Feed structure of air integrated waveguide

An integrated waveguide and feed technology, applied in the direction of the structure of the radiation element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

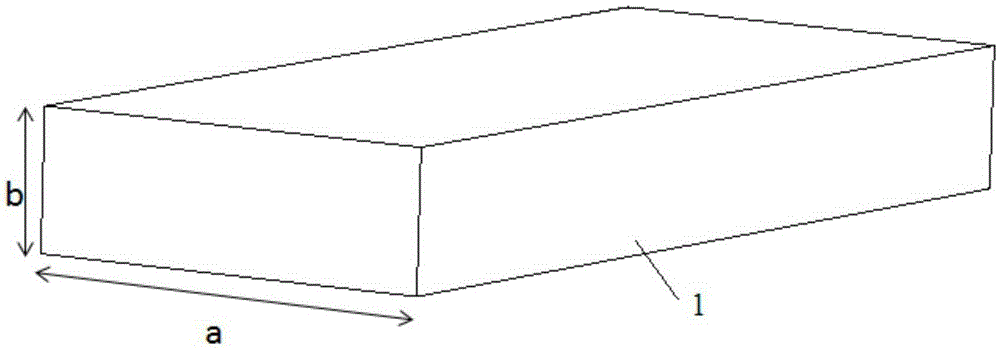

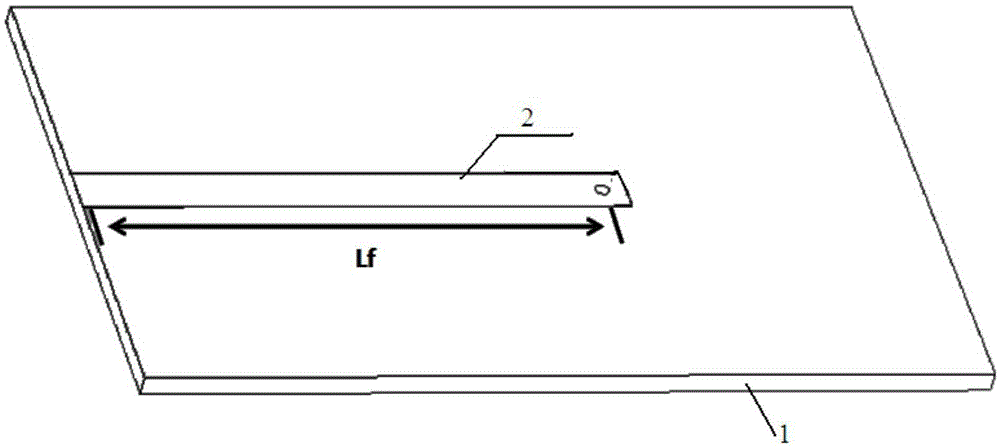

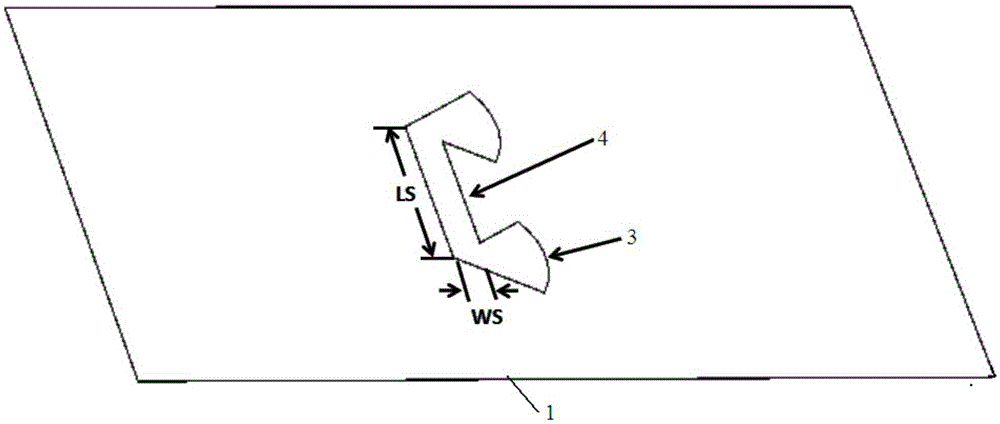

[0019] Specific implementation mode 1. Combination Figure 1 to Figure 5 Describe this embodiment mode, the feeding structure of an air-integrated waveguide described in this embodiment mode, which includes a rectangular waveguide plate 1, a microstrip line 2, a fan-shaped area 3, a coupling slot 4, a waveguide slot 5, a feed slot 6 and metal plate 7;

[0020] The upper surface of the rectangular waveguide plate 1 is engraved with a waveguide groove 5 and a feed groove 6, the depth of the feed groove is greater than the depth of the waveguide groove; the waveguide groove 5 is rectangular, and the feed groove 6 is arranged adjacent to the waveguide groove 5; Above the waveguide groove 5 and the feeding groove 6, and maintain electrical connection with the rectangular waveguide plate 1; the metal plate 7 forms the waveguide cavity and the feeding cavity with the waveguide groove 5 and the feeding groove 6; the waveguide cavity and the feeding cavity A feed structure is formed; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com