Multifunctional full-automatic rotary material taking and feeding mechanism

A fully automatic technology for retrieving and feeding materials, which is applied in the field of multi-functional automatic rotary retrieving and feeding mechanisms, can solve the problems of increasing manufacturing costs and maintenance costs, unfavorable enterprises to expand scale, and low processing accuracy, so as to reduce manufacturing costs and maintenance Cost, beneficial to the scale of the enterprise, and the effect of improving the processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

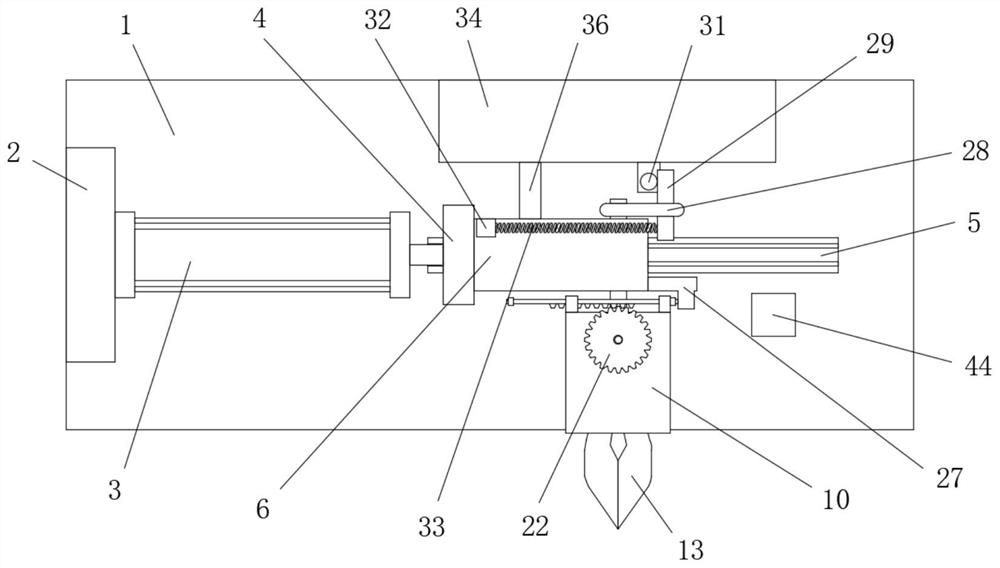

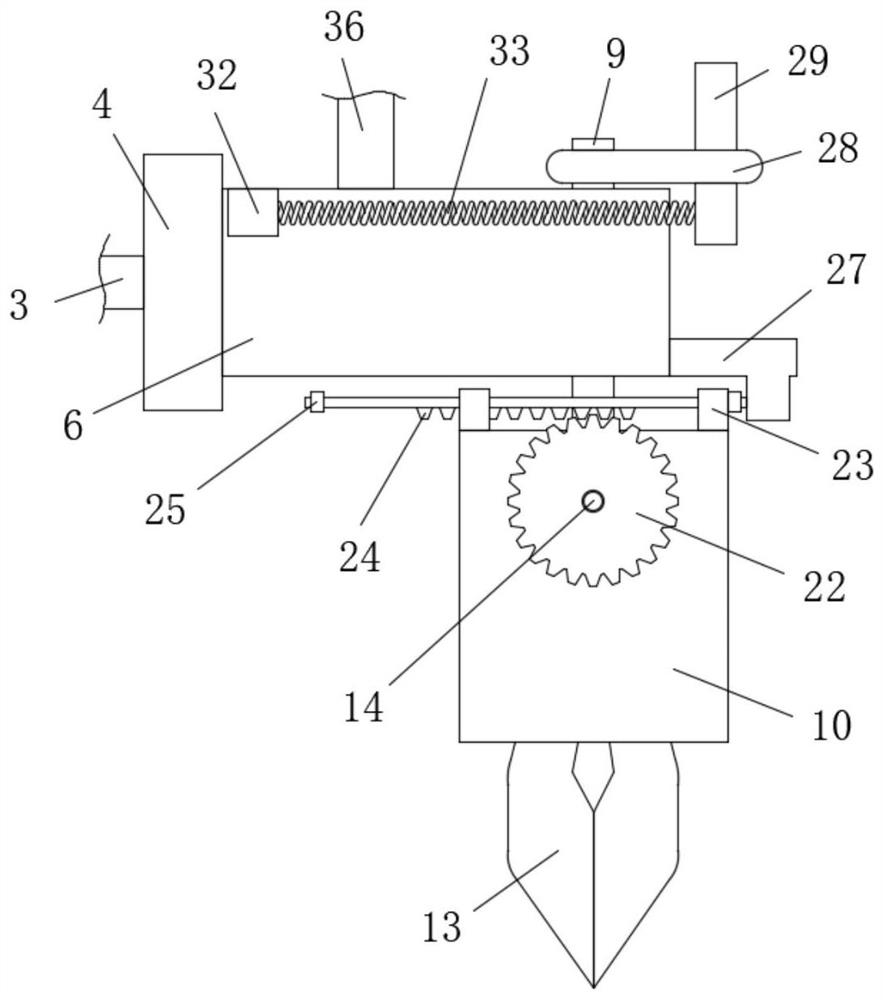

[0038] refer to Figure 1-12 , a multi-functional fully automatic rotary retrieving and feeding mechanism, including a base 1, the top of the base 1 is provided with a slide rail 5, the top side of the base 1 is fixedly connected with a mounting plate 2, and the side of the mounting plate 2 is close to the slide rail 5 A telescopic cylinder 3 is fixedly installed, and an L-shaped slide plate 4 is fixedly connected to the horizontal output shaft of the telescopic cylinder 3, and the bottom of the L-shaped slide plate 4 is slidably connected with the slide rail 5, and the side of the L-shaped slide plate 4 away from the telescopic cylinder 3 is provided There is a chute 43, a sliding seat 6 is slidably connected in the chute 43, one side of the sliding seat 6 extends to the outside of the L-shaped slide plate 4 and is rotatably connected with a rotating block 10, and the rotating block 10 is a hollow structure, and the rotating block 10 is away from One side of the sliding seat ...

Embodiment 2

[0040] Further improved on the basis of embodiment one:

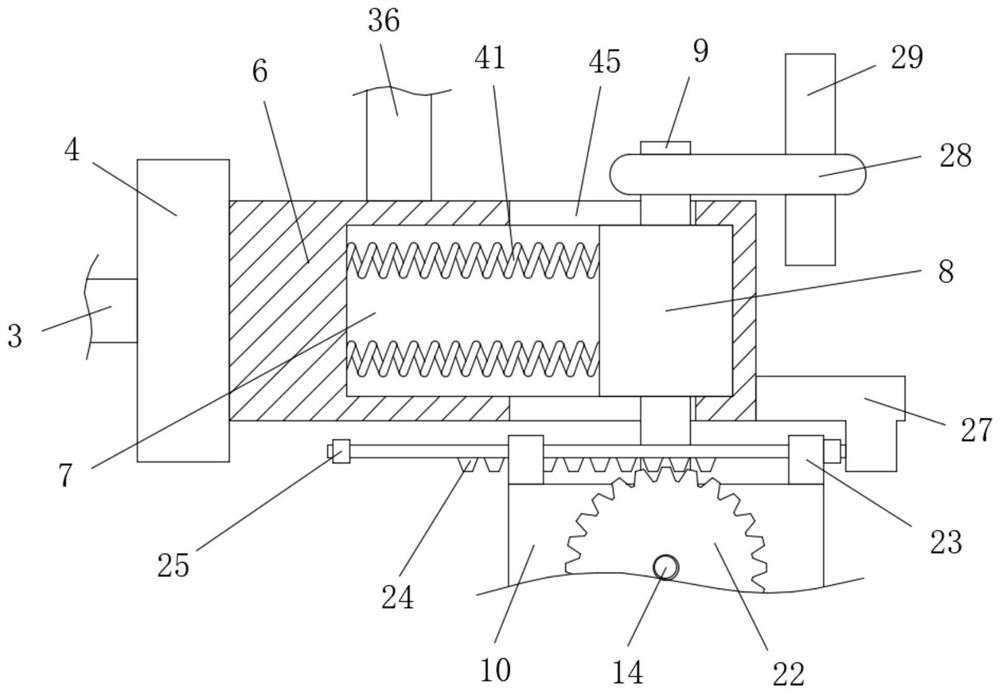

[0041] In the present invention, the inside of the sliding seat 6 is provided with a sliding chamber 7, and two sliding holes 45 are symmetrically provided on the side of the sliding seat 6 away from each other. The sliding chamber 7 is slidably connected with a slider 8. The side runs through and is connected with the first rotating rod 9, and one end of the first rotating rod 9 passes through the corresponding sliding hole 45 and is fixedly connected with the outer wall of the side of the rotating block 10 close to the sliding seat 6, and the other end of the first rotating rod 9 passes through the other side. A sliding hole 45 is connected with the transmission assembly, one side of the sliding block 8 is in contact with the inner wall of the side of the sliding chamber 7 away from the L-shaped slide plate 4, and the other side of the sliding block 8 is symmetrically fixedly connected with two second pullers. Stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com