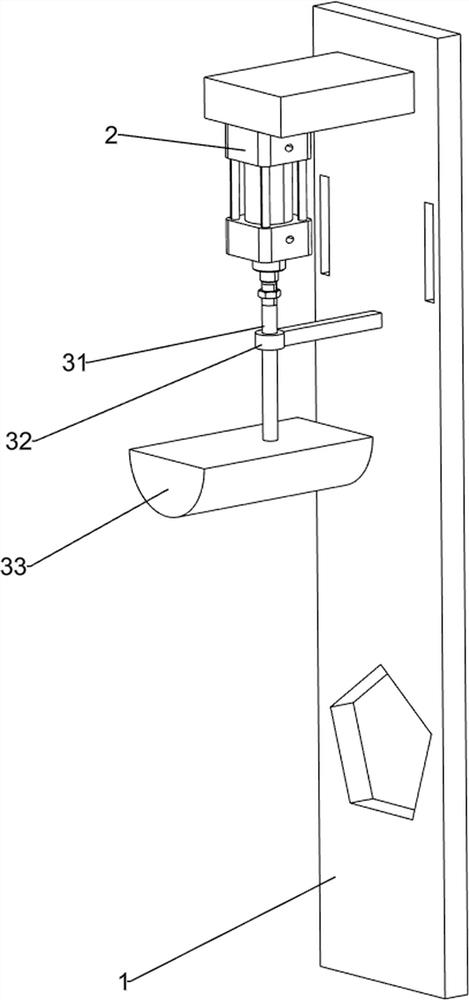

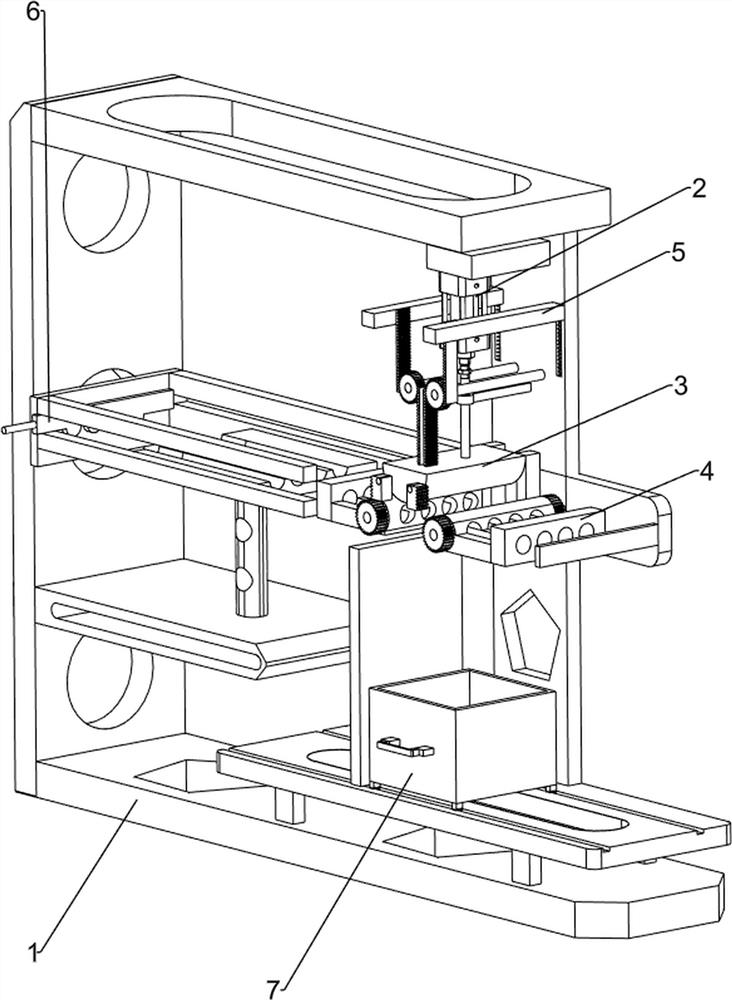

[0027] An industrial steel pipe bending device, such as figure 1 As shown, it includes a first support frame 1, a cylinder 2, a pressing mechanism 3 and a bending mechanism 4, the upper right side of the first support frame 1 is equipped with a cylinder 2, and the upper right side of the first support frame 1 is connected with the cylinder 2. A pressing mechanism 3 is arranged between them, and a bending mechanism 4 is arranged between the middle of the right part of the first support frame 1 and the pressing mechanism 3 .

[0028] When people need to bend steel pipes, this industrial steel pipe bending device can be used. First, people need to put the steel pipes into the bending mechanism 4, then start the cylinder 2, and the telescopic rod of the cylinder 2 moves up and down to drive the pressing mechanism 3 Move up and down, bend the steel pipe, close the cylinder 2 after bending, and people can collect it on the lower side.

Embodiment 2

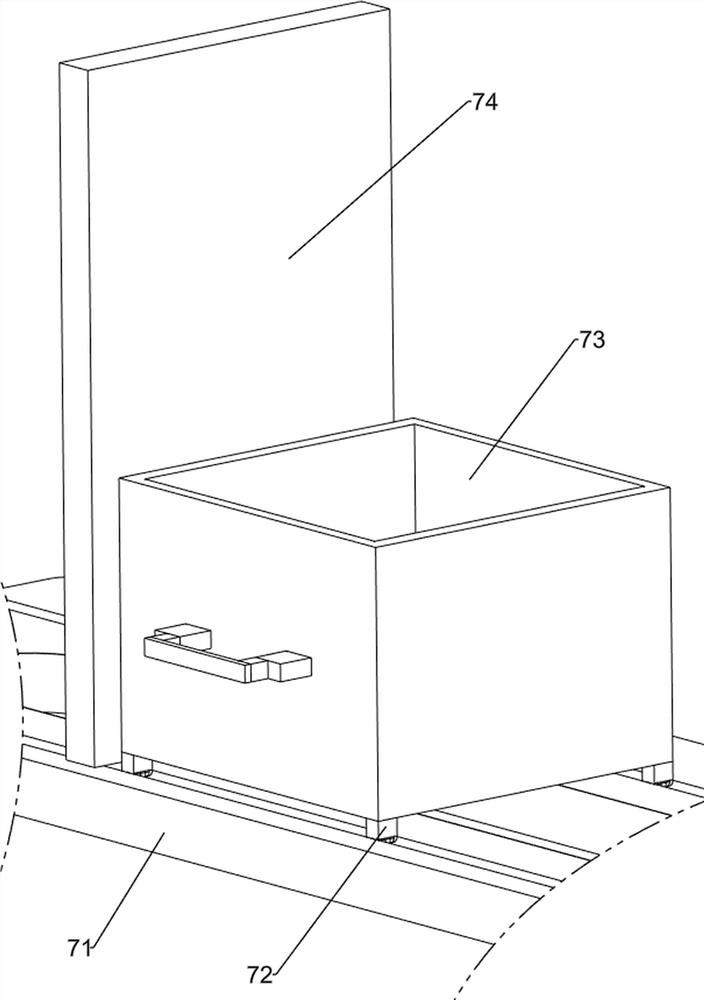

[0030] On the basis of Example 1, such as Figure 2-Figure 6 As shown, the pressing mechanism 3 includes a first support column 31, a spacer 32 and a U-shaped hammer 33. The upper side of the right part of the first support frame 1 is provided with a spacer 32, and the front side of the spacer 32 is slidingly provided with a The first support column 31, the top of the first support column 31 is connected with the telescopic rod of the cylinder 2, and the bottom of the first support column 31 is provided with a U-shaped hammer 33.

[0031] People put the steel pipe in the bending mechanism 4, then start the cylinder 2, and the telescopic rod of the cylinder 2 moves downward to drive the first support column 31 to move downward, thereby driving the U-shaped hammer 33 to move downward to press down on the steel pipe. When the telescoping link of cylinder 2 moves upwards and drives first support column 31 to move upwards, first support column 31 drives U-shaped hammer 33 to move u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com