Multistage sieving machine for high-reflectivity powder paint sieve residue measuring

A technology of powder coating and high reflectivity, applied in the direction of filter screen, special scale, solid separation, etc., can solve the problems of high risk factor, less screening times, poor shockproof effect, etc., and achieve the effect of collection and rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

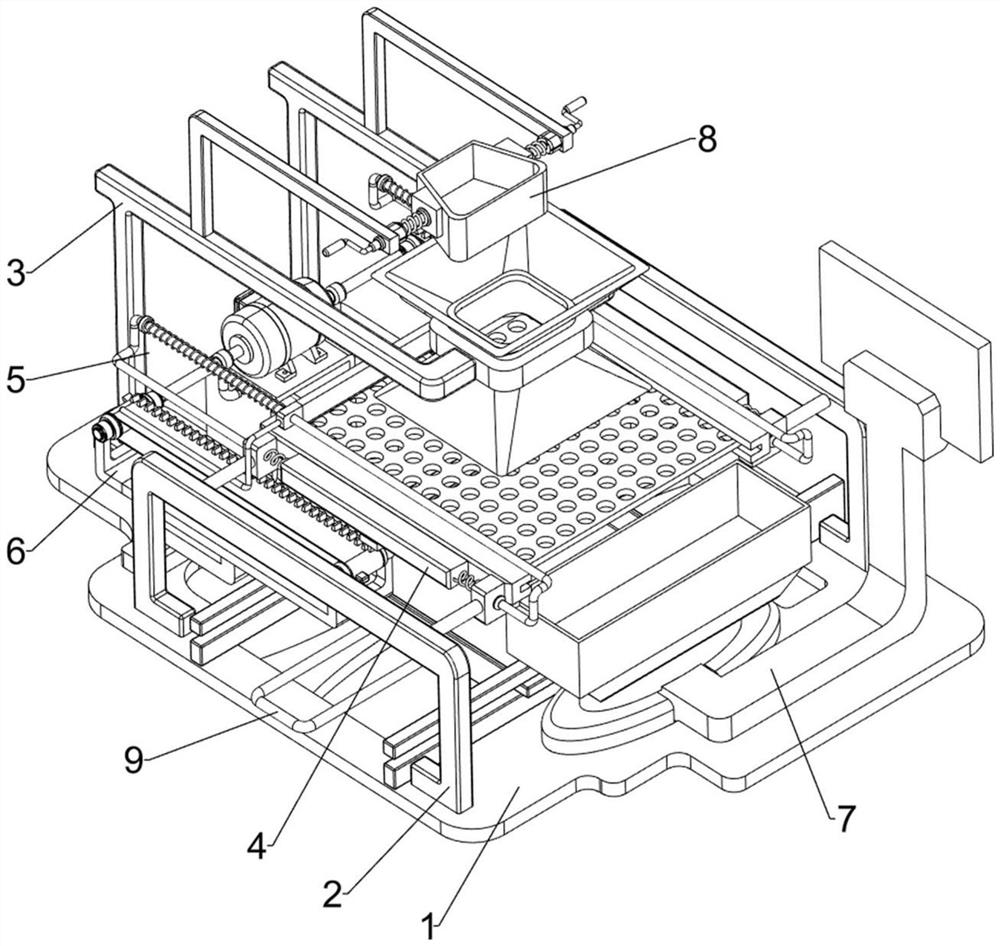

[0059] A multi-stage sieving machine for the determination of sieve residues of high-reflectance powder coatings, such as figure 1 As shown, it includes a base plate 1, a first mounting frame 2, a second mounting frame 3, a screening mechanism 4 and a push-out mechanism 5, the left and right sides of the base plate 1 are provided with the first mounting frame 2, and the left and right sides of the upper rear side of the base plate 1 Each part is provided with a second mounting frame 3, and a screening mechanism 4 is connected between the two first mounting frames 2, and a pushing mechanism 5 is arranged on the screening mechanism 4.

[0060] When people want to measure high-reflectance powder coatings, they can use this multi-stage sieving machine for the determination of sieve residues of high-reflectance powder coatings. First, users mix high-reflectance powders with a certain proportion of water to form High-reflectance powder coating, then pour the high-reflectance powder ...

Embodiment 2

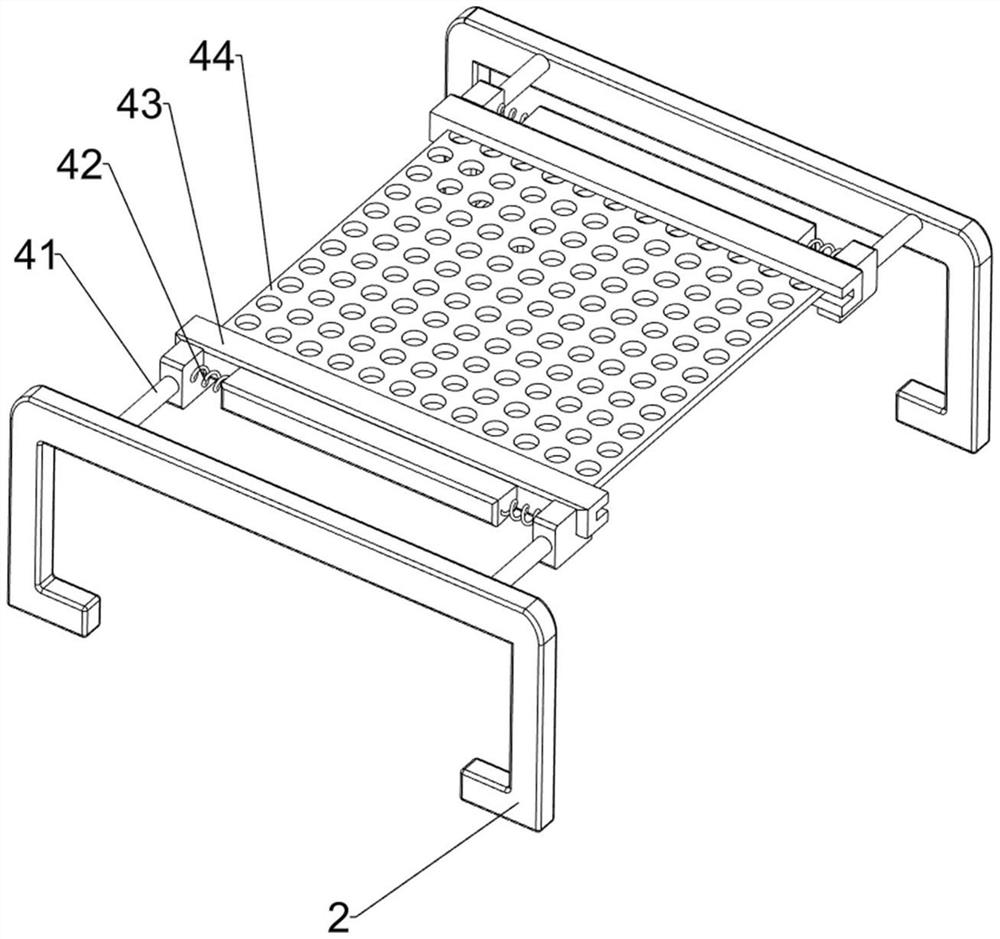

[0062] On the basis of Example 1, such as figure 2 and image 3 As shown, the screening mechanism 4 includes a support block 41, a first spring 42, a clip 43 and a sieve plate 44. The first mounting frame 2 is provided with a support block 41. The number of support blocks 41 is four, and two on the same side A clamping block 43 is slidably connected between the supporting blocks 41 , a first spring 42 is connected between the clamping block 43 and the supporting block 41 , and a sieve plate 44 is connected between the two clamping blocks 43 .

[0063]The user pours the prepared high-reflectivity powder paint onto the sieve plate 44, and the high-reflectivity powder paint is attached to the sieve plate 44, and then pushes the clamping block 43 forward, and the clamping block 43 drives the sieve plate 44 to move forward. The first spring 42 on the side is compressed, the first spring 42 on the rear side is stretched, and the clamp block 43 is pushed backward, the clamp block 4...

Embodiment 3

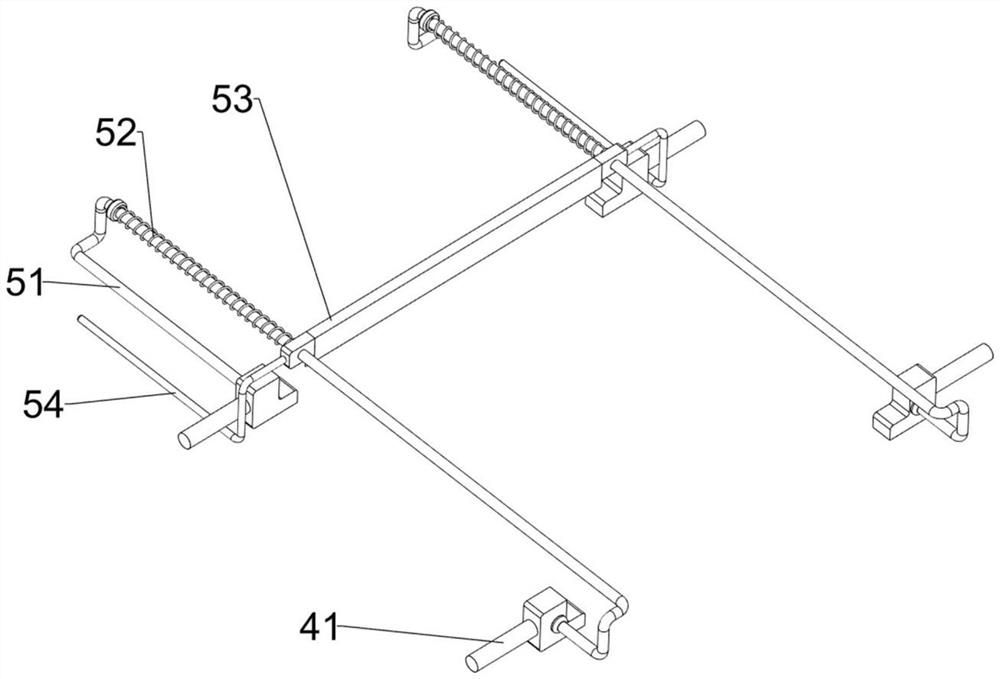

[0067] On the basis of Example 2, such as Figure 4-Figure 7 Shown, also comprise rotating mechanism 6, base plate 1 upper rear side is provided with rotating mechanism 6, and rotating mechanism 6 comprises base 61, motor 62, transmission shaft 63, support frame 64, belt pulley 65, special-shaped belt 66 and tooth bar 67 , base plate 1 upper rear side is provided with base 61, and base 61 top is equipped with motor 62, and base plate 1 is provided with support frame 64 on left and right sides, and support frame 64 upper part is equipped with transmission shaft 63 all front and back symmetrical rotation type, rear side Transmission shaft 63 is all connected with motor 62 output shafts, and belt pulley 65 is all provided on the transmission shaft 63, and special-shaped belt 66 is all connected between two belt pulleys 65 on the same side, and tooth bar 67 is all provided with two clamp blocks 43 bottoms, The toothed rack 67 engages with the toothed portion of the profiled belt 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com