Underwater cast-in-situ bored pile reverse circulation efficient hole-forming construction device and method

A technology of bored cast-in-place piles and construction methods, which are applied to underwater drilling, drilling tools, sheet pile walls, etc., can solve the problems of low efficiency of bored cast-in-place piles in water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

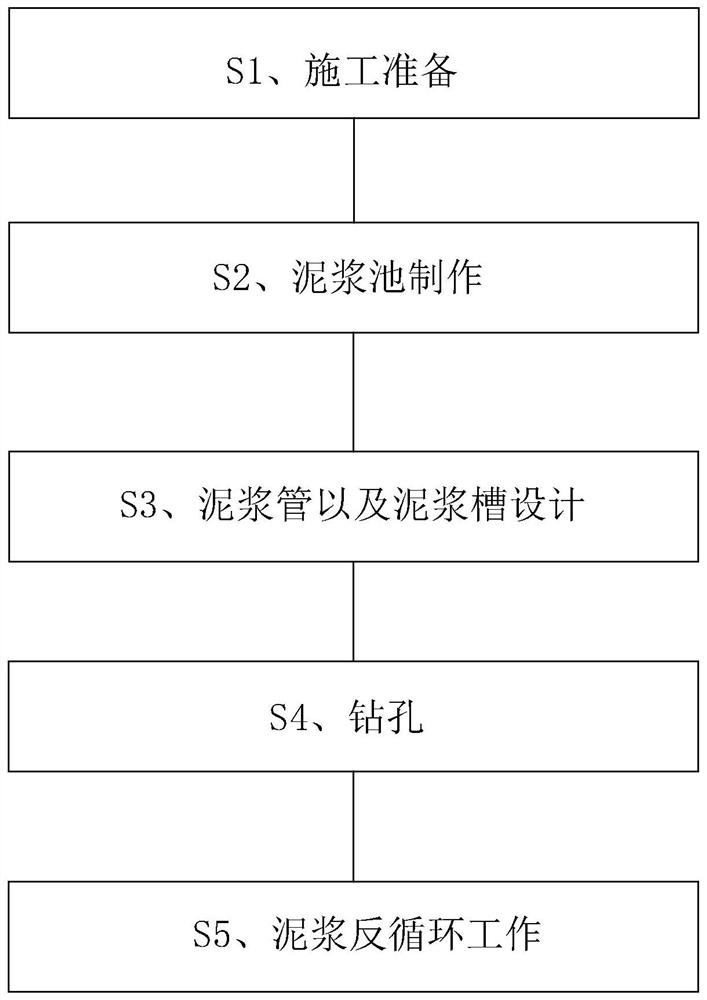

[0045] The embodiment of the present application discloses a construction method for reverse circulation and high-efficiency hole-forming of bored piles in water. refer to figure 1 and figure 2 , the reverse circulation efficient hole-forming construction method of bored piles in water includes the following steps,

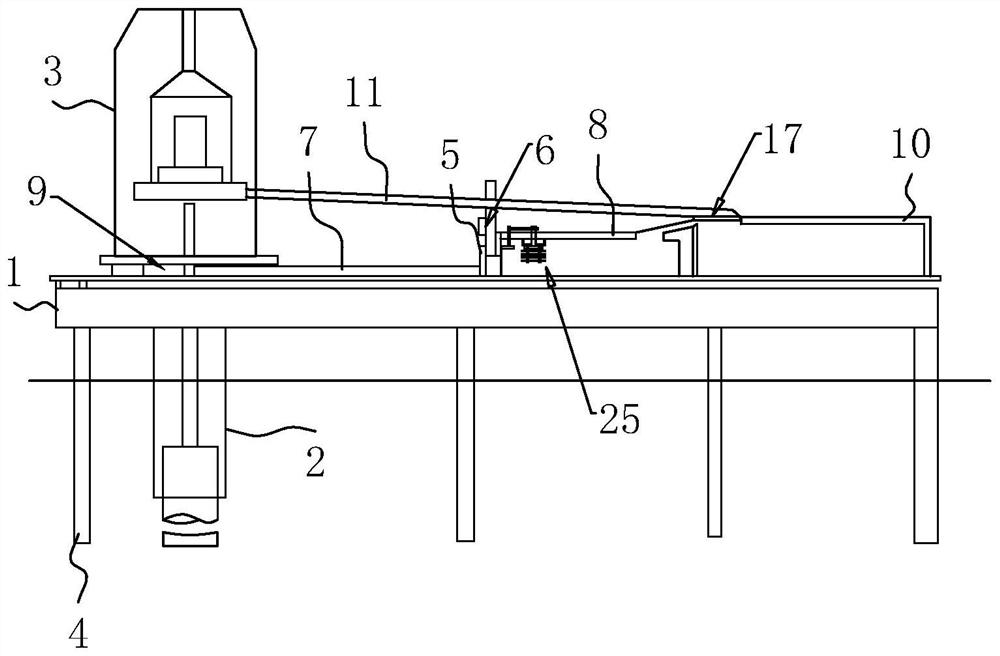

[0046] S1, construction preparation, by driving a plurality of steel pipe piles 4 in the water, the drilling platform 1 is erected above the steel pipe piles 4, and the entire drilling platform 1 is located above the horizontal plane, and then a steel casing 2 is drilled at the borehole , use a crane as a lifting device, cooperate with a vibrating hammer to insert and drill the steel casing 2, and the steel casing 2 enters the bearing layer to ensure the safety of the construction process. The drilling rig 3 is arranged on the drilling platform 1 and is located above the steel casing 2;

[0047]S2. Fabrication of the mud pool 8. Install the mud pool 8 on the dr...

Embodiment 2

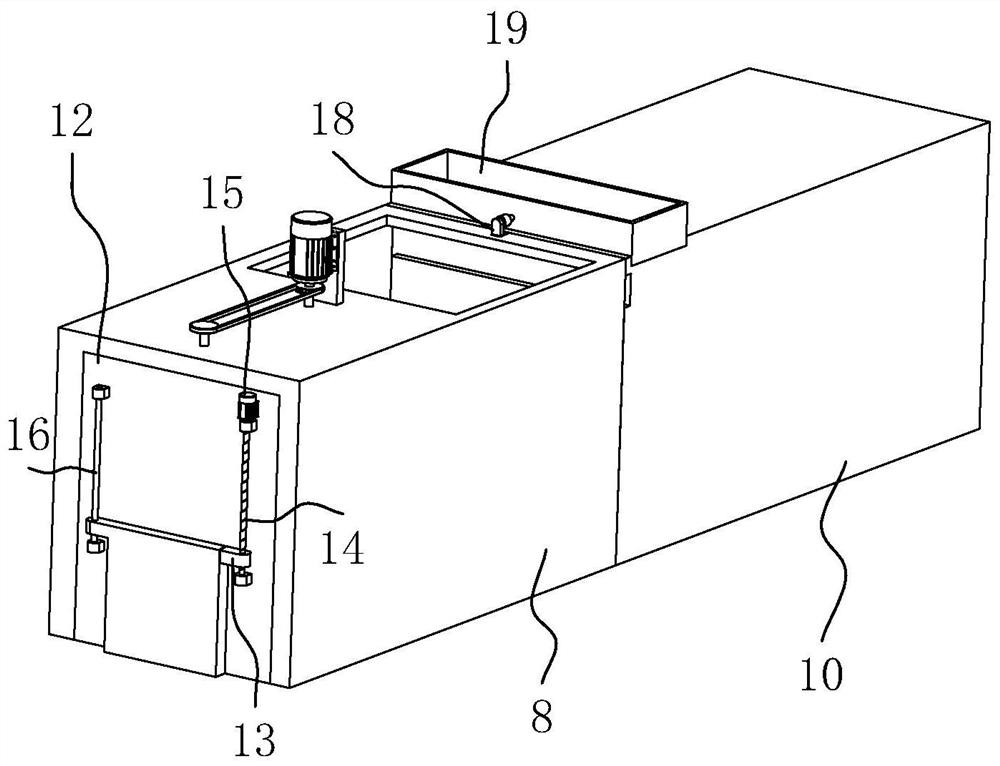

[0054] The embodiment of the present application also discloses a reverse circulation and high-efficiency hole-forming construction device for bored piles in water. refer to figure 2 and Figure 4 The reverse circulation high-efficiency pore-forming construction device for bored piles in water includes a filter device 17 arranged at the entrance of the sedimentation tank 10. Since the mud carries part of the drilling debris, in order to facilitate filtering of impurities in the mud, the filter device 17 includes The filter frame 18 fixedly connected to the sedimentation tank 10 and the filter screen 19 detachably arranged with the filter frame 18, the filter screen 19 is located at the entrance of the sedimentation tank 10, and the size of the end face of the filter screen 19 is equal to the size of the entrance of the sedimentation tank 10. When transporting When the pipe 11 transports the mud to the opening of the sedimentation tank 10, under the filtering action of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com