Coating machine

A coating machine and coating technology, which is applied in the field of coating machines, can solve the problems that the battery case cannot be coated with glue, and the sealing ring cannot be fixed together with the battery case, so as to improve the glue coating effect, realize the material feeding effect, and coat the battery case. good glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

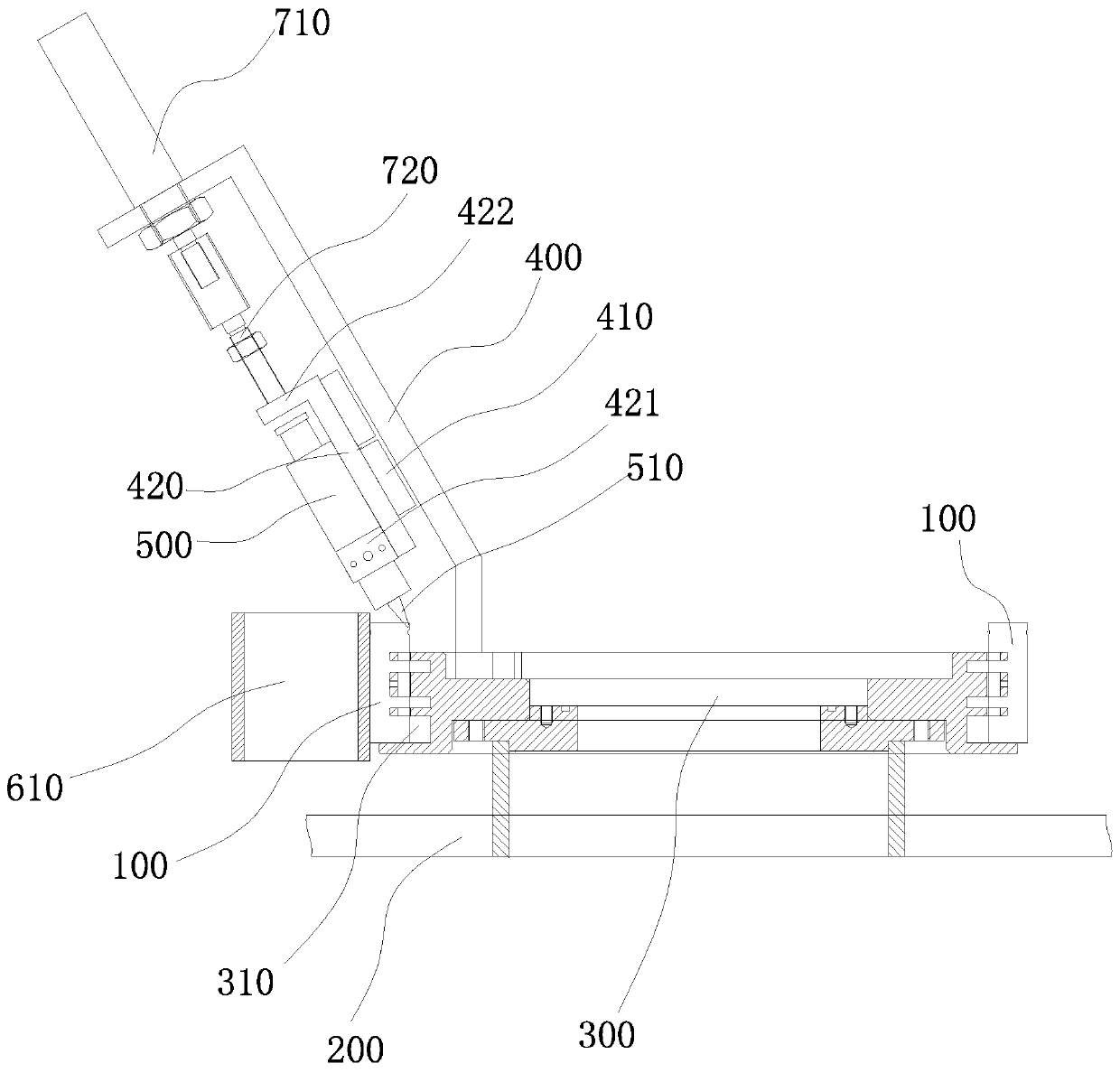

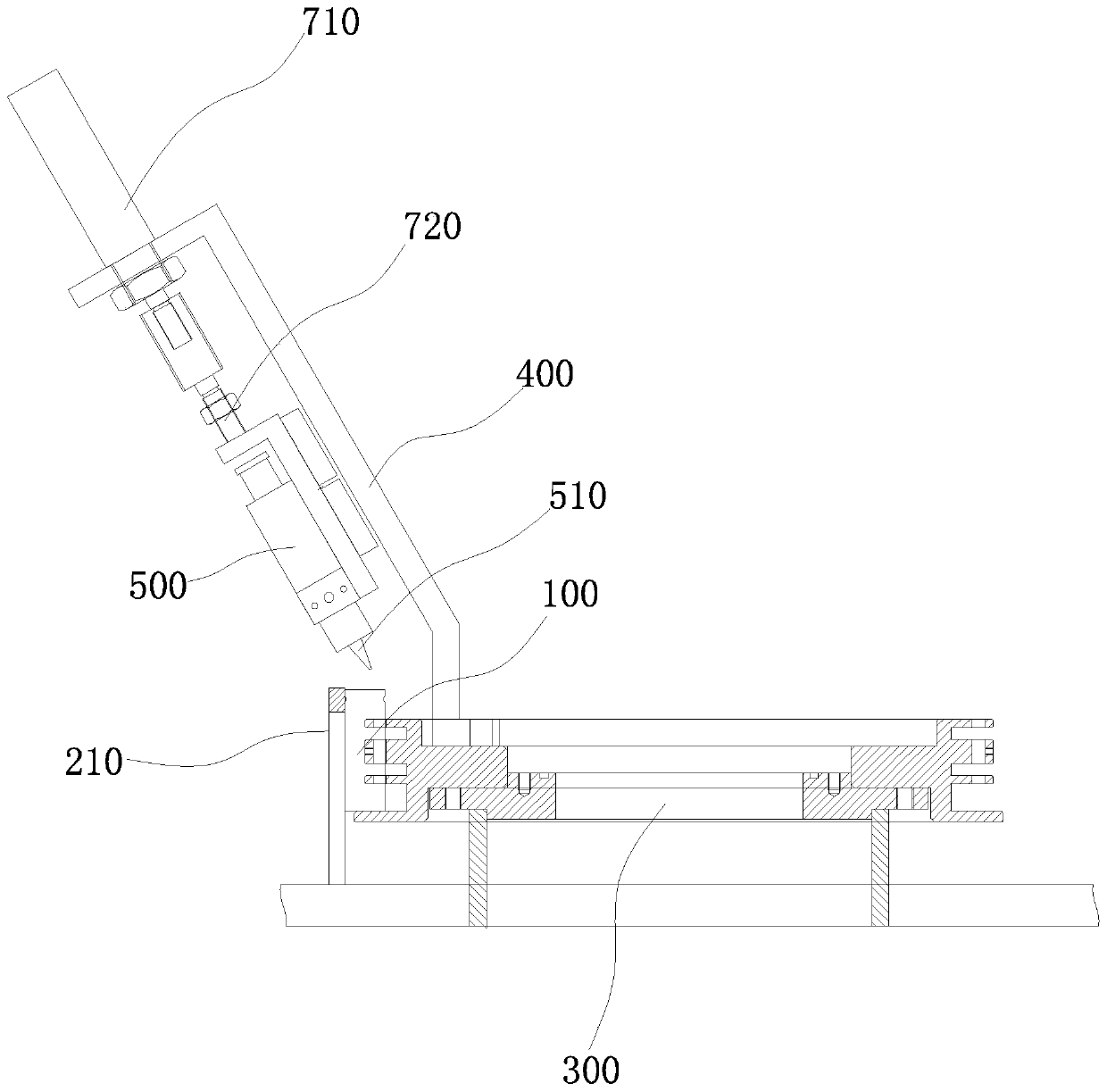

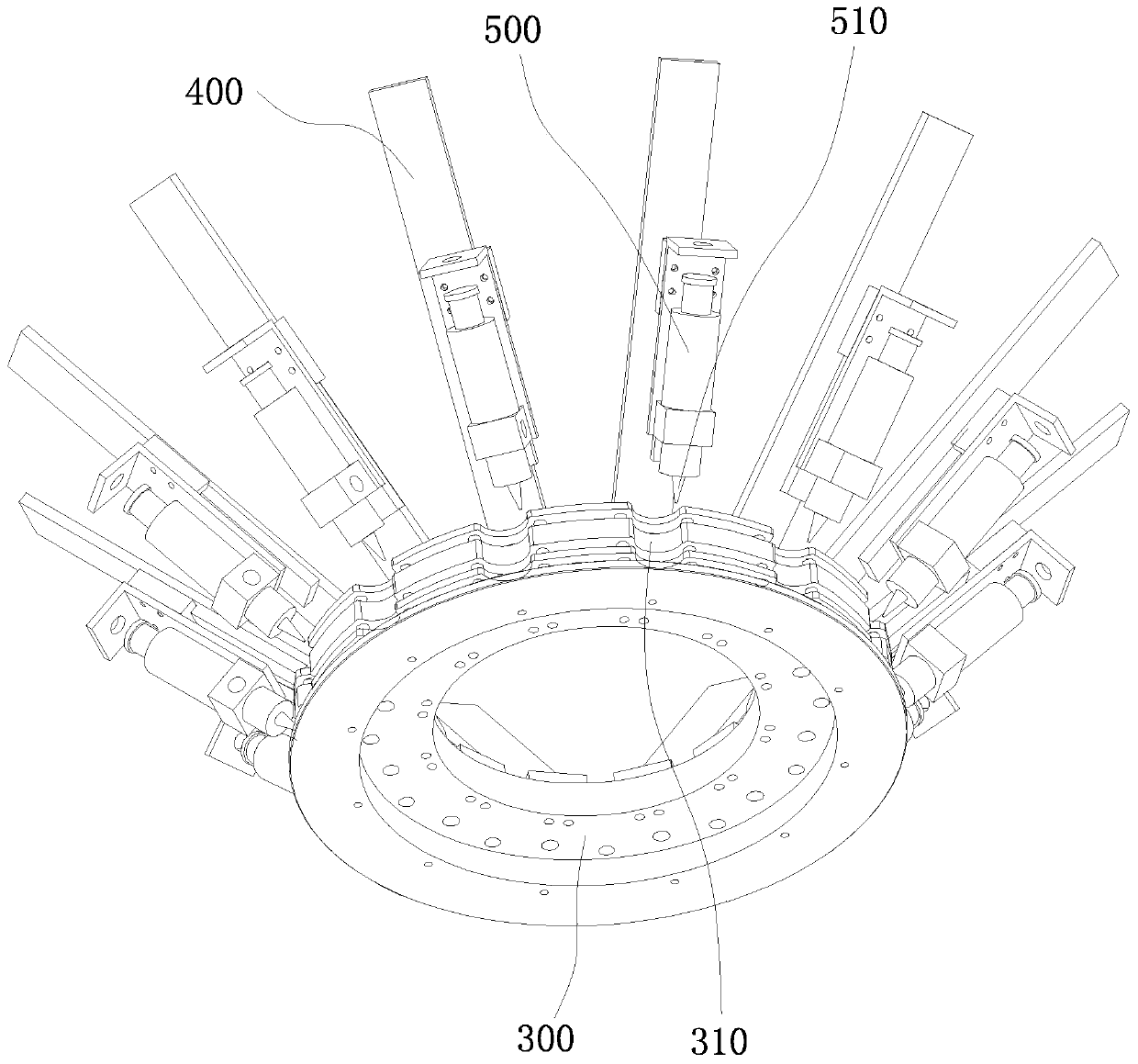

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a coating machine includes: an installation table 200, a coating turntable 300 and a glue valve 500. This coating machine is used in the field of battery production, and its main function is to coat the inner wall of the battery case 100. Glue is applied along the edge to facilitate the installation of the sealing ring and improve the fixation of the sealing ring.

[0032] It is worth noting here that in the existing technical field of battery production, the battery case 100 has a hollow cylindrical structure, and multiple components need to be installed in the battery case 100, among which, the battery case 100 needs to be A sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com