Automatic conveying mechanism for conveying carbon rod

A technology of automatic feeding and driving mechanism, which is applied in the direction of conveyor, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

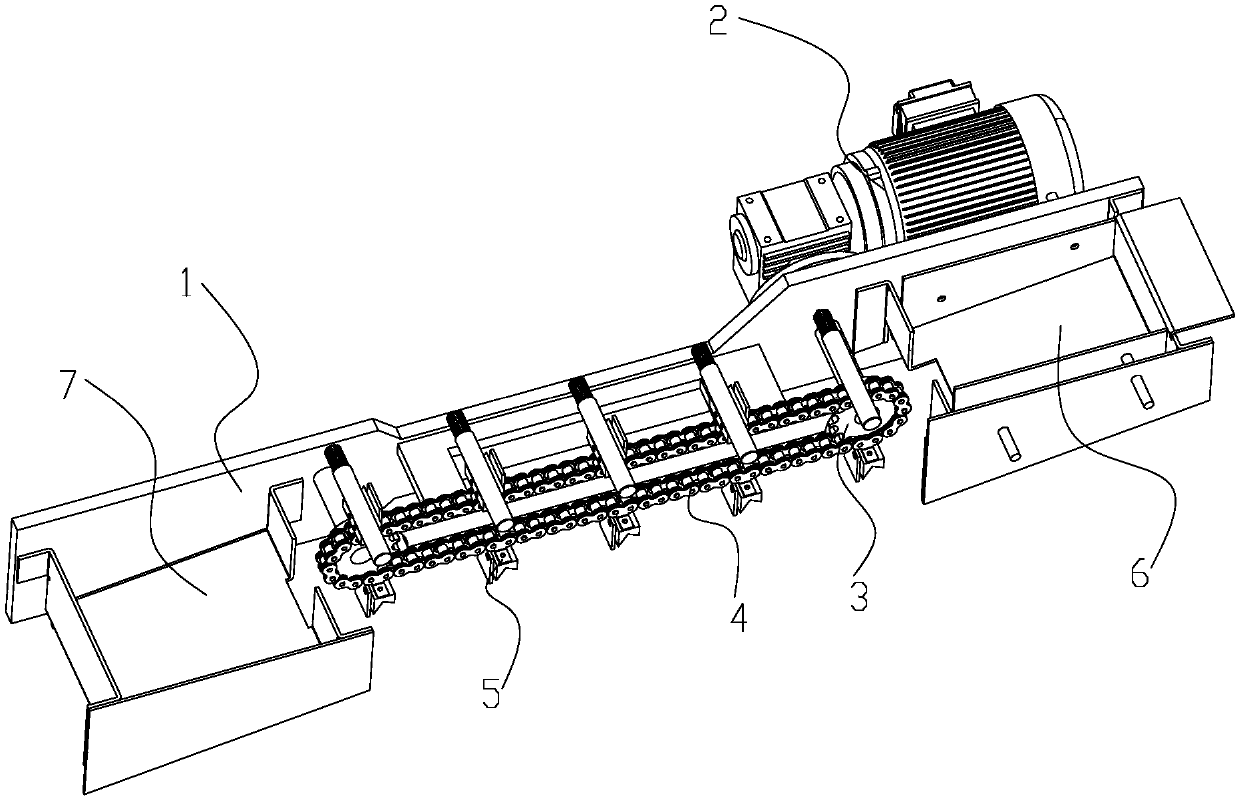

[0029] Such as Figure 1~8 As shown, the present invention provides a kind of automatic feeding mechanism for conveying carbon rods, comprising:

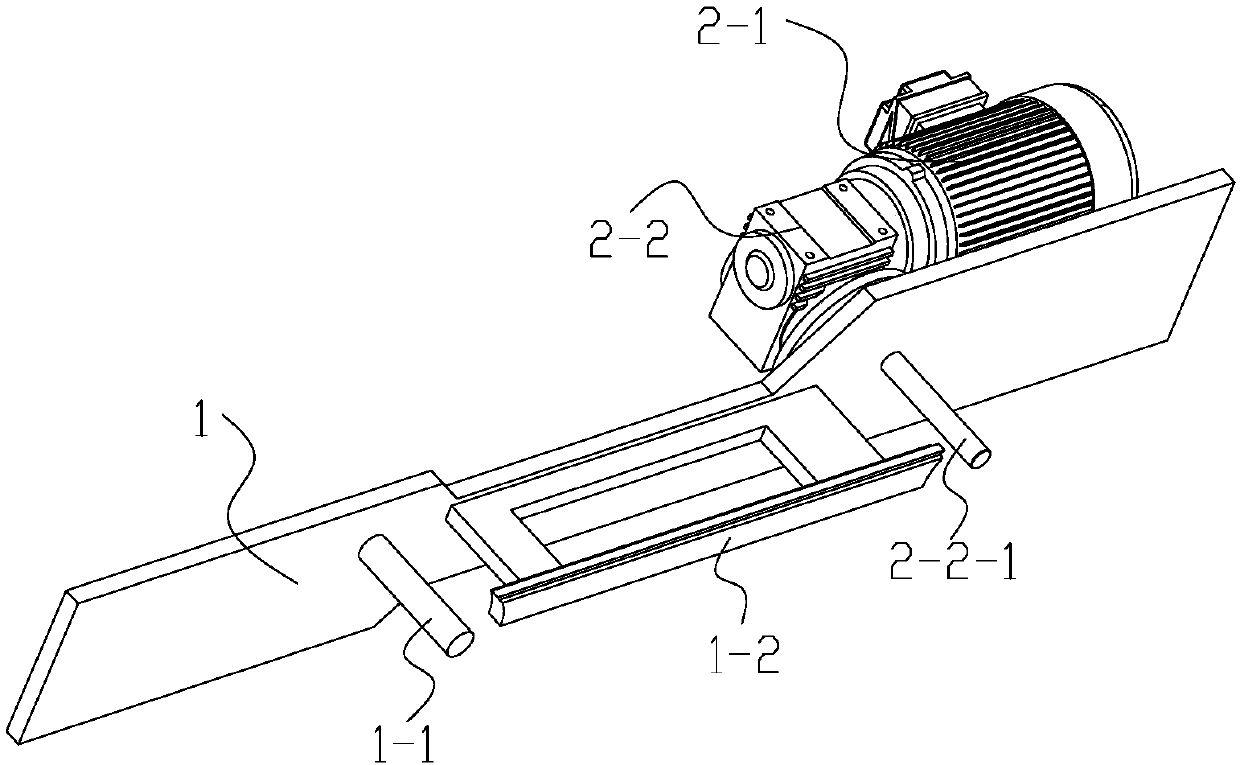

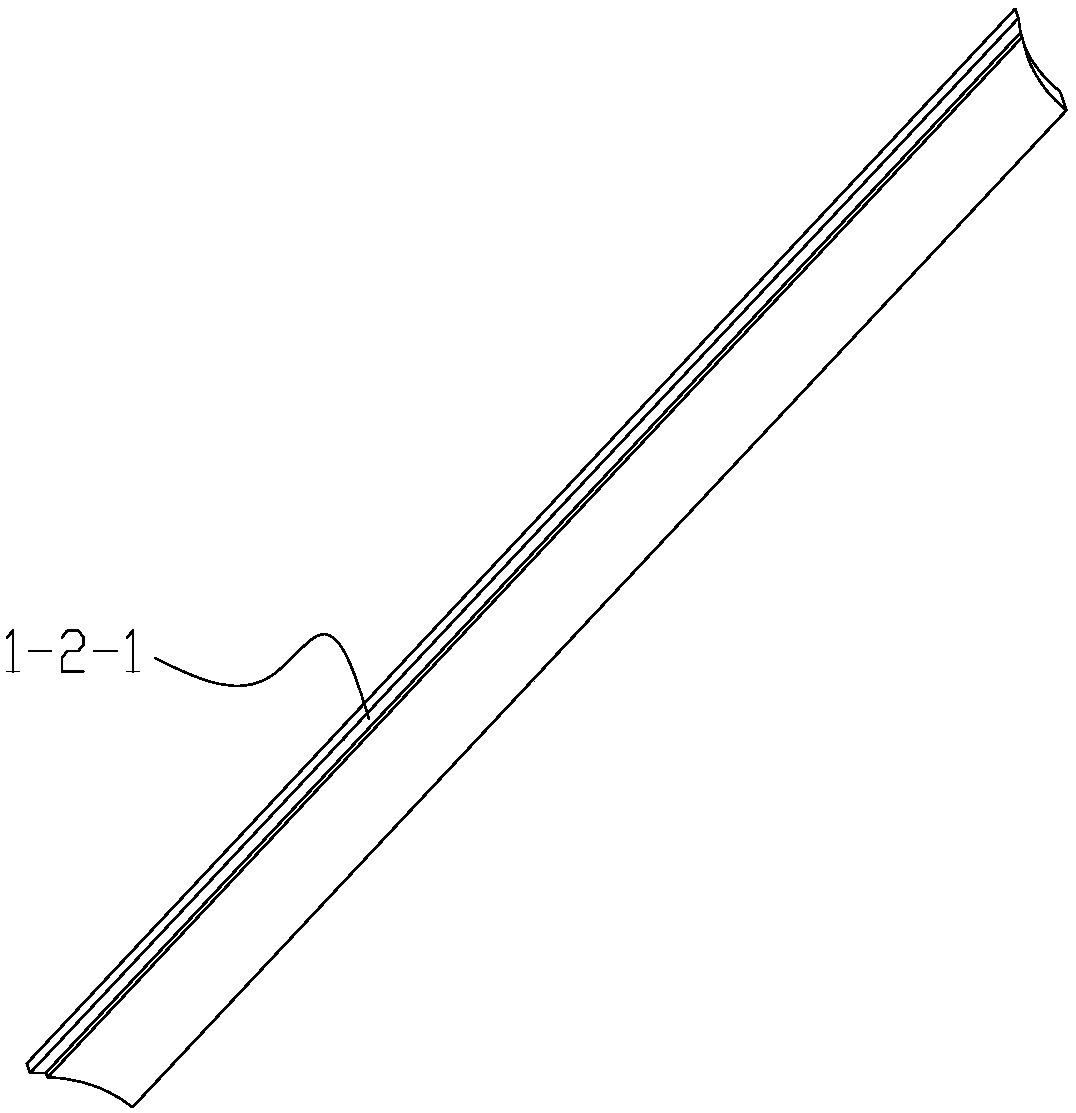

[0030] Shelf plate 1, on which a drive mechanism 2 is fixed, the first output shaft 2-2-1 of the drive mechanism 2 passes through the shelf plate 1, and one side of the shelf plate 1 is extended with an erection column 1-1, the first output The plane where the shaft 2-2-1 and the axis of the erection column 1-1 are located is horizontal, and an erection plate 1-2 is arranged between the two erection columns 1-1, and the erection plate 1-2 is fixedly connected with the erection plate 1, and the erection plate 1-2 is provided with card set convex strip 1-2-1;

[0031] Two sprockets 3, one sprocket 3 is set on the first output shaft 2-2-1, and the other sprocket 3 is rotatably set on the erection column 1-1;

[0032] Chain 4, chain 4 is set on the two sprockets 3, and the raised strip 1-2-1 is set in the chain 4; the chain 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com