Lifting type crushing equipment for flour processing

A kind of crushing equipment, lift-type technology, applied in the field of lift-type crushing equipment for flour processing, can solve problems such as poor crushing effect, complicated structure and difficult operation for staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

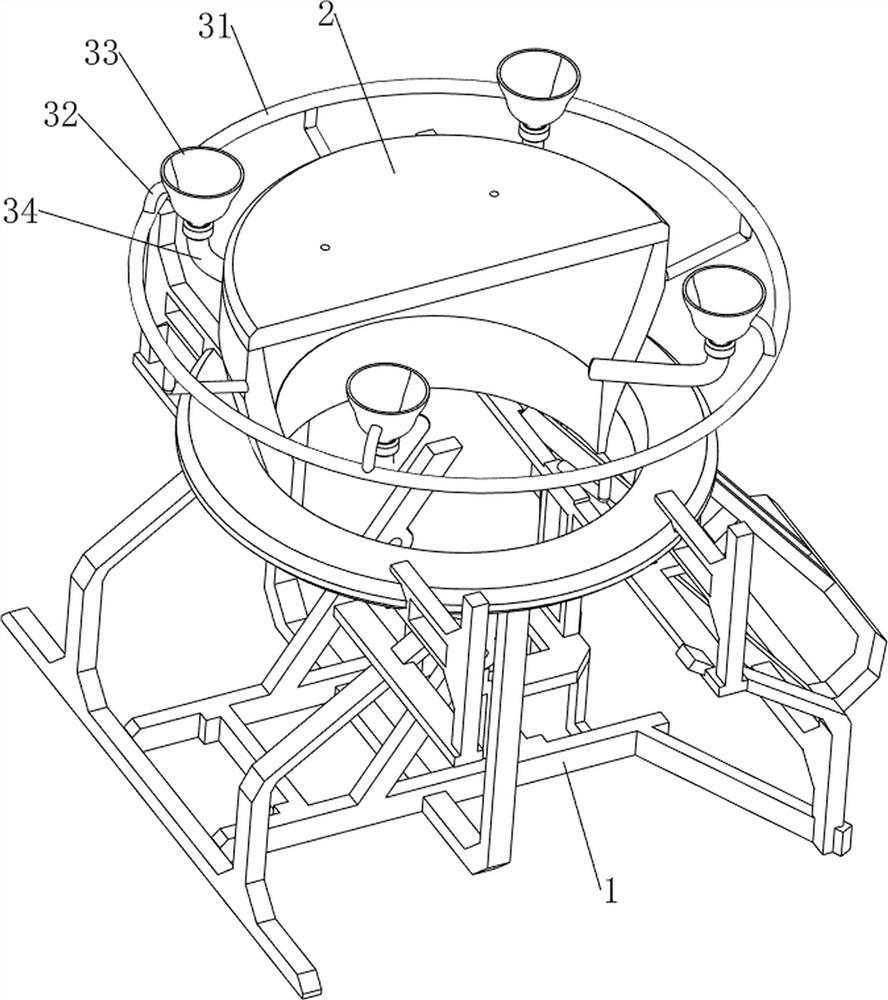

[0071] A lifting type crushing equipment for flour processing, such as Figure 1-Figure 3 As shown, it includes a support frame 1, a processing barrel 2, a material guide mechanism 3, a feeding mechanism 4 and a crushing mechanism 5. The support frame 1 is provided with a processing barrel 2, and the upper and outer walls of the processing barrel 2 are provided with a material guide mechanism 3. A blanking mechanism 4 is provided between the bottom of the processing barrel 2 and the support frame 1, and a crushing mechanism 5 is provided on the blanking mechanism 4.

[0072] When people need to grind flour, they can use this lifting type grinding equipment for flour processing. First, people need to pour the flour into the material guide mechanism 3, so that the flour falls onto the material feeding mechanism 4 through the material guide mechanism 3, and then Put the collection frame under the feeding mechanism 4, and then start the crushing mechanism 5, the crushing mechanism...

Embodiment 2

[0074] On the basis of Example 1, such as Figure 4-Figure 6 As shown, the material guide mechanism 3 includes a fixed ring 31, a first connecting rod 32, a material guide hopper 33 and a material guide pipe 34. The upper and outer walls of the processing barrel 2 are provided with a fixed ring 31, and the front and rear sides of the top of the fixed ring 31 are evenly spaced. There are two first connecting rods 32, the first connecting rods 32 on the front and rear sides are all provided with a guide hopper 33, and two feed pipes 34 are arranged at intervals on both sides of the front and back of the processing barrel 2, and the feed pipe 34 is the same as the same Side guide hopper 33 bottoms are fixedly connected.

[0075] People pour flour into the hopper 33, so that the flour flows onto the feed pipe 34 through the feed hopper 33, and falls from the feed pipe 34 into the feeding mechanism 4 to realize the effect of feeding.

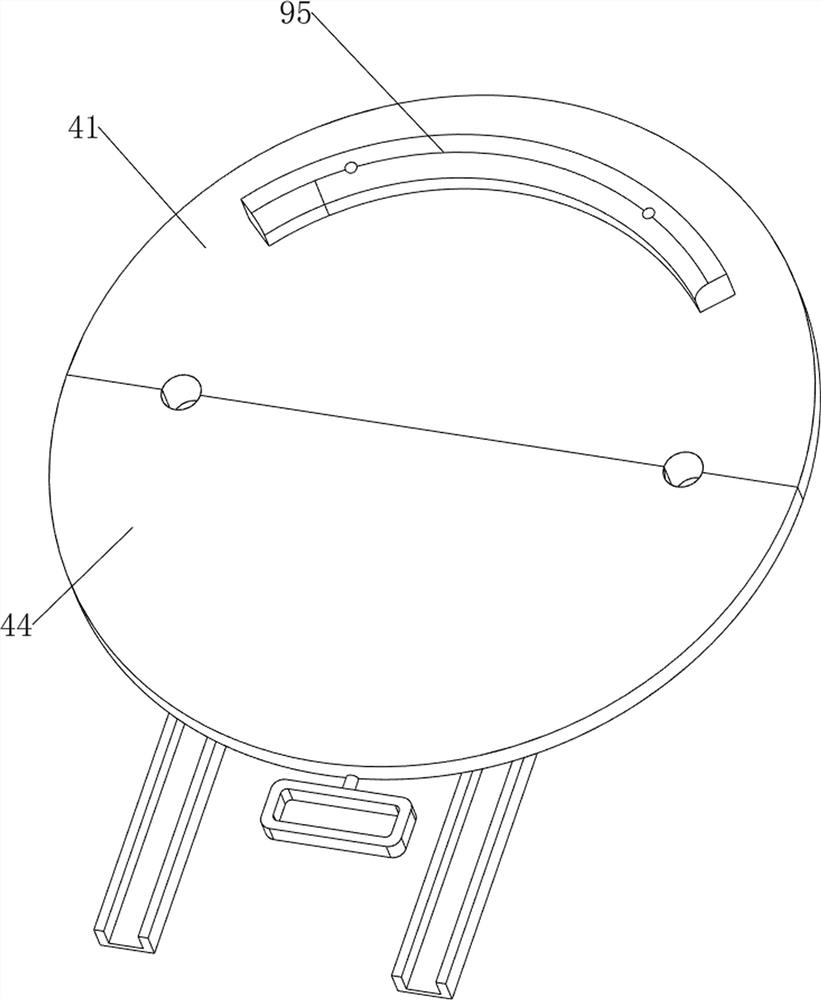

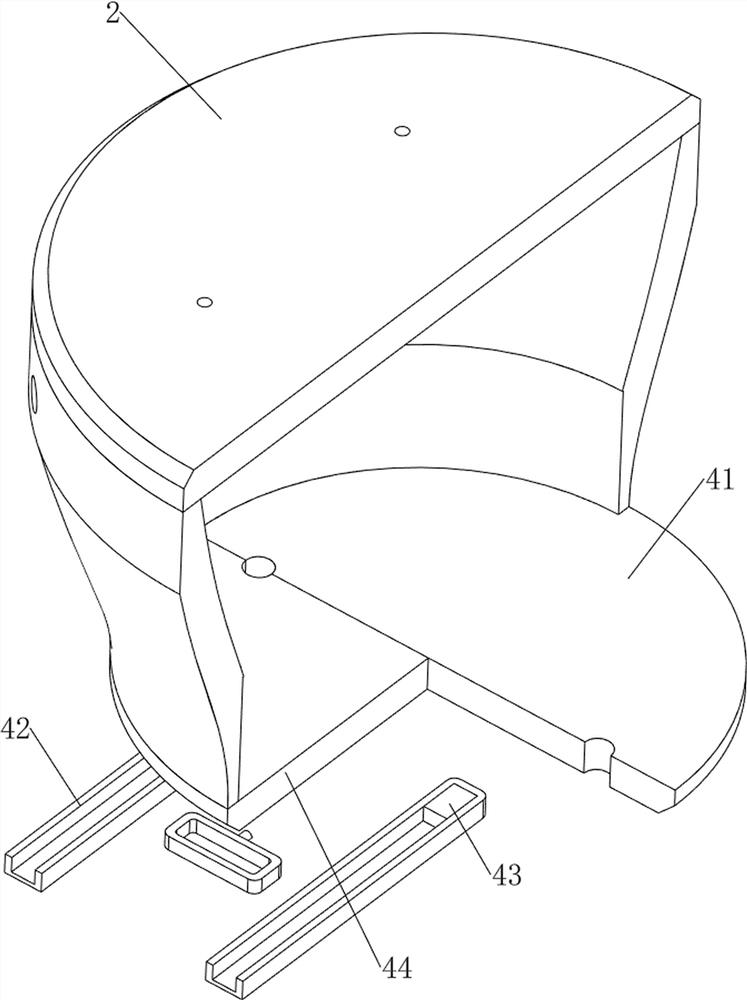

[0076] The blanking mechanism 4 includes a fi...

Embodiment 3

[0081] On the basis of Example 2, such as Figure 7-Figure 11 As shown, it also includes a retracting mechanism 6, and the retracting mechanism 6 includes a first fixed sleeve 61, a rotating shaft 62, a rotating plate 63 and a first spring 64, and the four sides of the inner wall of the processing barrel 2 are symmetrically provided with the first fixed sleeve 61. Rotational shaft 62 is provided between the two first fixed sleeves 61 on the side, and rotating shaft 62 is provided with rotating plate 63. Two ends of the spring 64 are respectively connected with the first fixing sleeve 61 and the rotating plate 63 .

[0082] When the sliding frame 53 moves downward, the sliding frame 53 makes the inner side of the rotating plate 63 rotate outward, and the outer side of the rotating plate 63 rotates inward, so that the rotating shaft 62 rotates, and the first spring 64 is torsionally deformed. When the sliding frame 53 moves upward, Because the first spring 64 resets, the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com